Email us

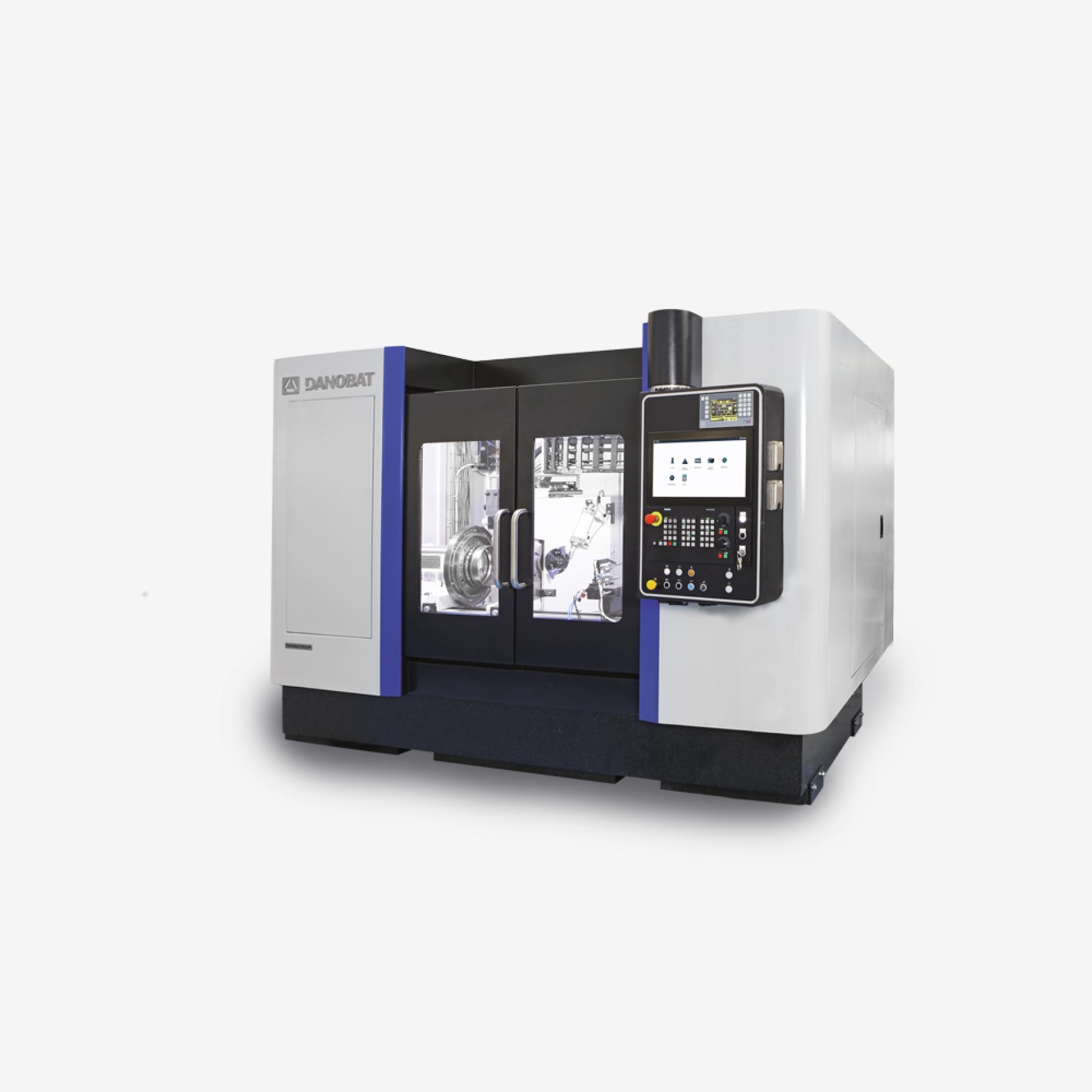

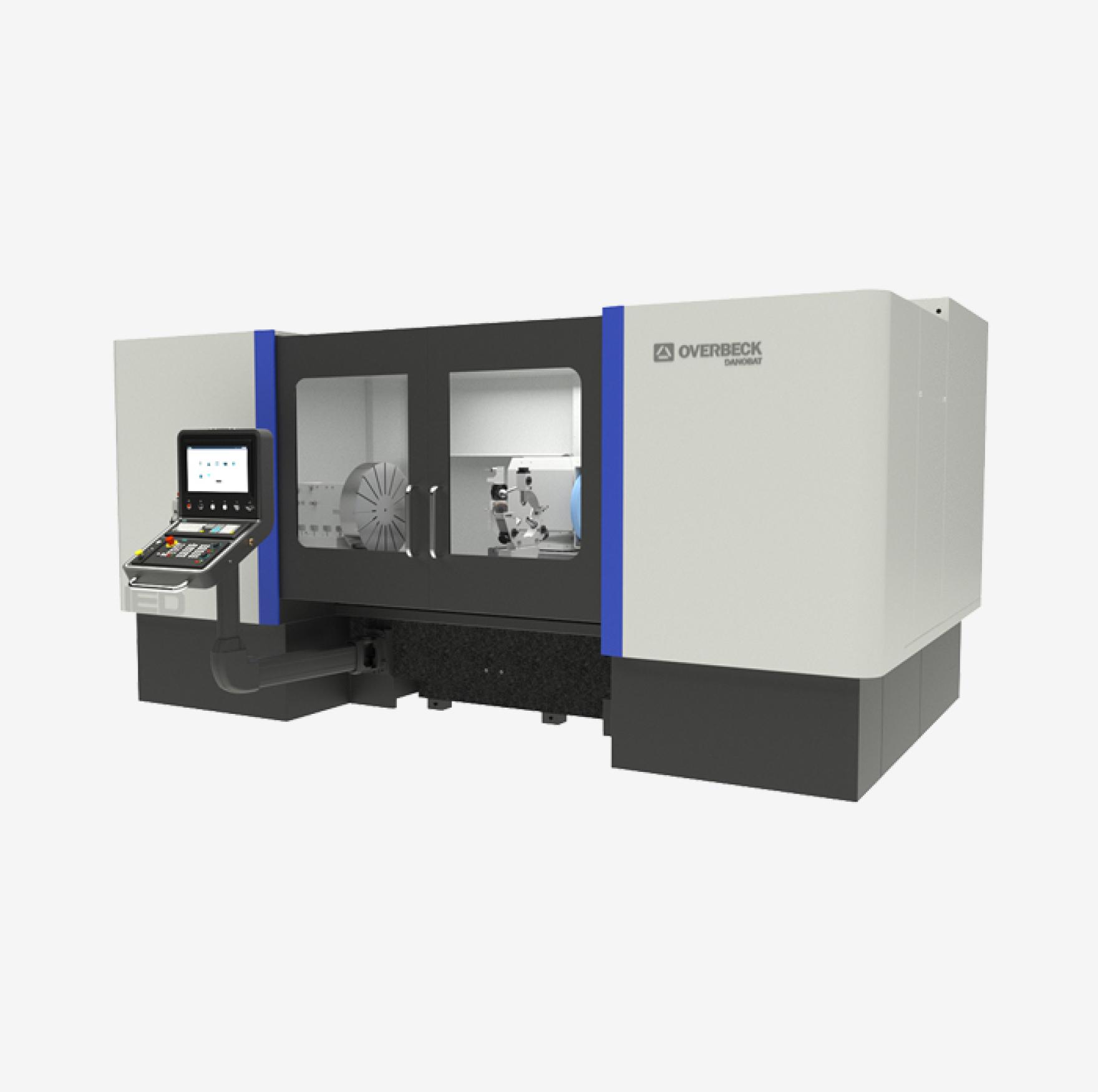

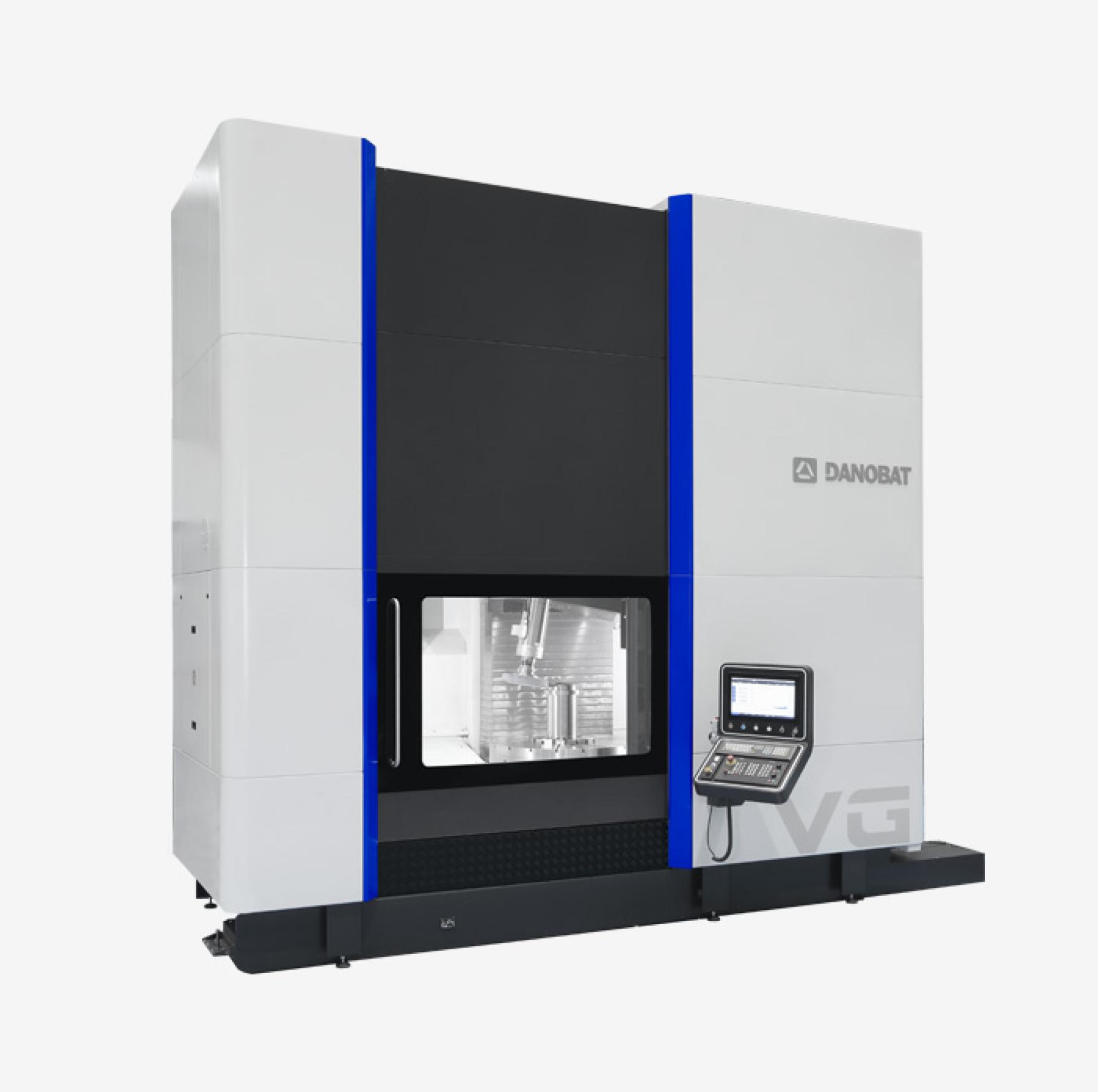

