Email us

Reliable and cost-effective sub-micron machining solutions for wind industry

The wind industry is under enormous pressure to reduce cost per HPh. They need to improve turbine designs, raise performance, and increase reliability – all while reducing maintenance costs.

Wind turbine operators must ensure that their assets remain operational for as long as possible. Turbines often operate under tough conditions – offshore, in cold climates, or in remote locations – which can limit their performance and reliability. The high cost of repairs and long lead times for replacement parts can make energy generation uncompetitive. Anything that prevents a service trip can boost return on investment and reduce the cost of energy.

Generators, gearboxes, and bearing manufacturers are vital players to design cost-effective solutions for the future of this industry. Their precision components must withstand big loads, stresses, and vibrations and operate under punishing environmental conditions. Quality machining is key to reducing fatigue, improving retention of lubrication, and increasing life.

Download this video if you want to know:

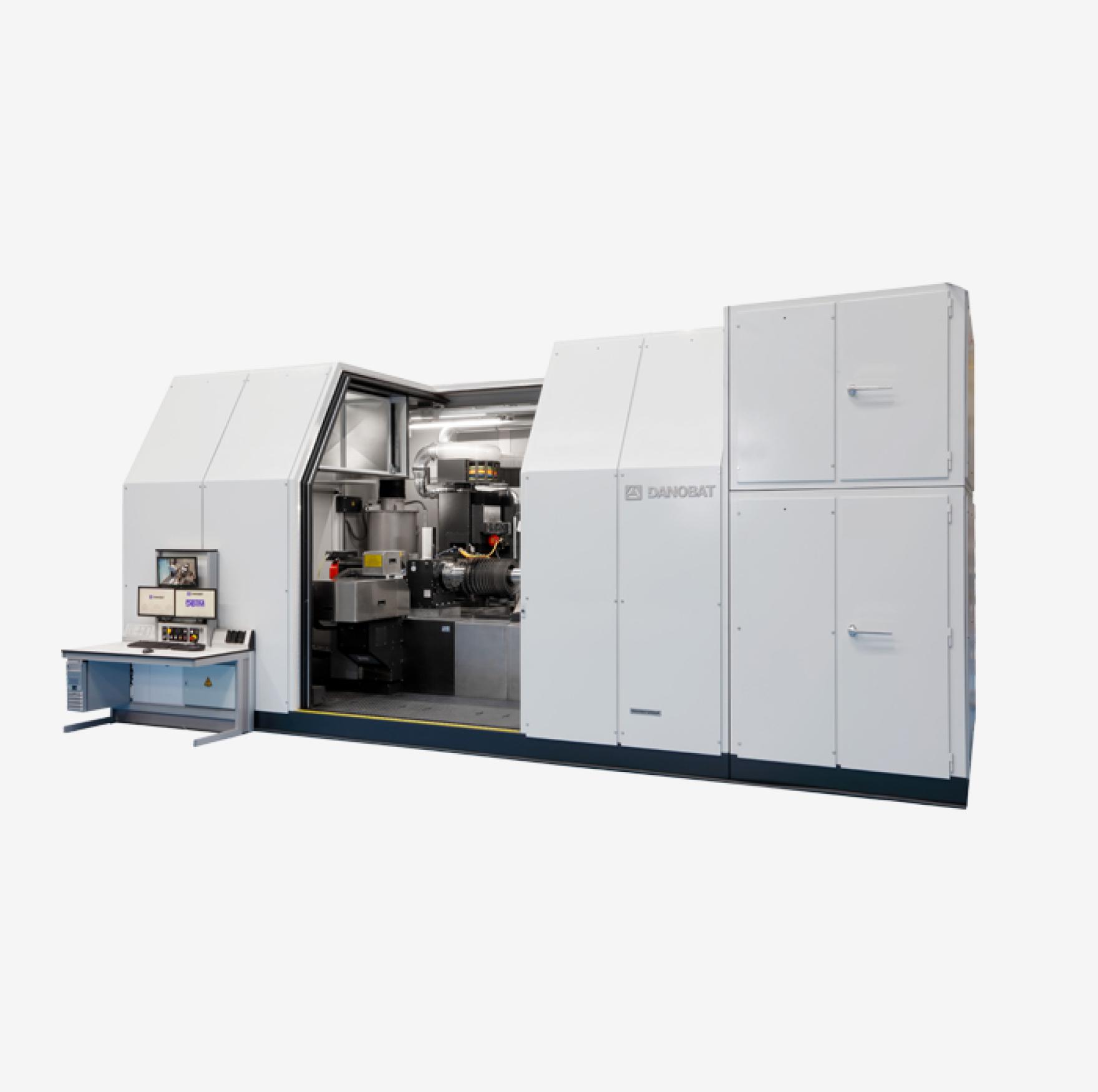

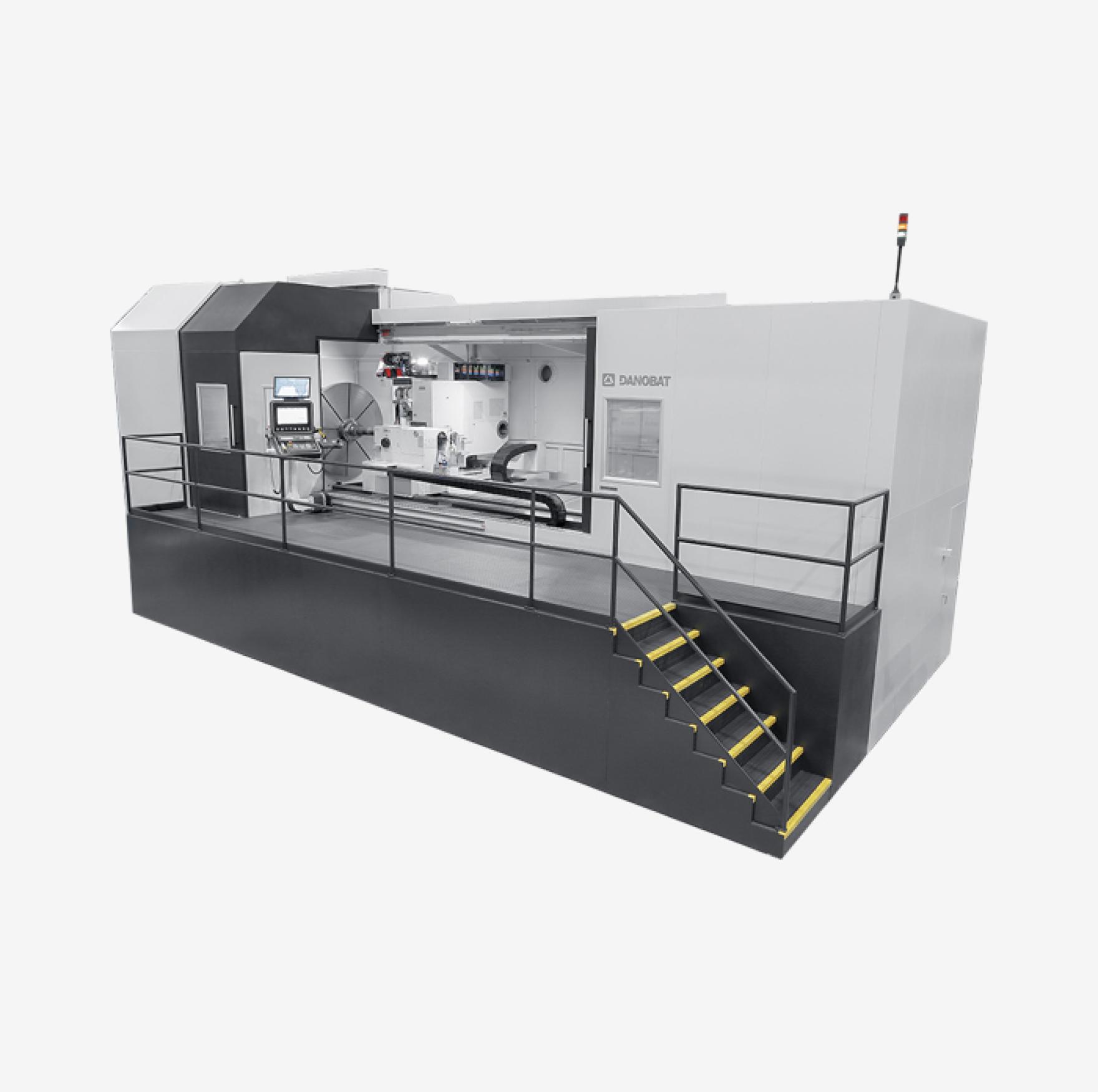

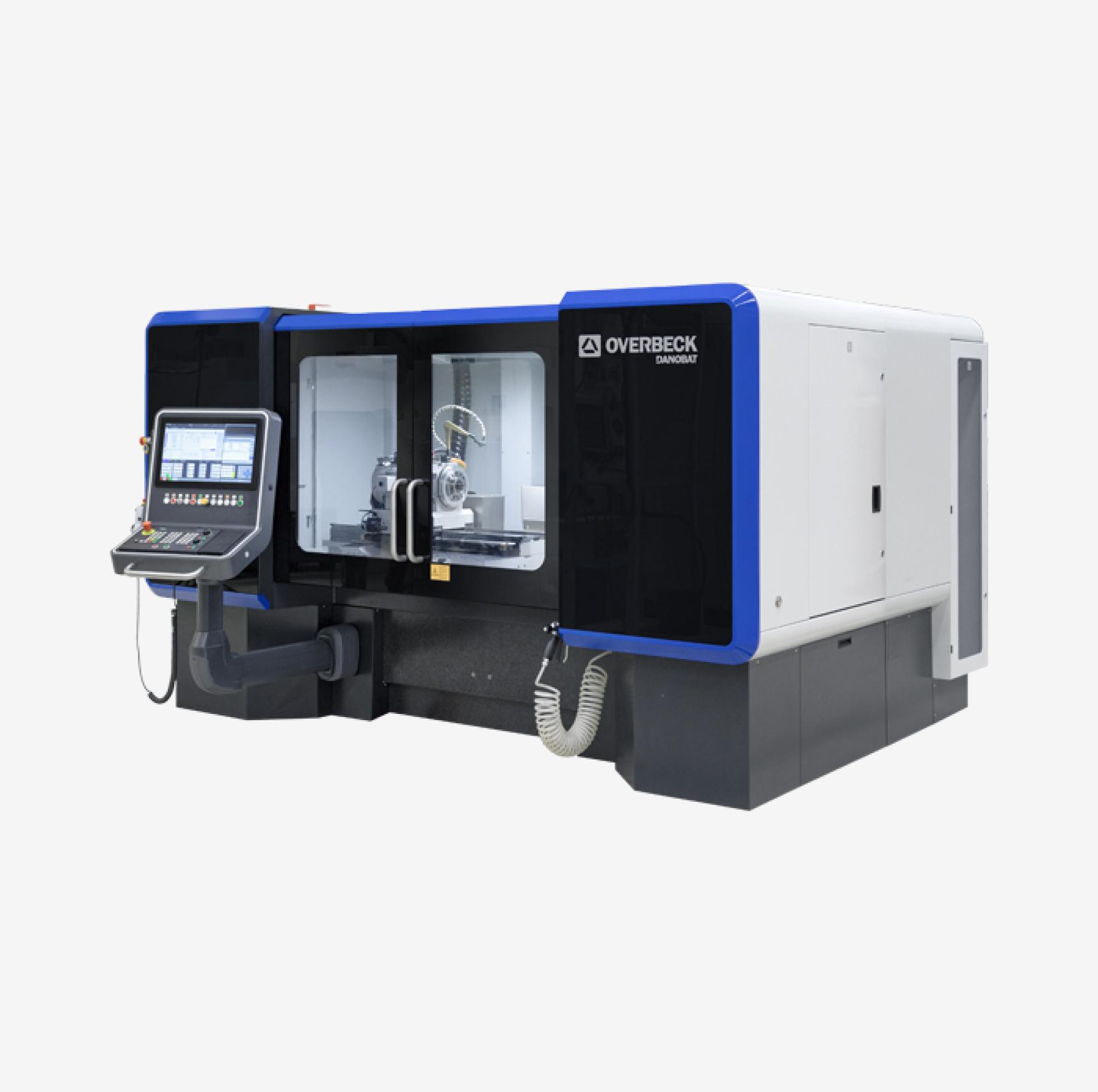

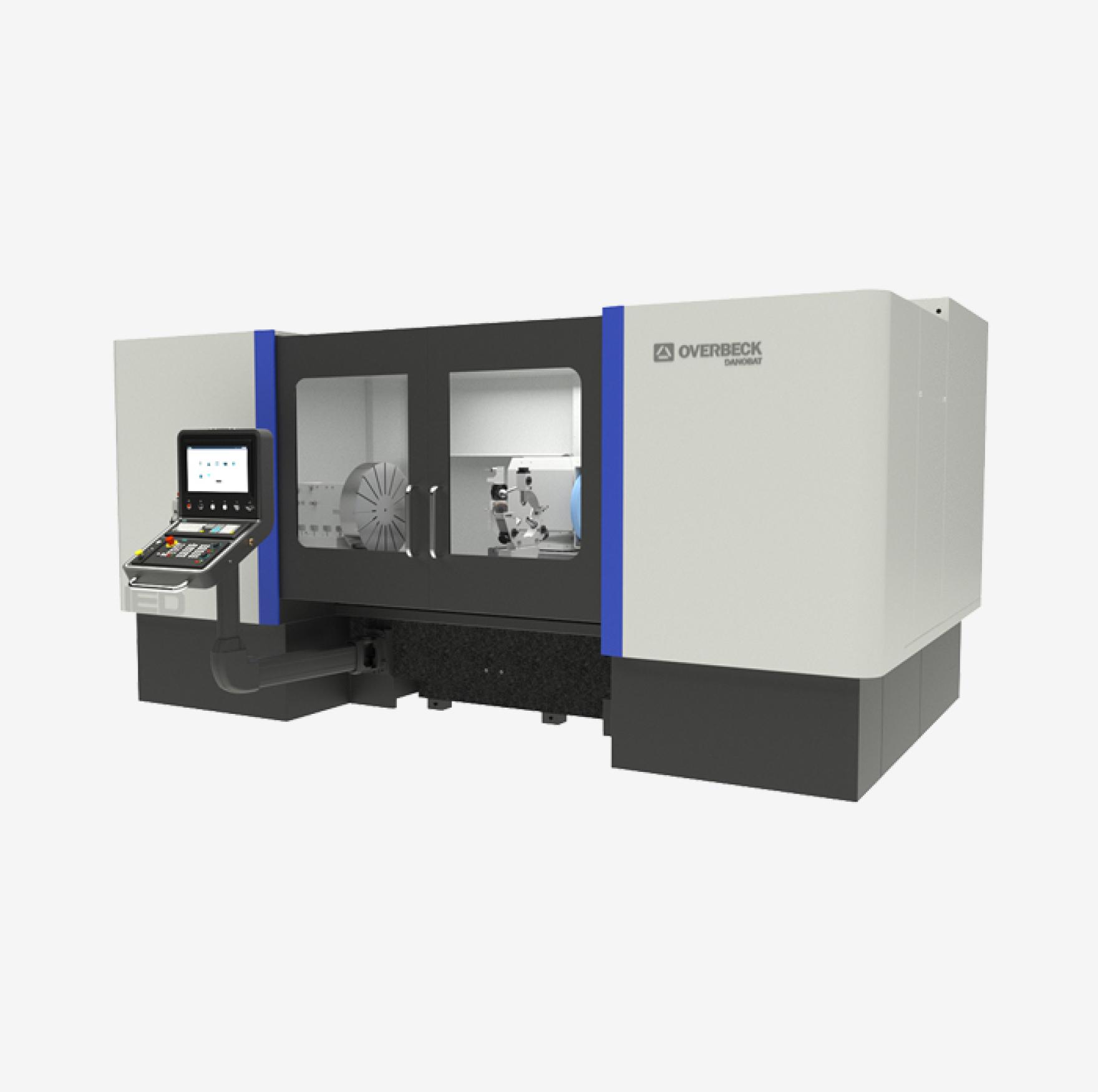

