Email us

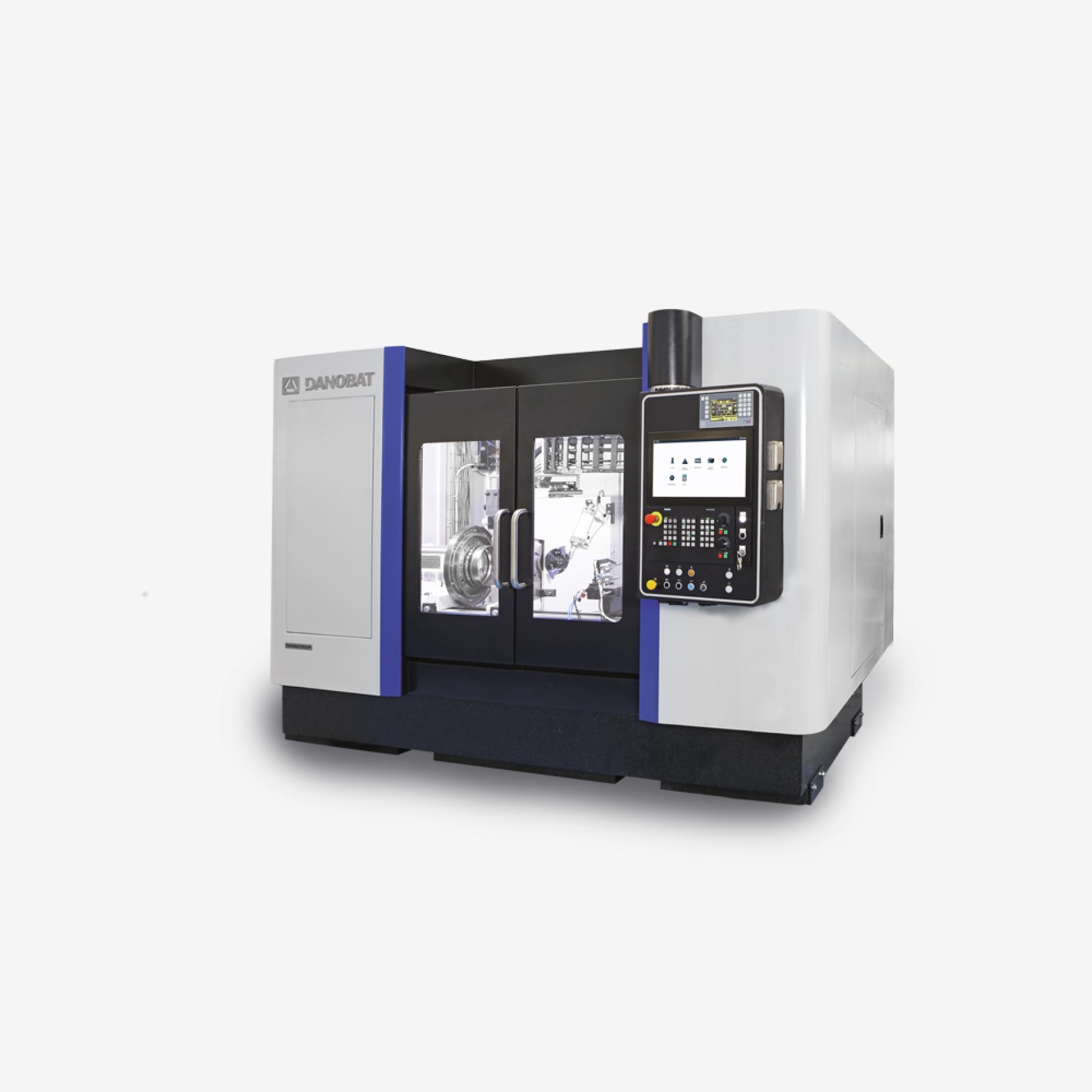

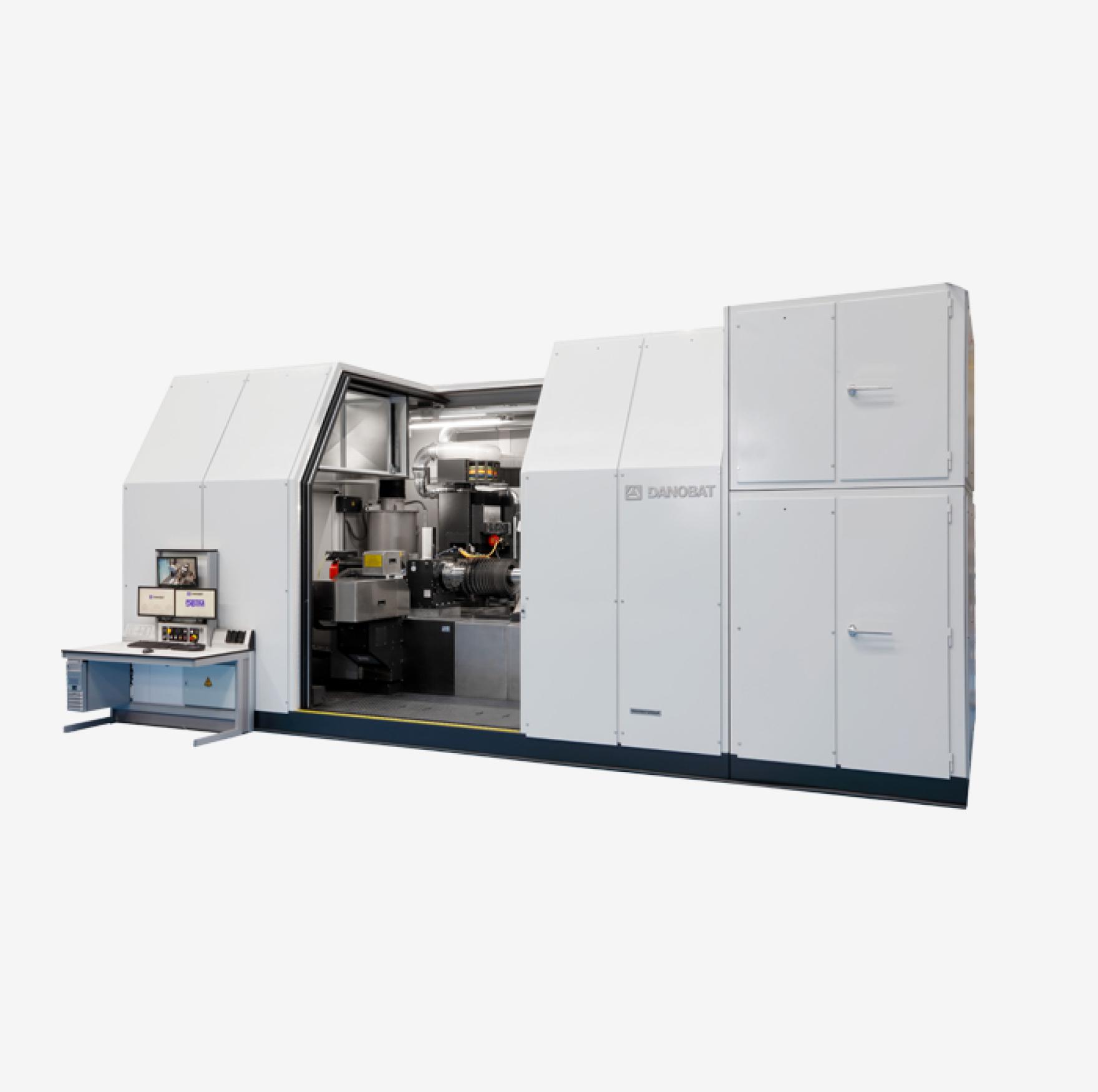

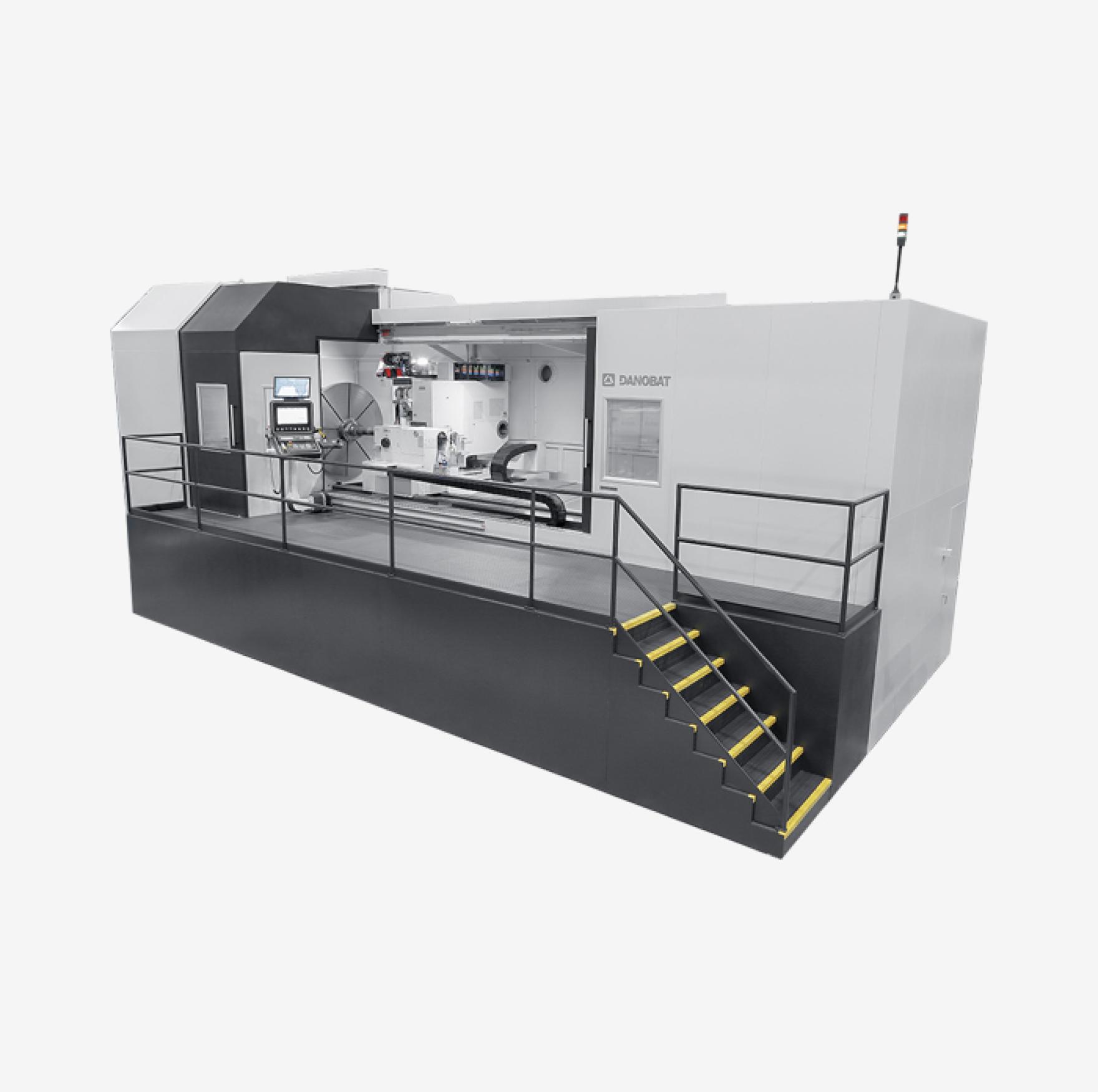