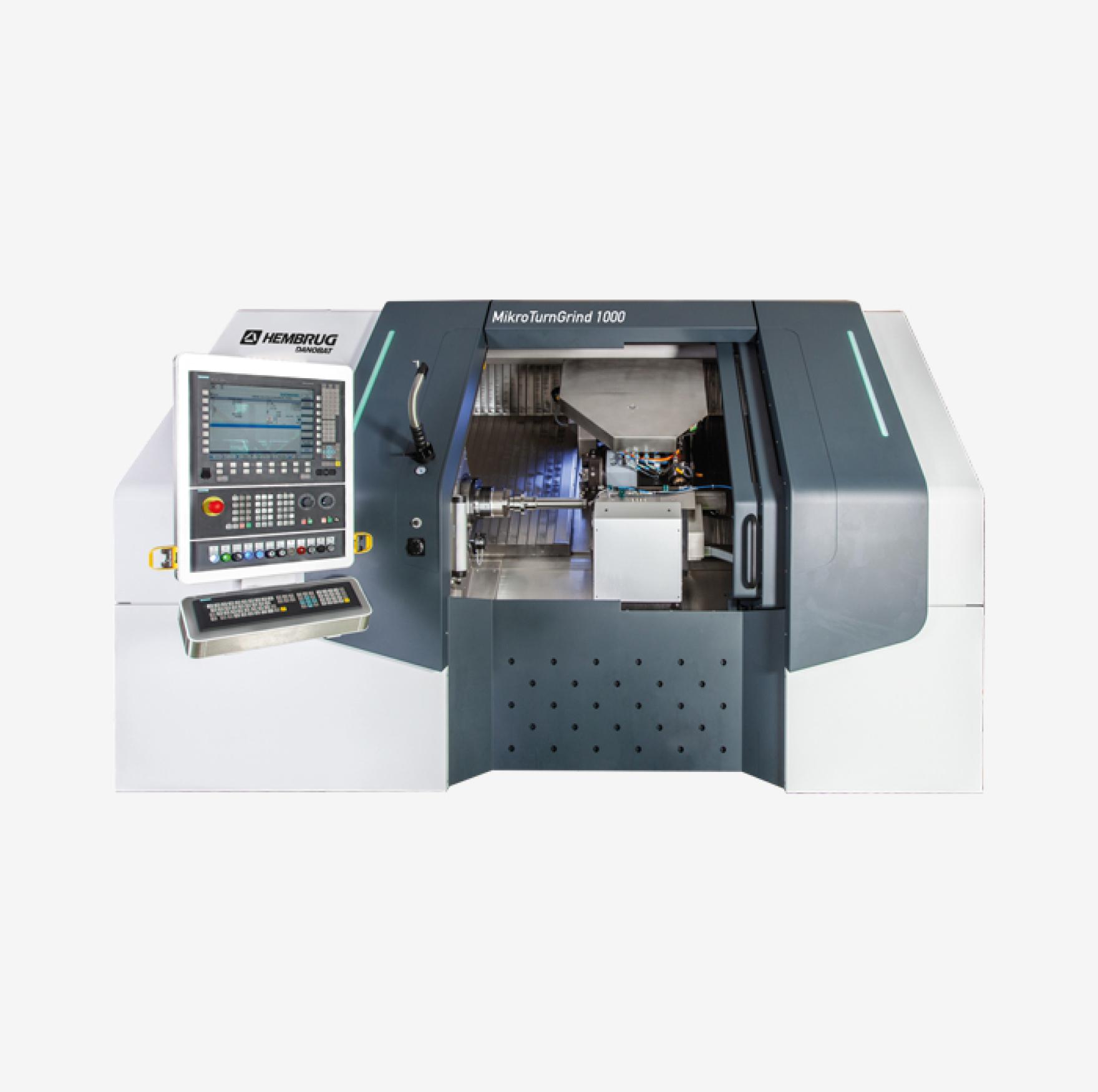

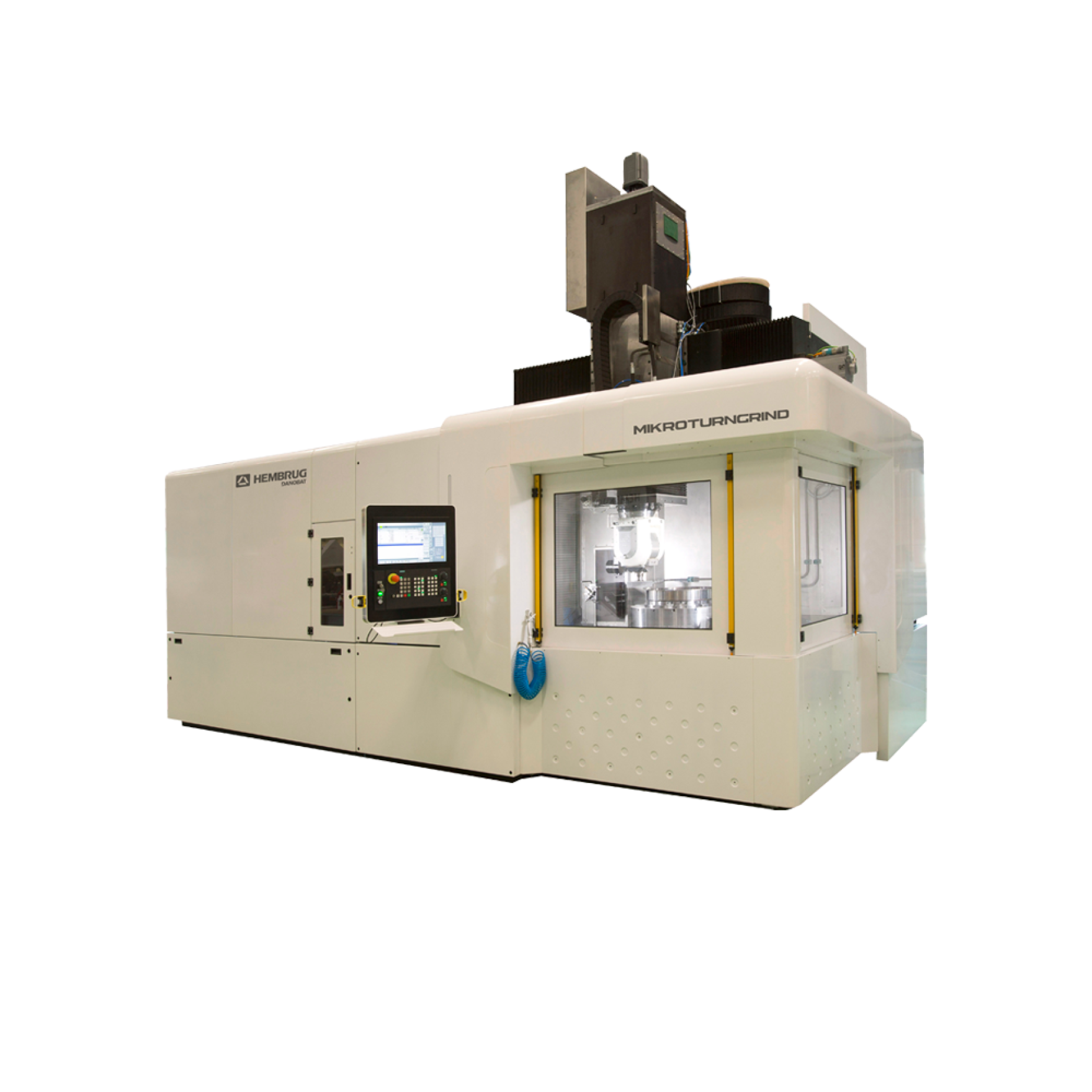

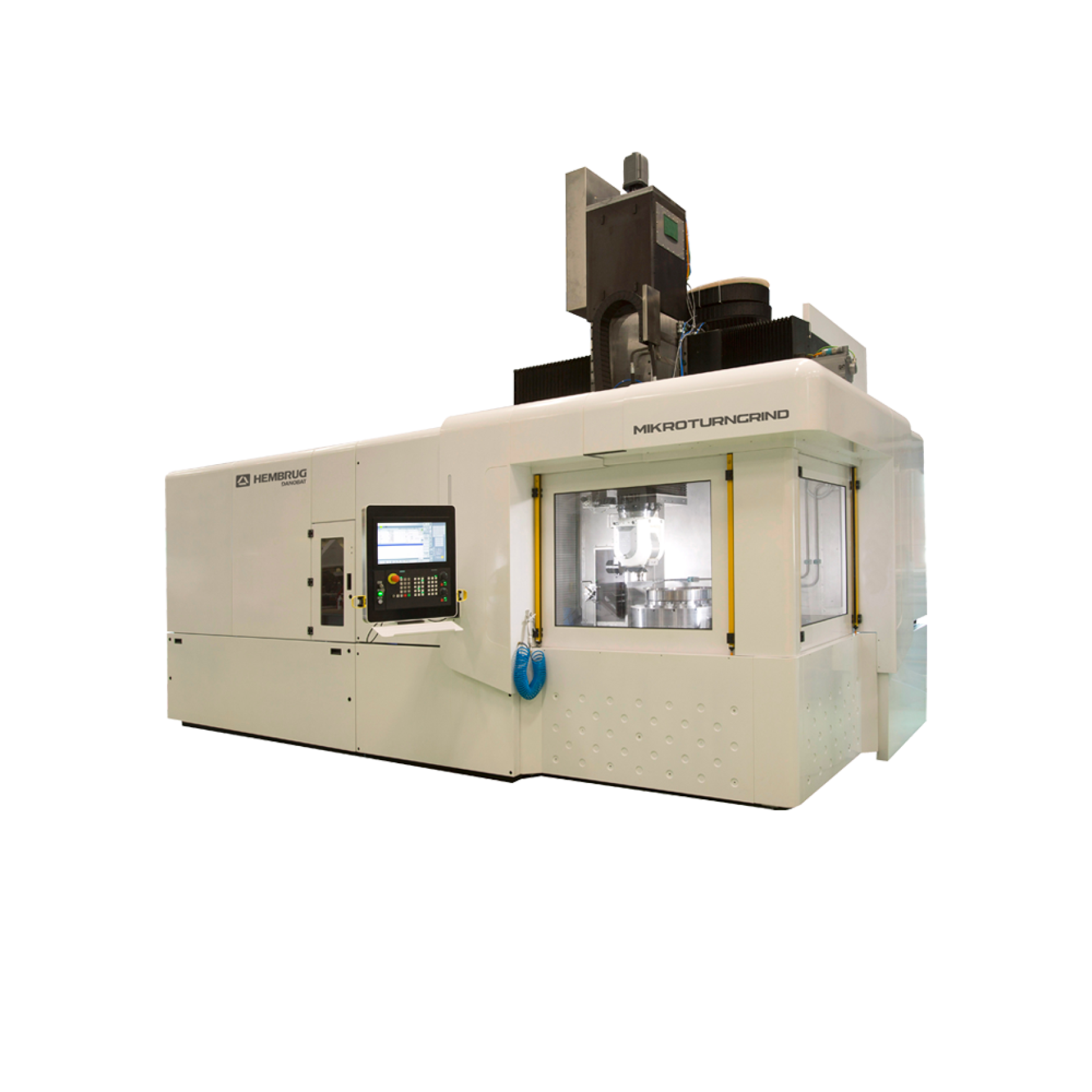

HYBRID VERTICAL TURNING AND GRINDING MACHINE