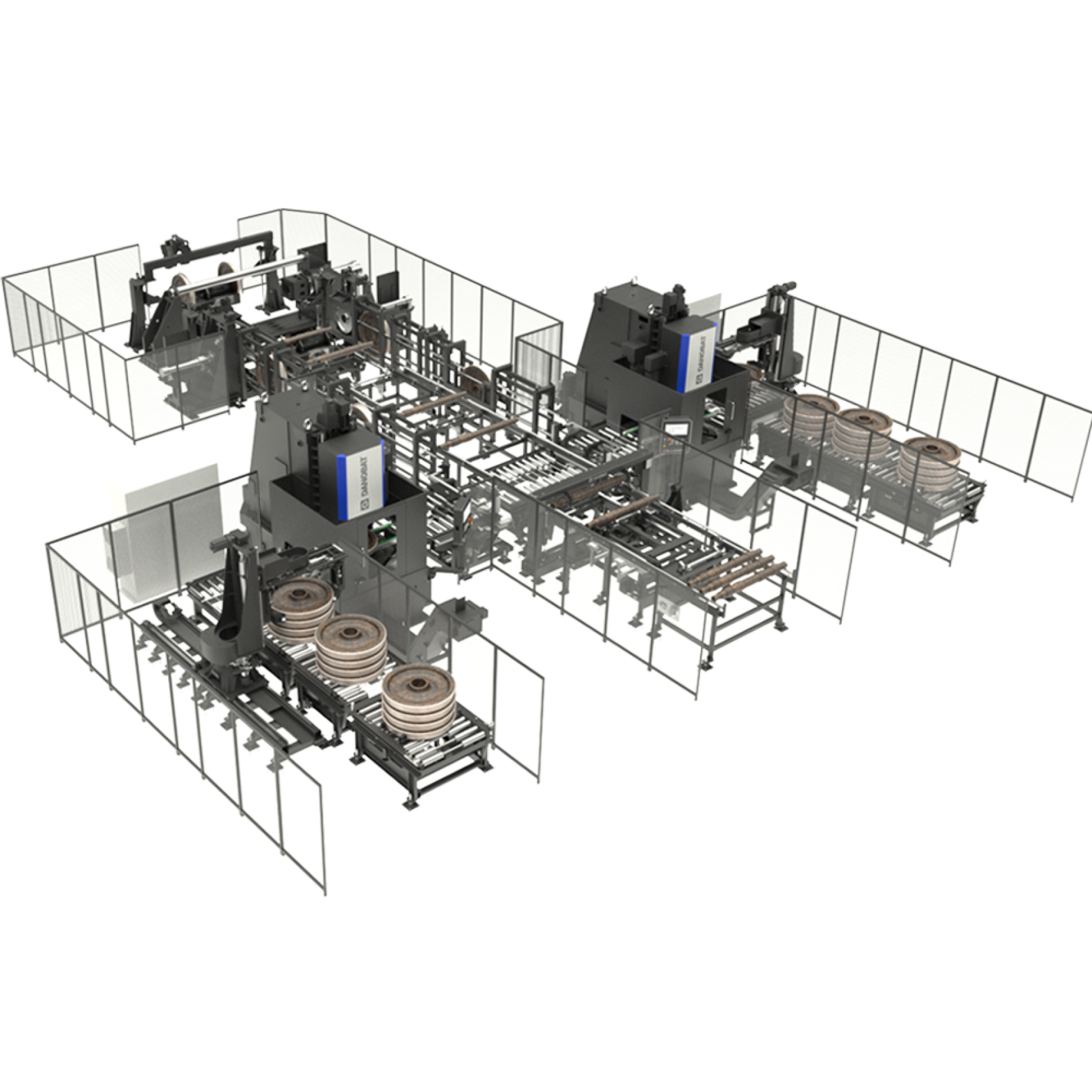

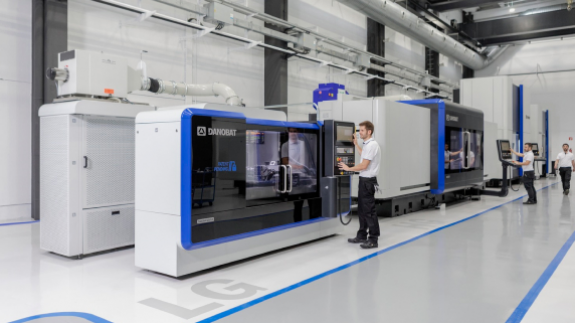

* How to increase 20% productivity in transmission shaft grinding

* How to work in 24/7 environments with maximum availability