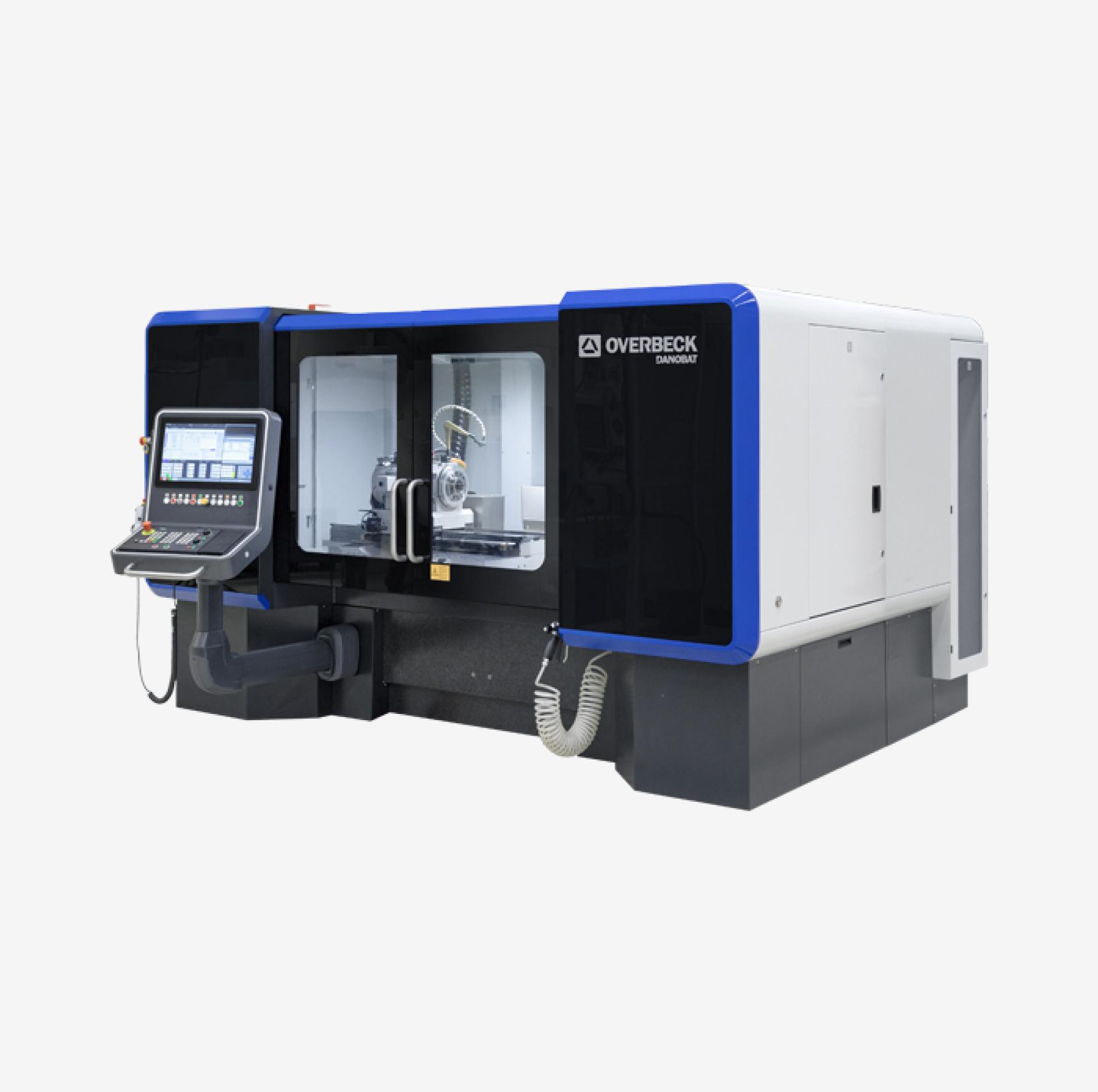

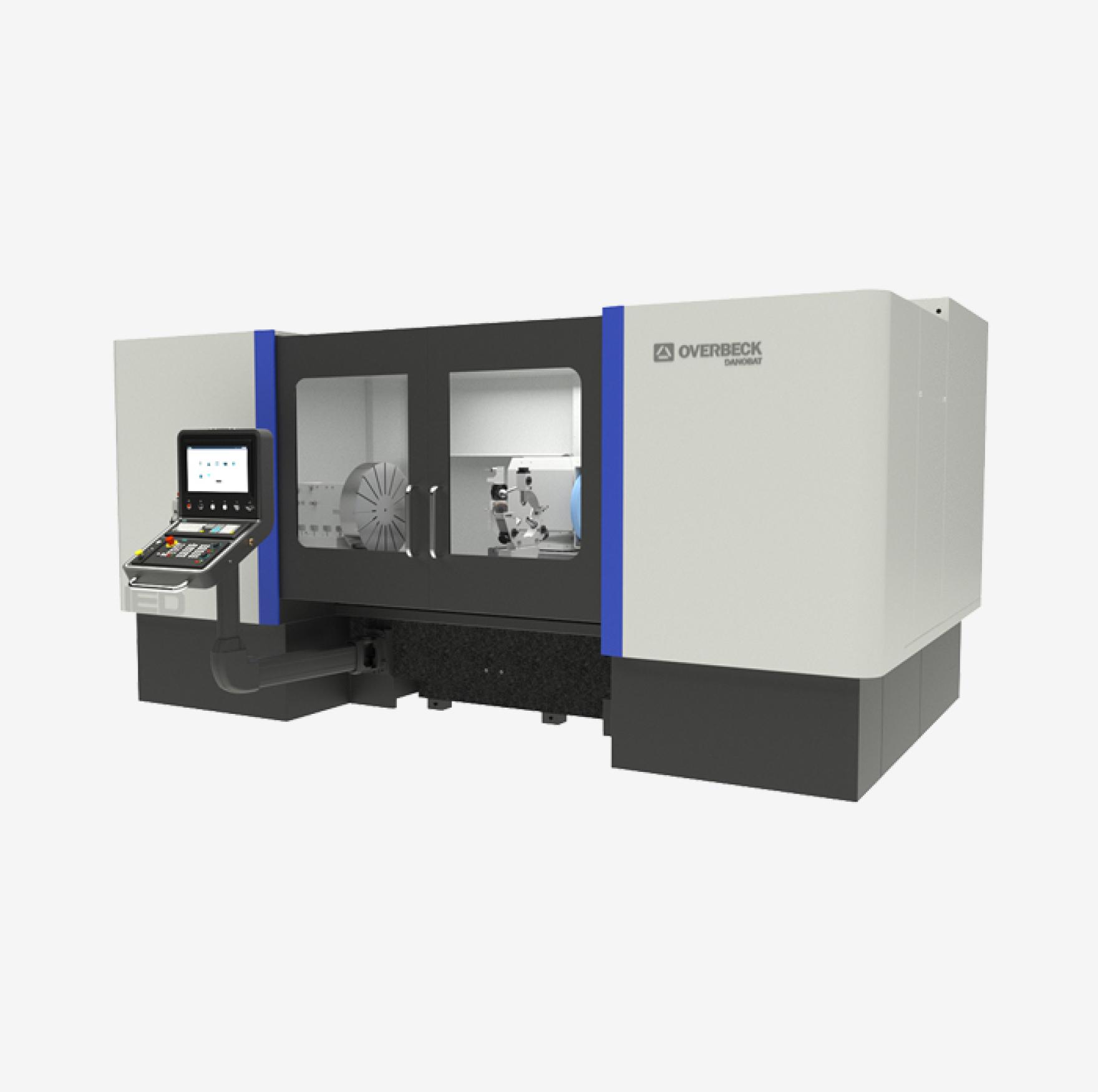