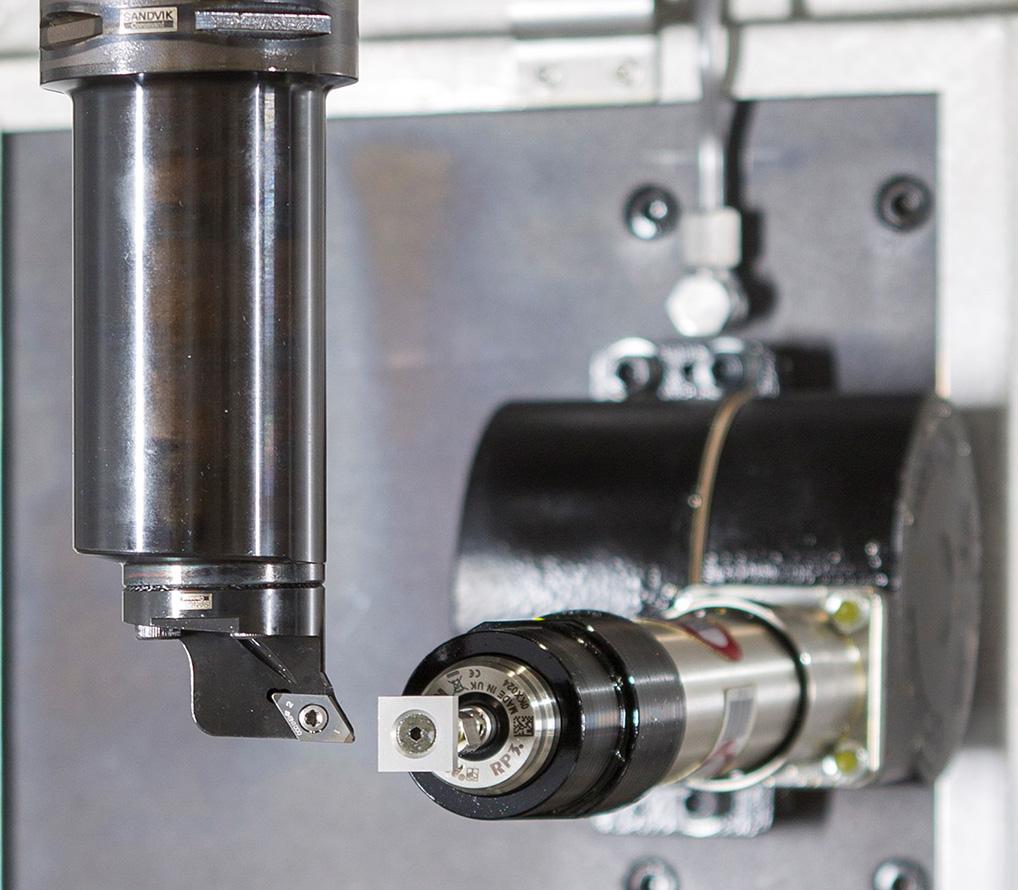

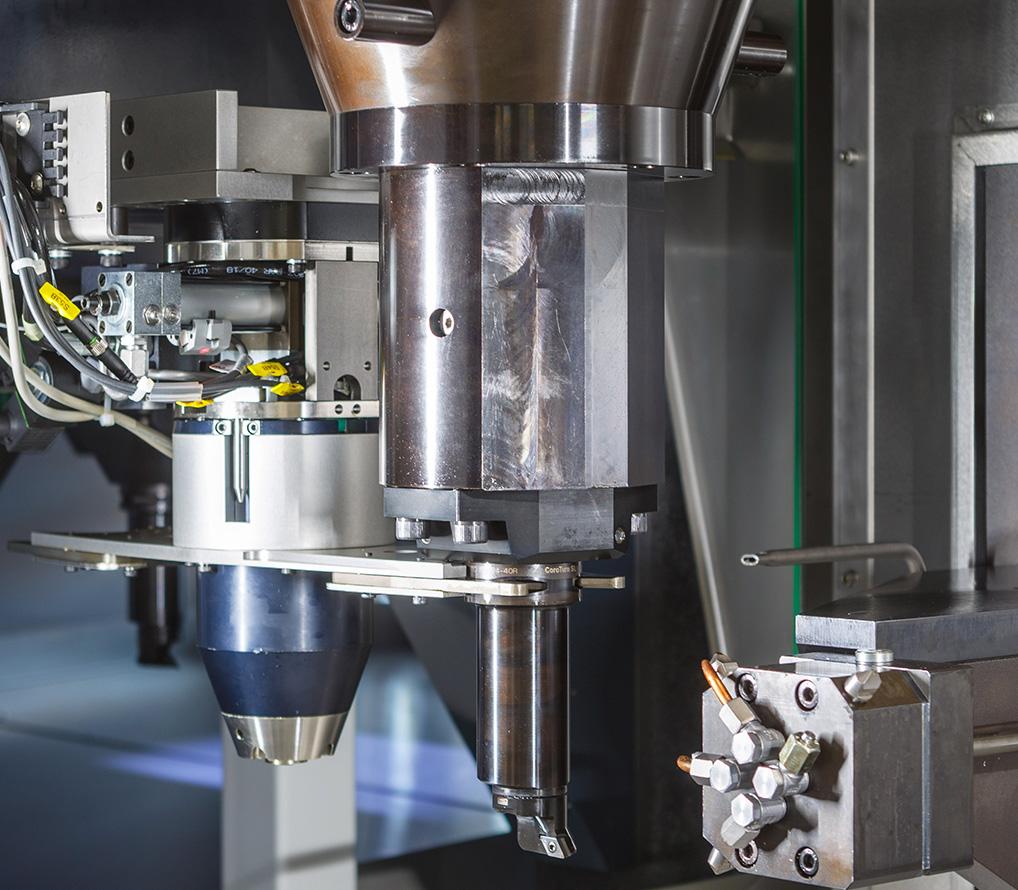

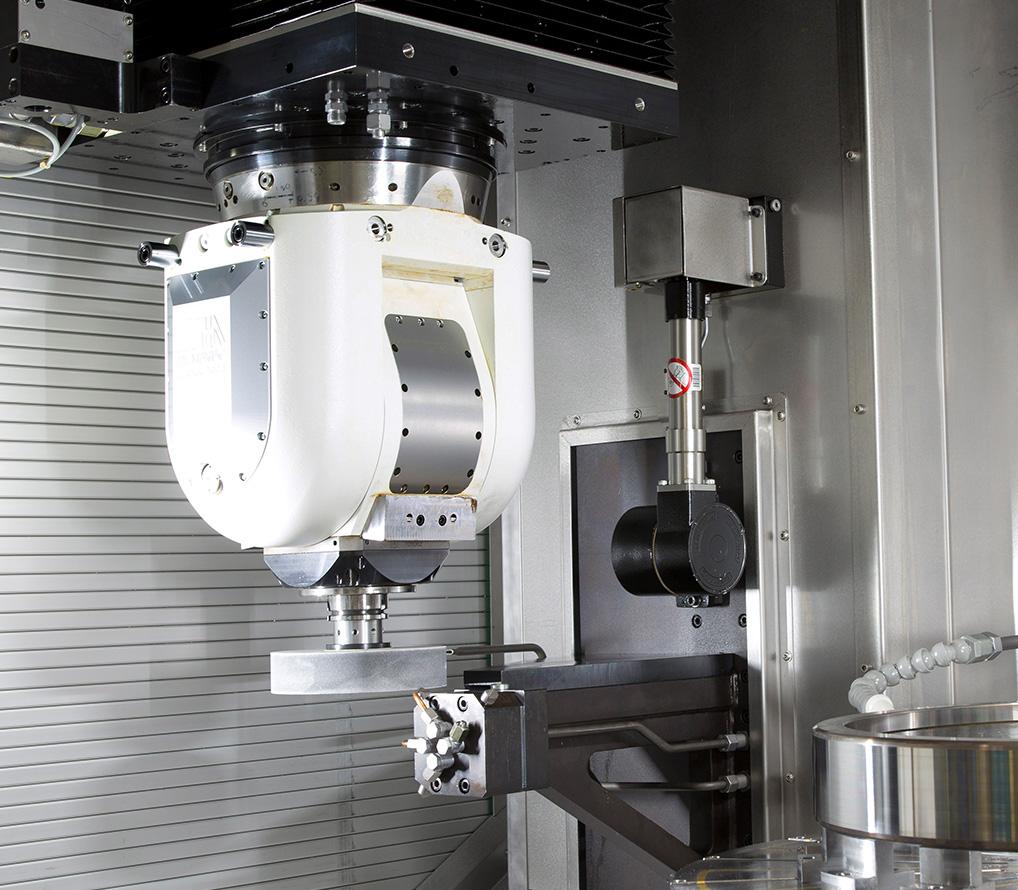