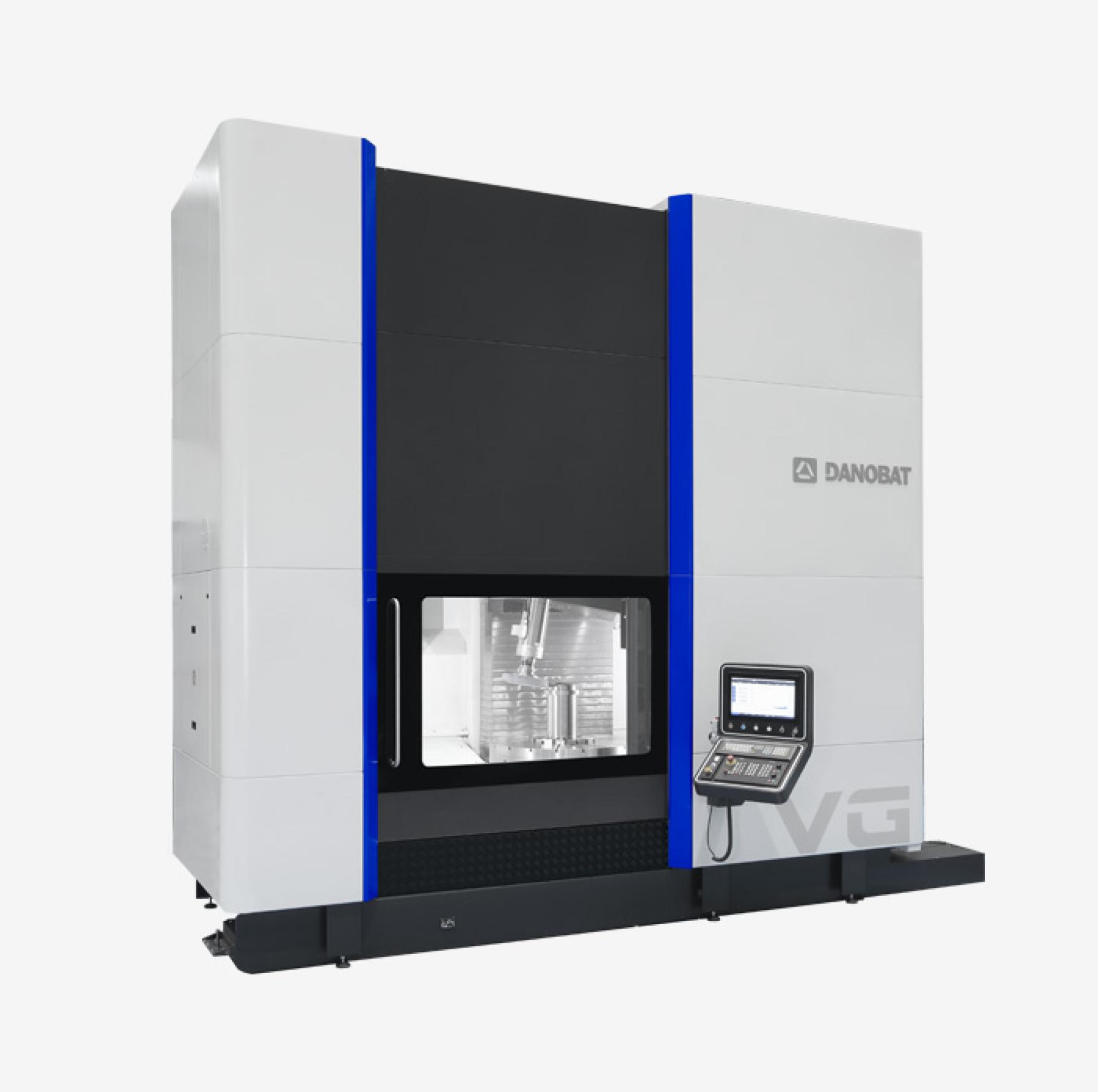

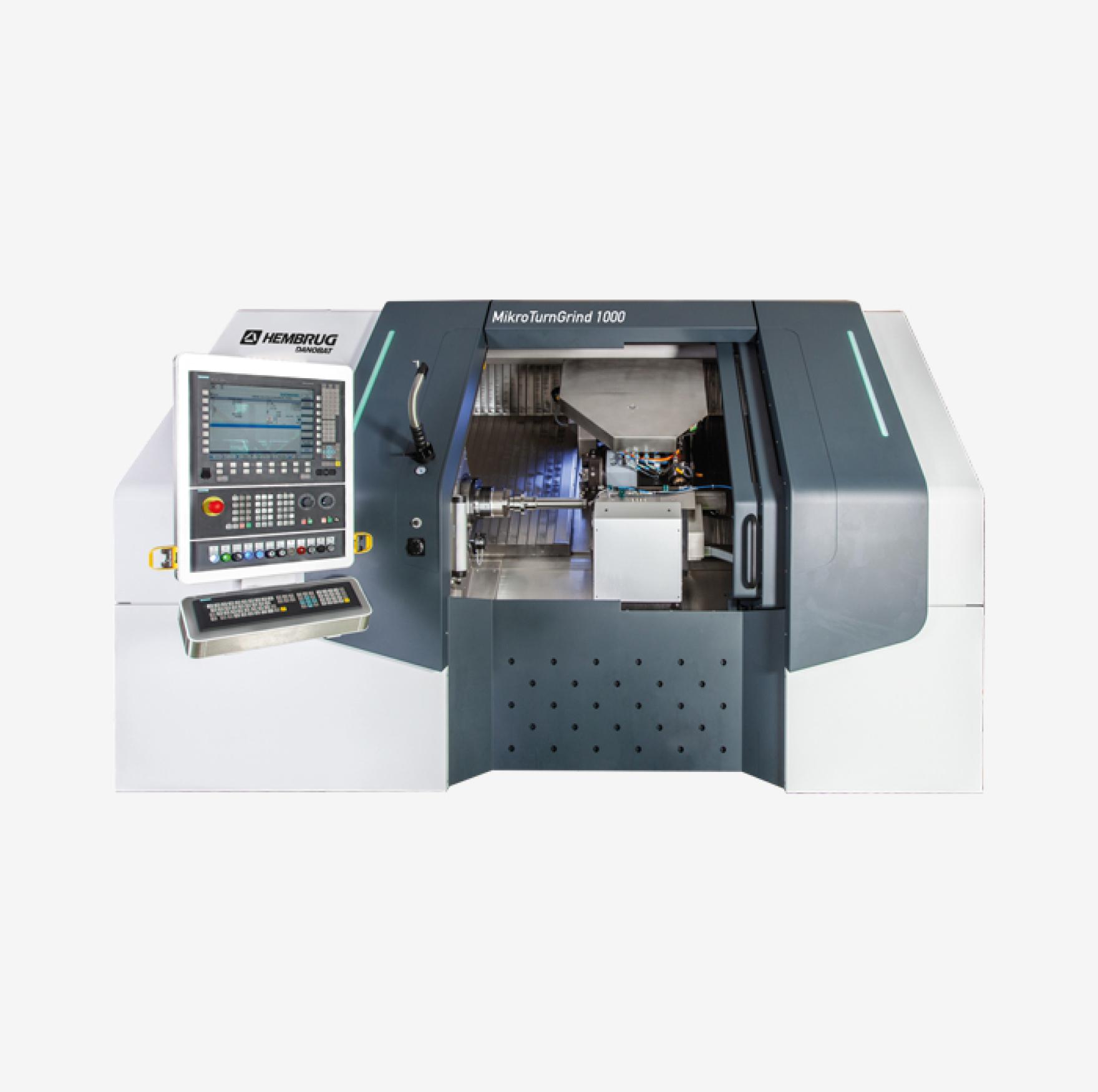

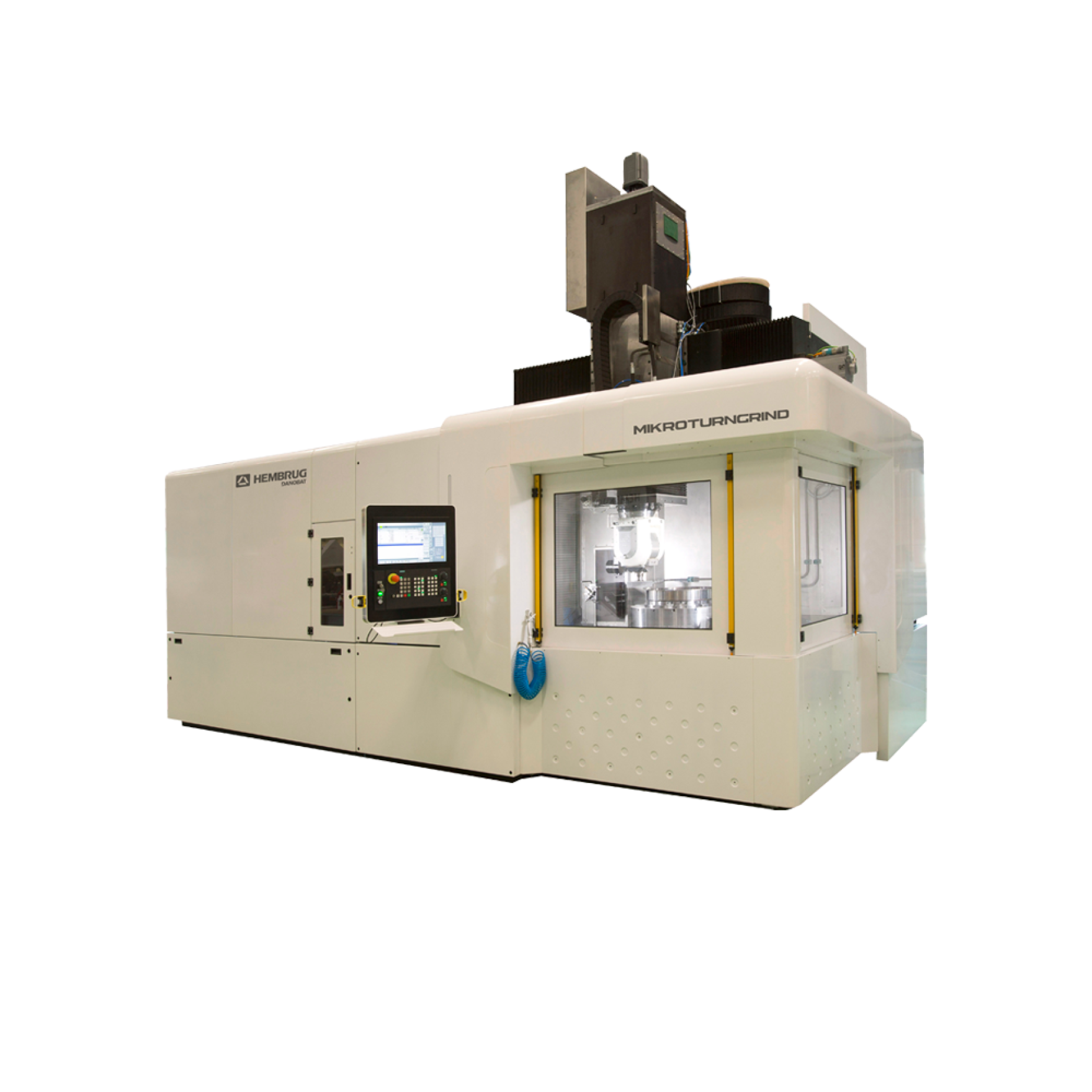

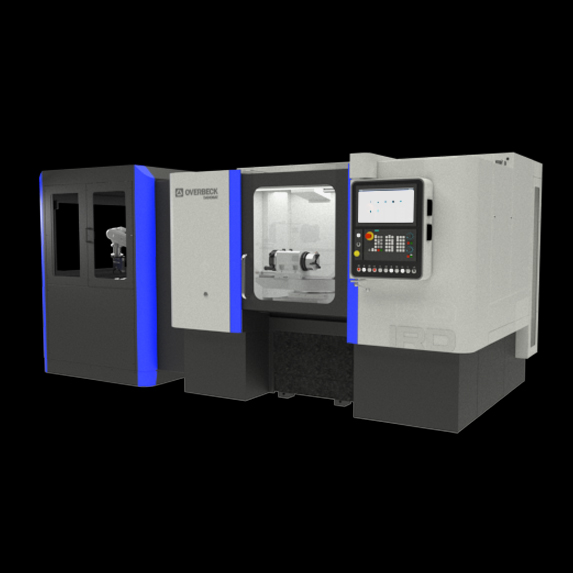

PG

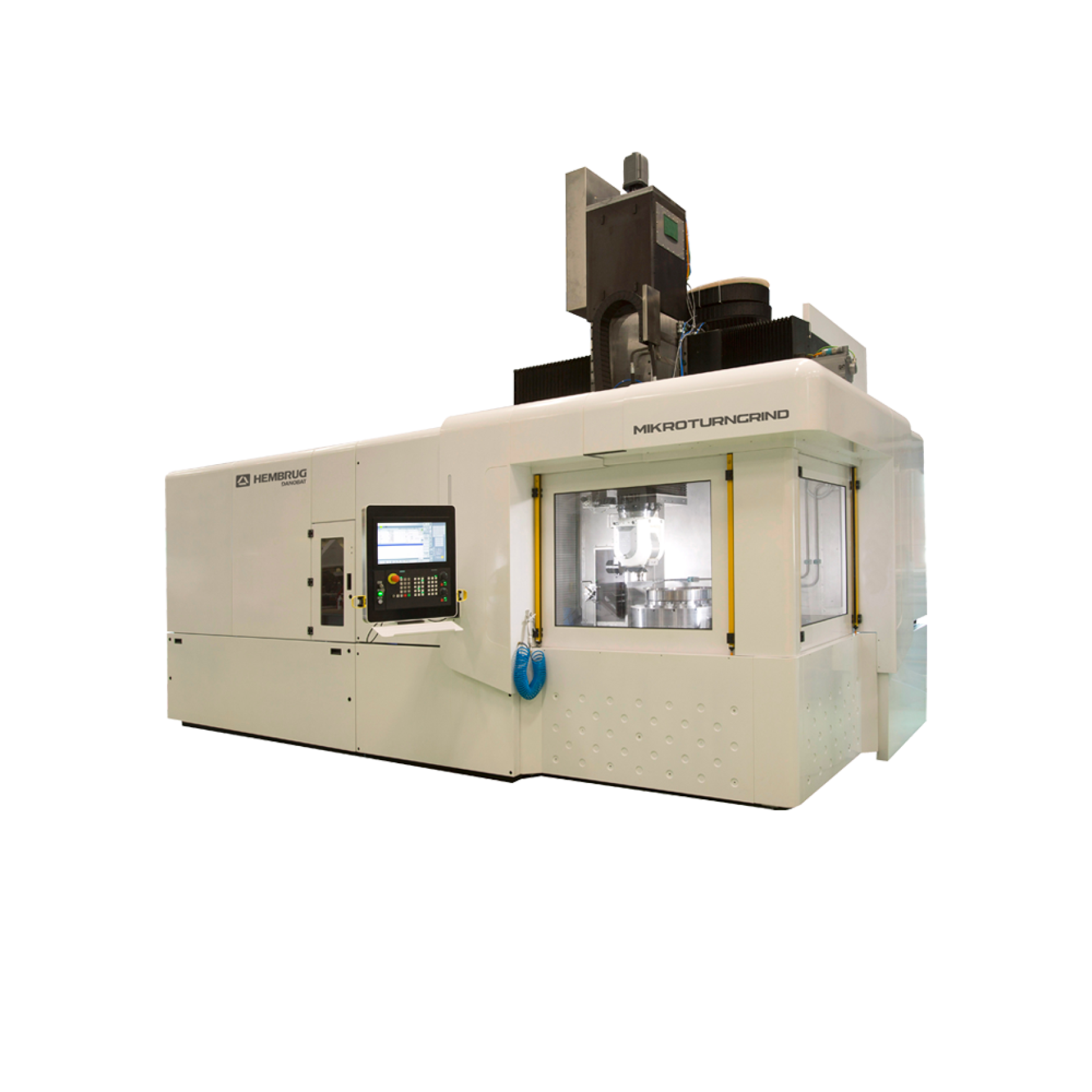

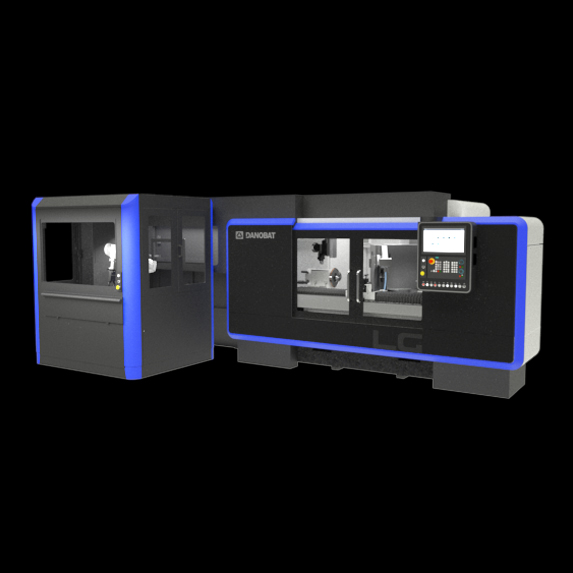

MASS PRODUCTION GRINDING MACHINE

The PG is a machine for standardized parts in mass production.