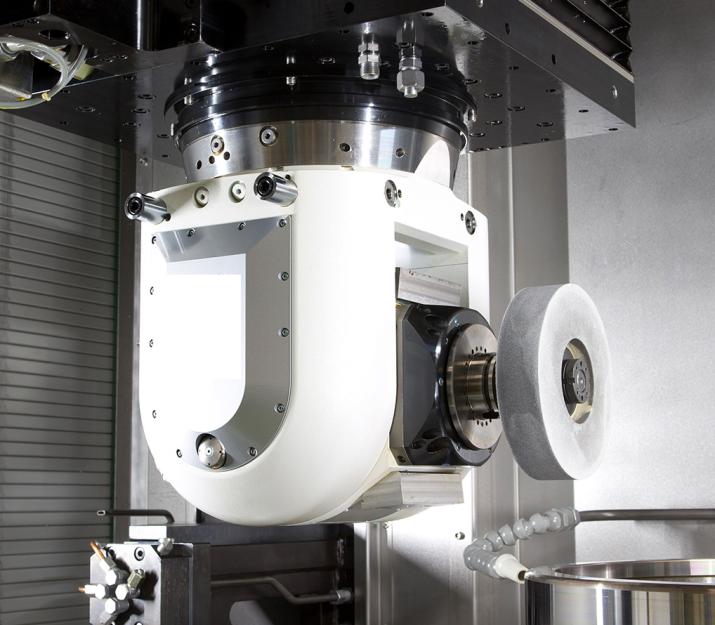

It is a full-fledged hybrid hard turn and fine grinding machine. Thus its capability includes two full-featured machining technologies, where each process is designed to perform a specific type of operation.

You can finish a workpiece using the most suitable process without having to switch machines or even the fixture. This contributes greatly to short cycle-times, saves process steps, and eliminates clamping errors.