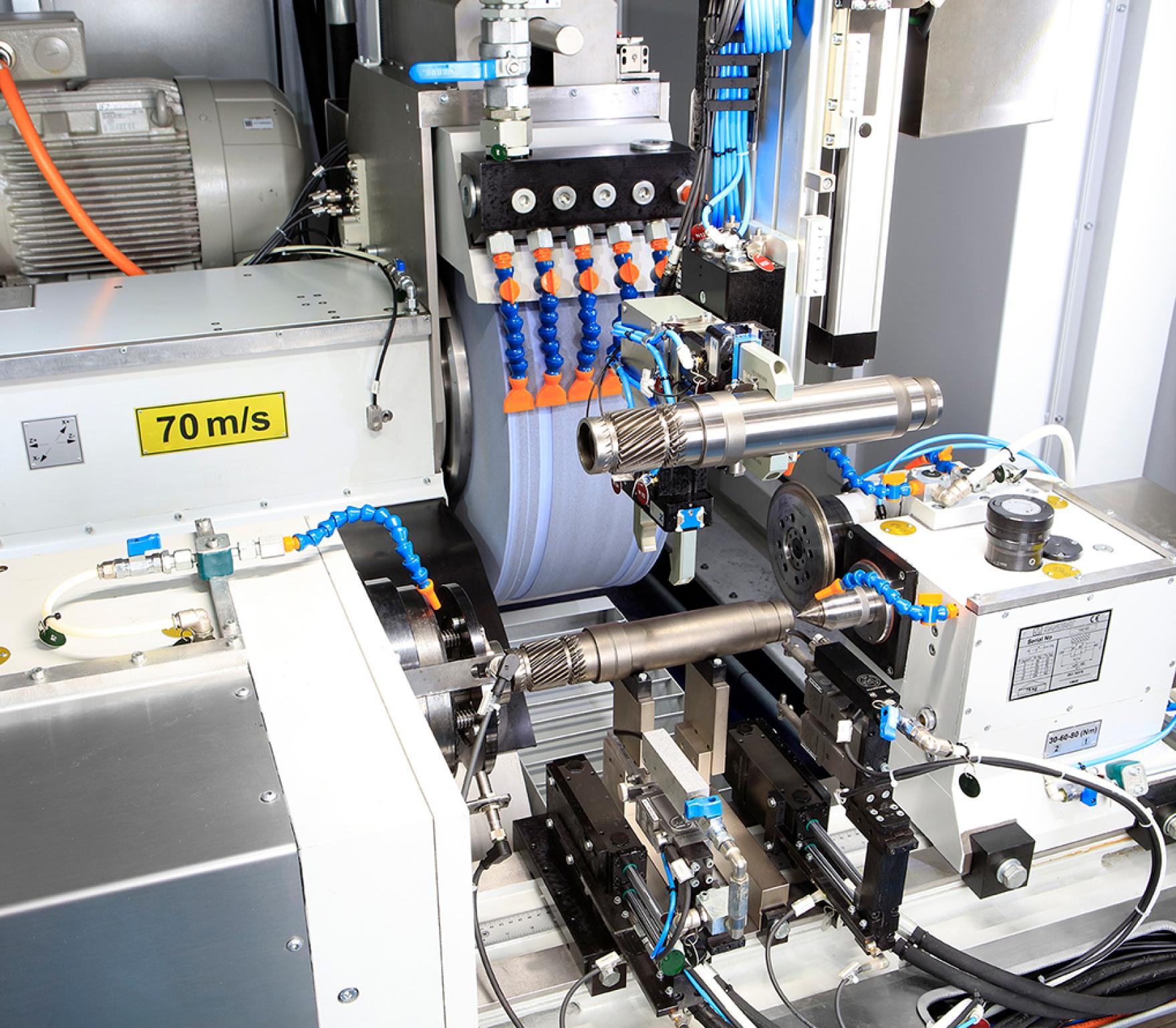

Due to the tremendous stiffness of the machine structure, you can use bigger grinding wheels (up to Ø36" — Ø915 mm —) to get higher efficiency.

Highlights

For single workpiece mass-production

A machine dedicated to making a single part with the following dimensions:

39.37”

1100 lb

15750 sfpm

Corundum

Ø17”

Ø36”

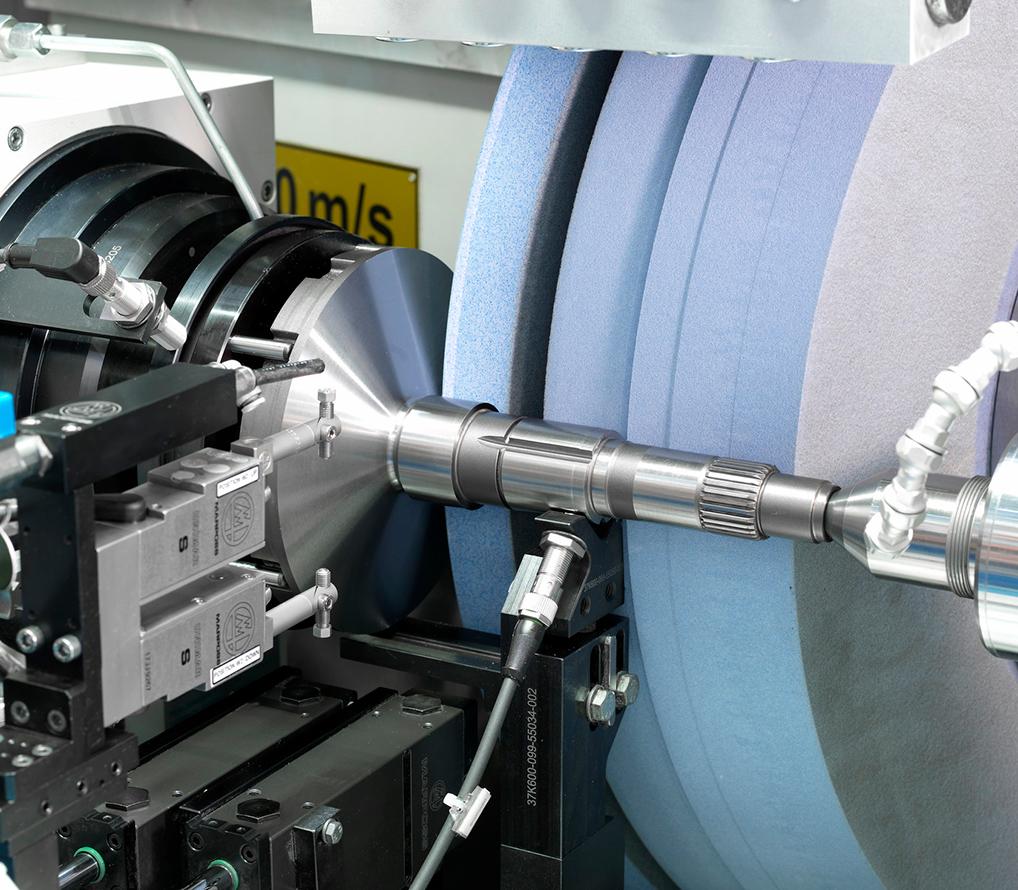

Technology

When we talk about high production, every detail matters

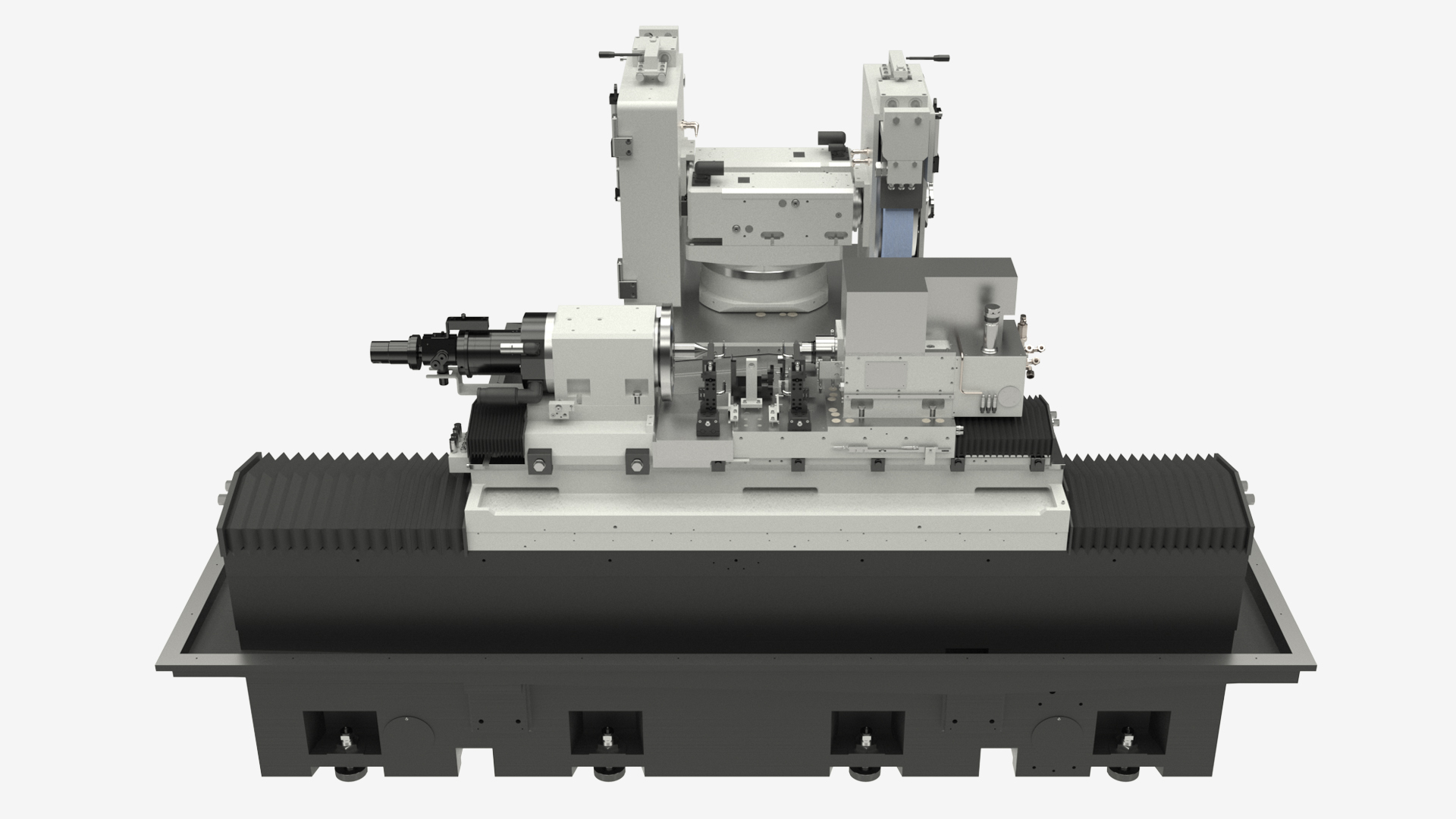

Machine structure

- Unique and rigid structure

- Made of stress-relieved pearlitic cast iron for optimum grinding accuracy

- Coolant channels for thermal stability

- Proven behaviour against vibration and thermal effects

X and Z axes

- Hydrostatic V and flat slideways

- The slide is driven by a ballscrew with direct coupling to a CNC controlled servomotor

- A high resolution absolute linear scale controls the positioning

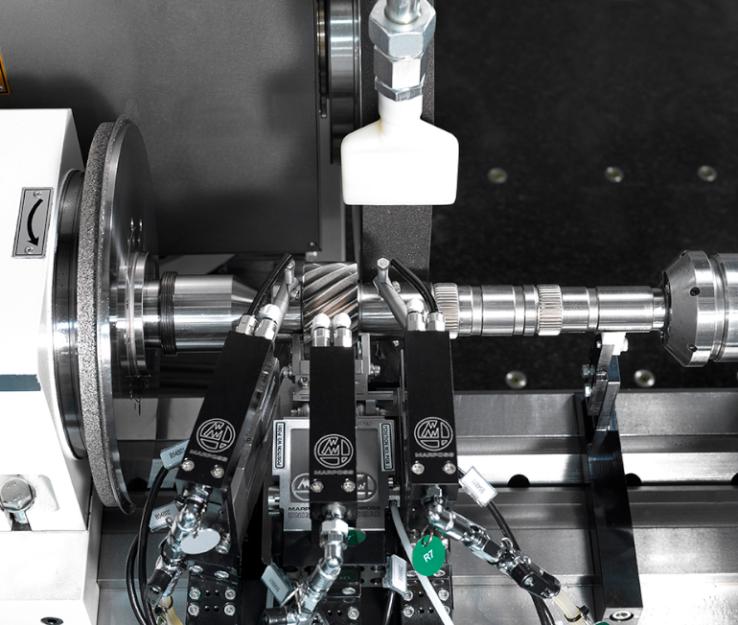

Workhead & tailstock

- Rigid castings, made in modular designs with selected materials for stable temperature performance

- Compressed air lifting systems for comfortable set-ups, and easy repositioning of the tailstock along the table

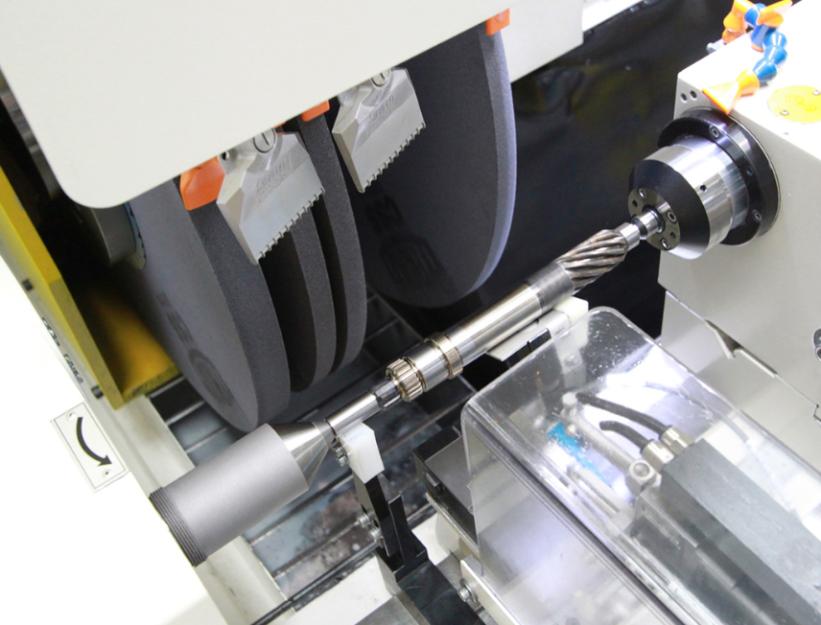

Grinding spindle heads

- Mounted on proven ultra precision bearings (hydrostatic optionally) with lifetime grease lubrication

- Driven by built-in electro-spindles

Swivelling B Axis

Automatic swivelling, driven through a torque motor, and controlled by high resolution rotary encoder.