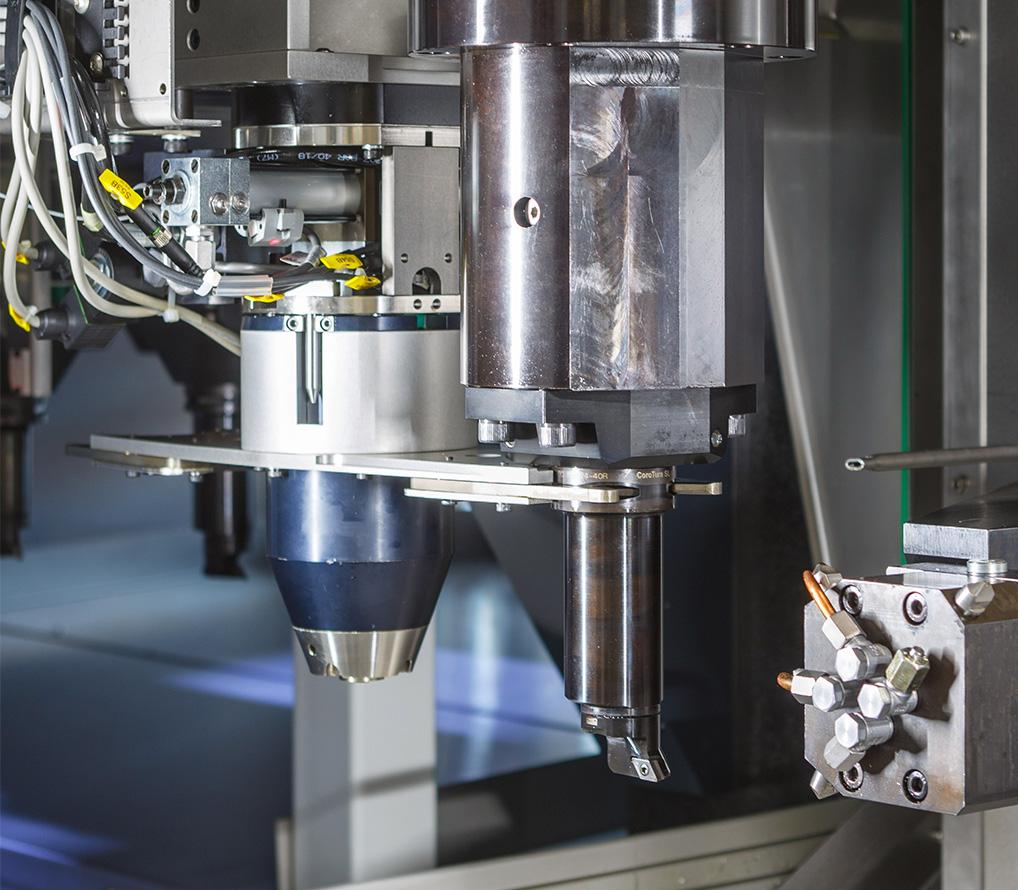

Wear-free hydrostatic main spindle

High precision hydrostatic main spindle with guaranteed runout ≤ 0.000004” (0,1 µm) and high dynamic stiffness.High surface accuracy, and good tool life.

Granite base and main spindle housing

All components critical for precision are mounted on a natural granite base, which is inherently temperature stable and vibration damping. Plus vibration absorbing mounts isolate the granite base from the machine’s metal frame. Corrosion free and free of any stresses.

Wear-free hydrostatic guideways

High precision hydrostatic guideways with 0.00004” (1 µm) positioning and 0.000008” (0,2 µm) repeatability, controlled by linear scales.

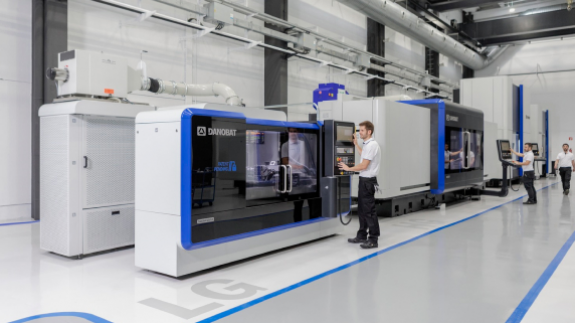

Siemens or Fanuc control

Siemens Sinumerik One or Fanuc 321 CNC control, with 0.0000004” (0,01 µm) resolution.

Thermal stability

Heat sources and vibrating elements are placed outside the machining area, ensuring excellent thermal stability during series production.