It can position in any angle, with a mechanical locking and pneumatic unlocking system.

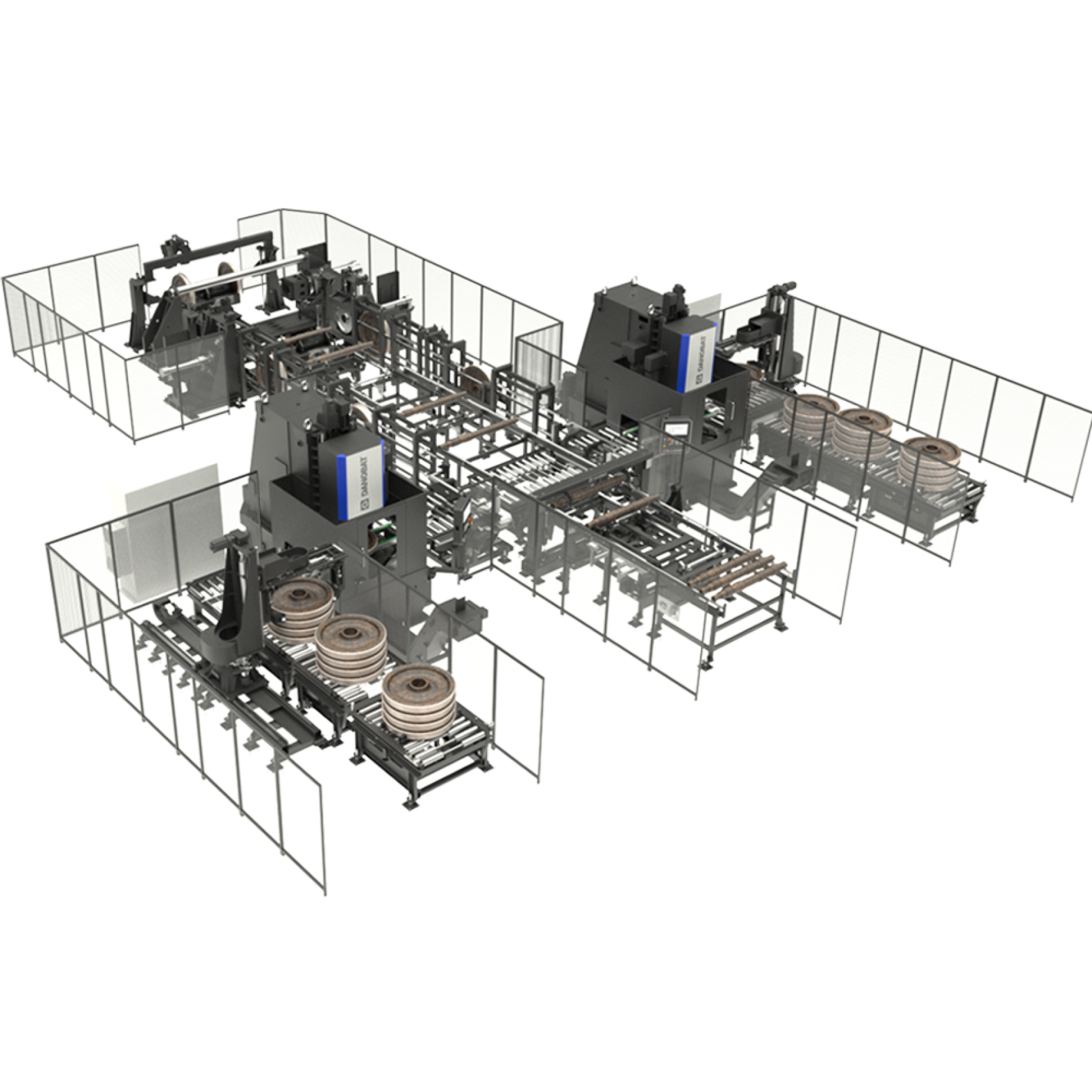

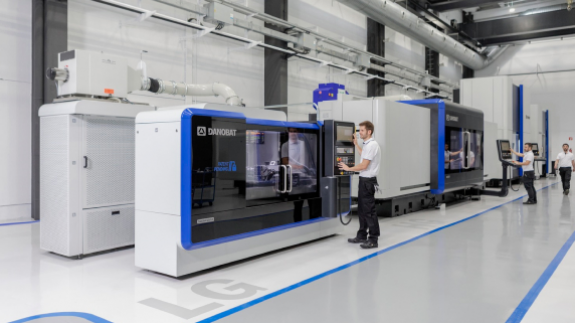

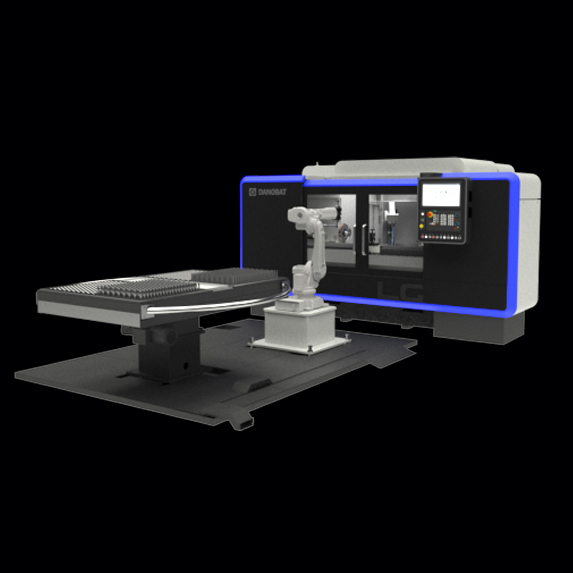

Automation

Do you want to reduce cost per part?

We can offer you a machine including (un)loading systems, feeding or storage systems, and auxiliary stations.

Technical data

| PG-600 | PG-1000 | ||

|---|---|---|---|

| Max. distance between centers | mm | 600 | 1000 |

| Max. diameter to be ground | mm | 440 | 440 |

| Max. weight between centers | kg | 500 | 500 |

| Max. grinding wheel diameter | mm | Ø760 x 350 | Ø910 x 200 |

| Max. wheel peripheral speed | m/s | 80 | 80 |

| PG-600 | PG-1000 | ||

|---|---|---|---|

| Max. distance between centers | in | 23.62 | 39.37 |

| Max. diameter to be ground | in | 17 | 17 |

| Max. weight between centers | lb | 1100 | 1100 |

| Max. grinding wheel diameter | in | Ø30 x 13.8 | Ø36 x 7.8 |

| Max. wheel peripheral speed | sfpm | 16000 | 16000 |

Workpieces

Service

We offer specific services for your PG

- We have programs to exchange your damaged or worn spindle for one we have in stock to eliminate downtime

- Remote machine diagnosis: Keep your machine connected and analyse the vibration threshold of your machine spindles

- Customized maintenance plans based on your production needs: laser interferometry tests, measuring equipment calibration and much more

- Updated catalog of upgrades (electronic & mechanical) to improve your OEE, reduce maintenance times, and avoid obsolescence

Digital

Are you interested in enhancing machine maintenance and machining processes?

Image gallery

Off