| MTG Vertical | ||

|---|---|---|

| Max. turning diameter | mm | 1000 |

| Max. turning height | mm | 300 |

| Spindle speed | rpm | 800 |

| CNC control | - | Siemens Sinumerik One |

| Floor space | m2 | 18,3 |

| Positioning | - | RAM in the Z axis by means of a Hirth coupling |

| MTG Vertical | ||

|---|---|---|

| Max. turning diameter | in | 39.4 |

| Max. turning height | in | 11.8 |

| Spindle speed | rpm | 800 |

| CNC control | - | Siemens Sinumerik One |

| Floor space | sqft | 197 |

| Positioning | - | RAM in the Z axis by means of a Hirth coupling |

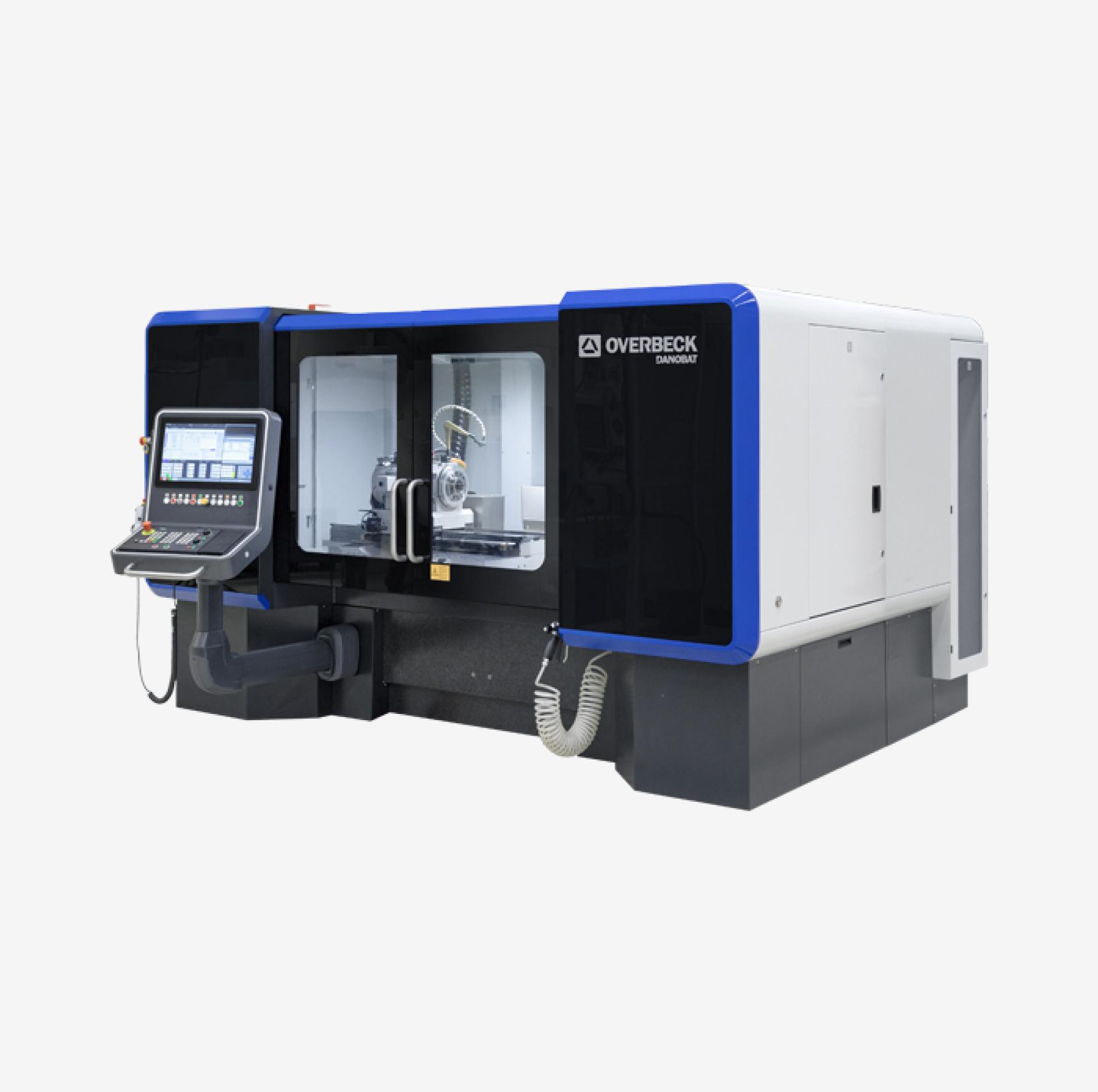

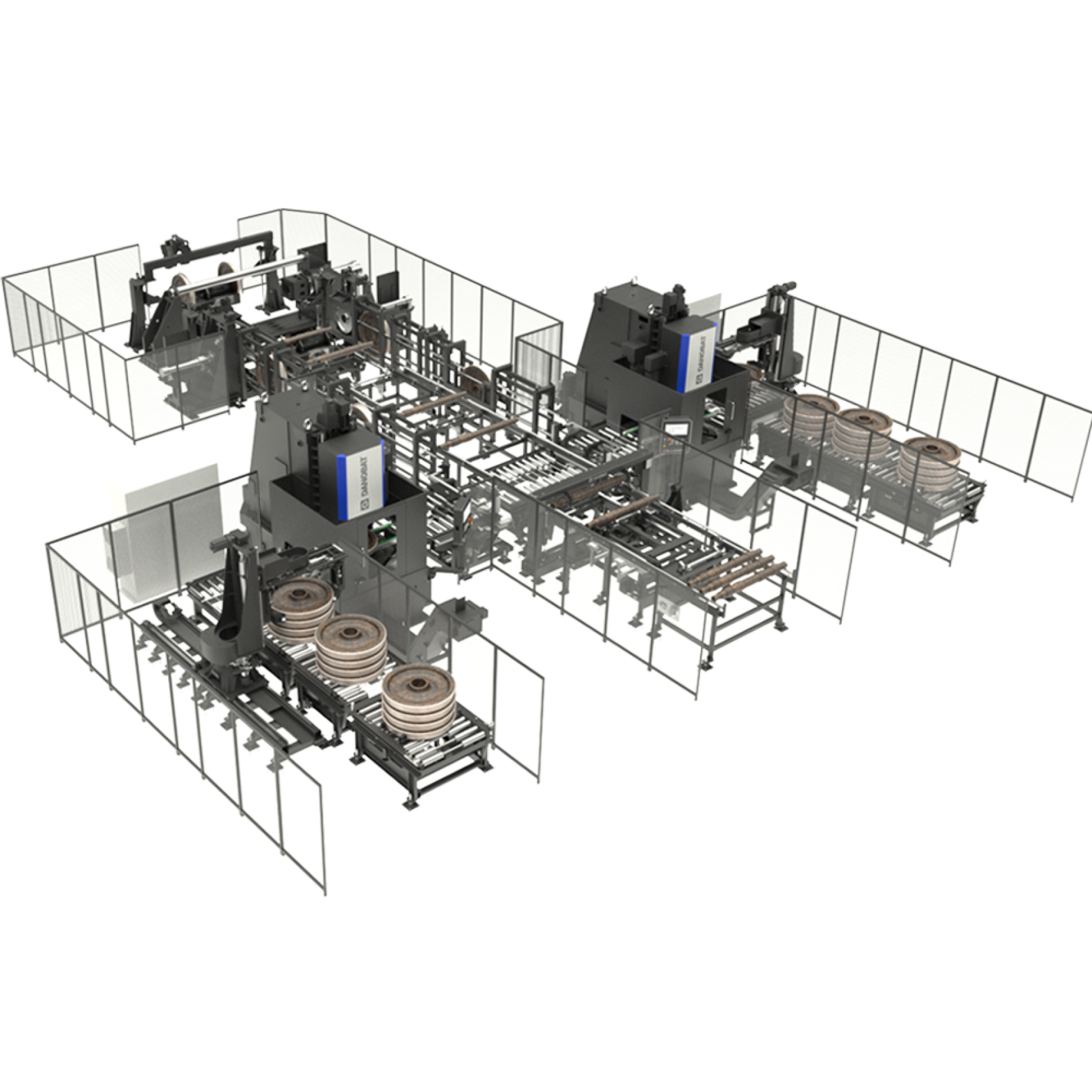

Inner & outer ring

- Customized maintenance plans based on your production needs: ball bar test, verification of geometry and much more

- Retrofitting: We overhaul the complete machine or specific modules, such as the workhead and guiding systems

- Engineering and process development: Select the proper clamping and tooling solution for your new part