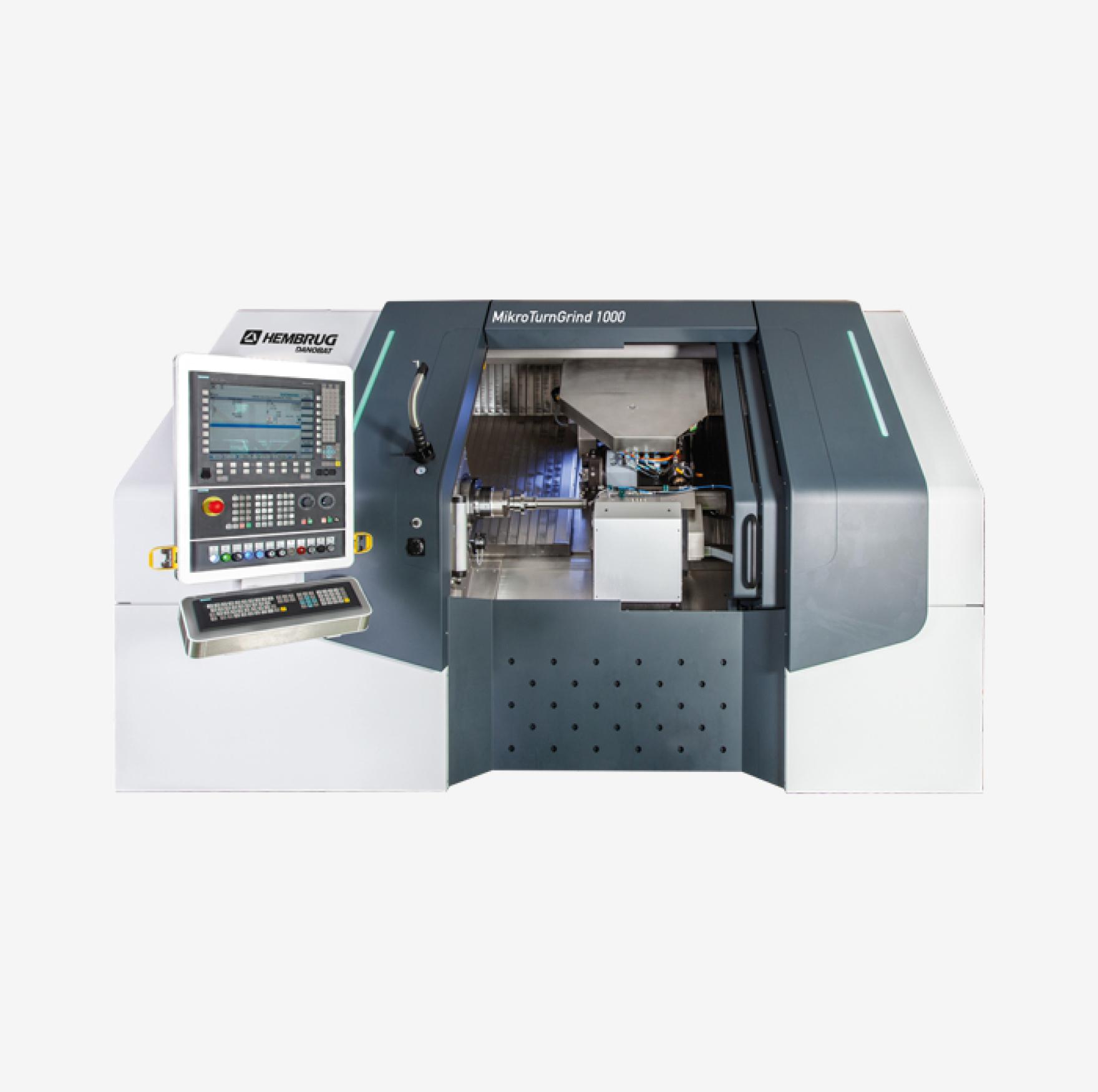

* How to hard turn cylindrical, tapered, or spherical rollers in a single set-up

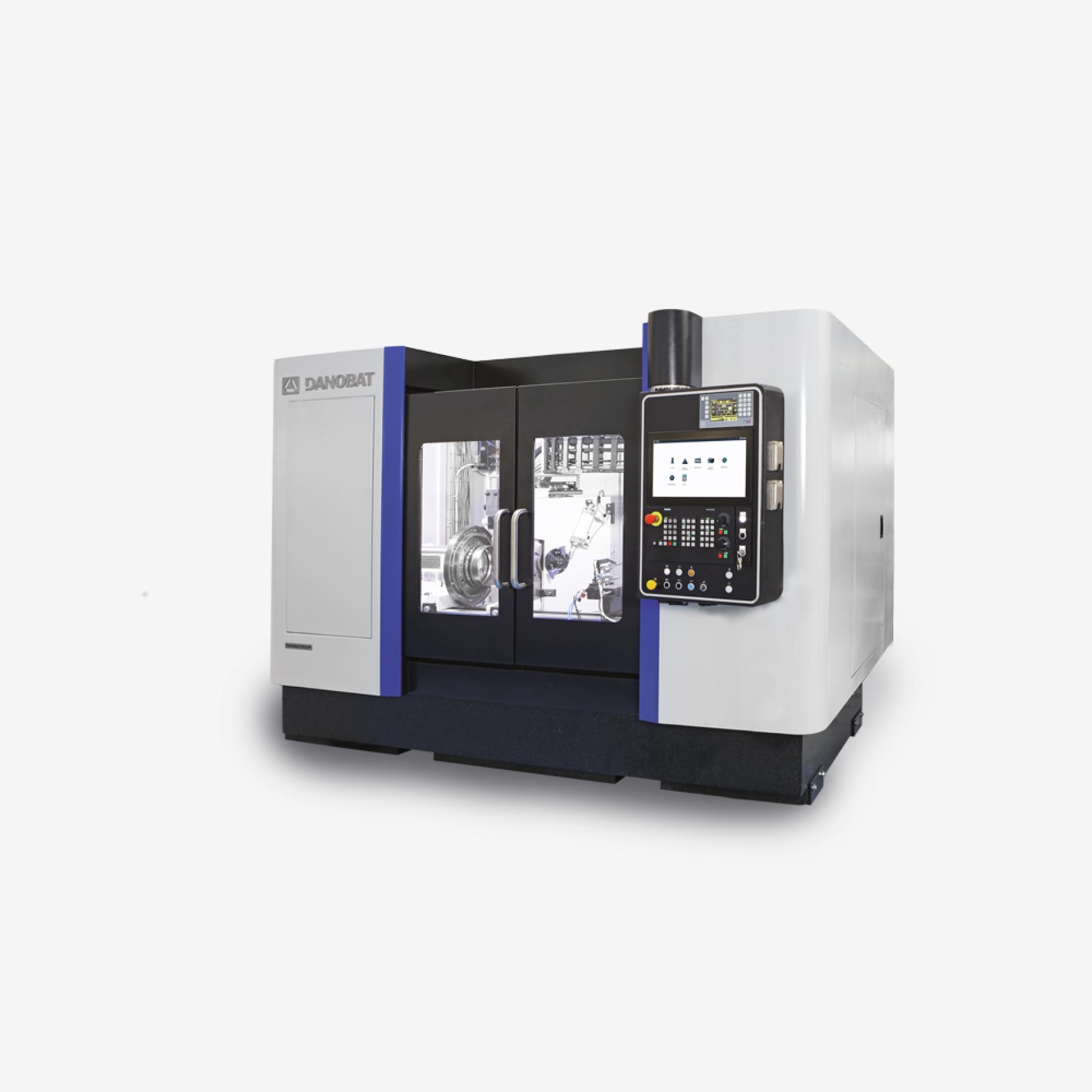

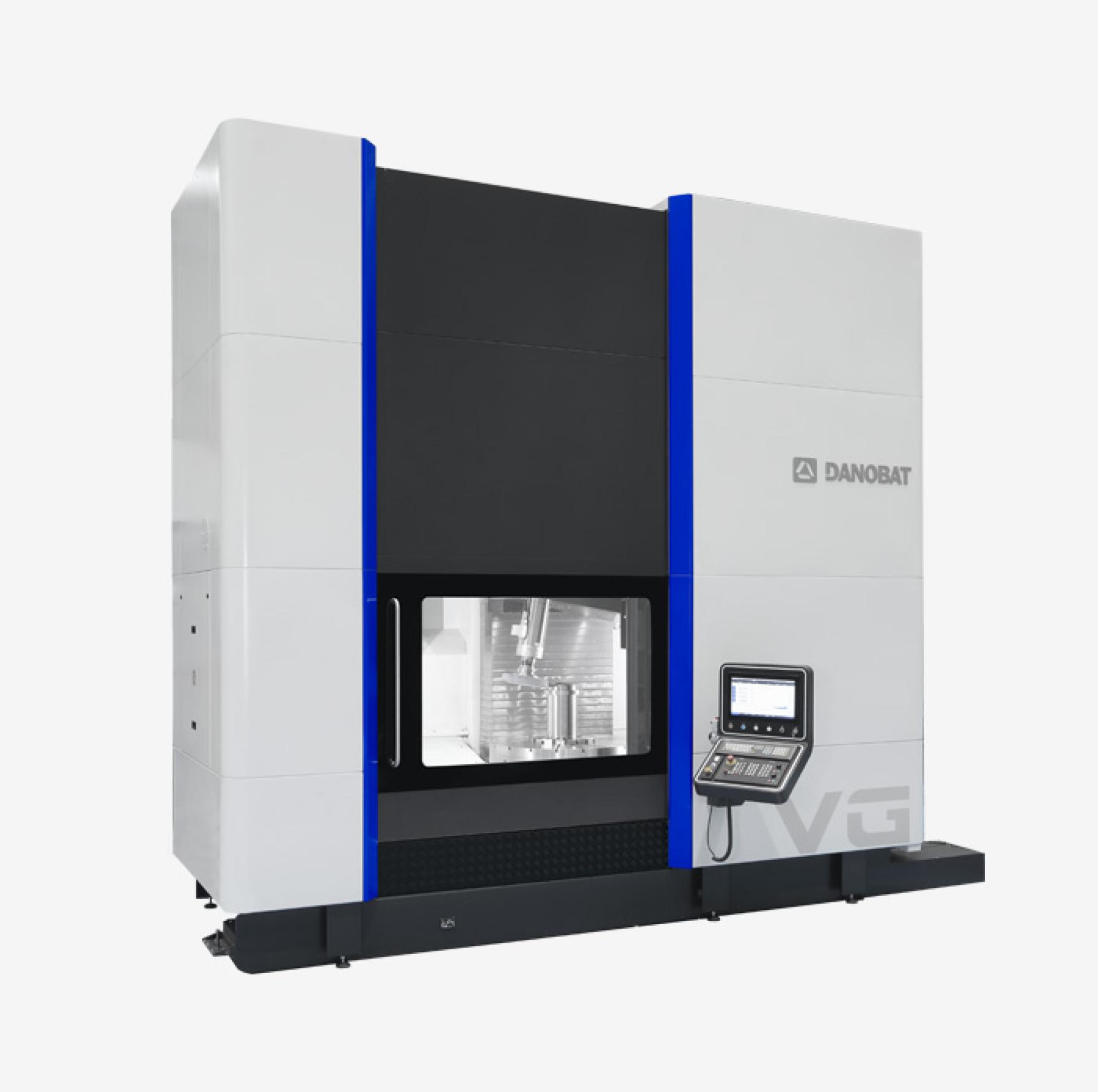

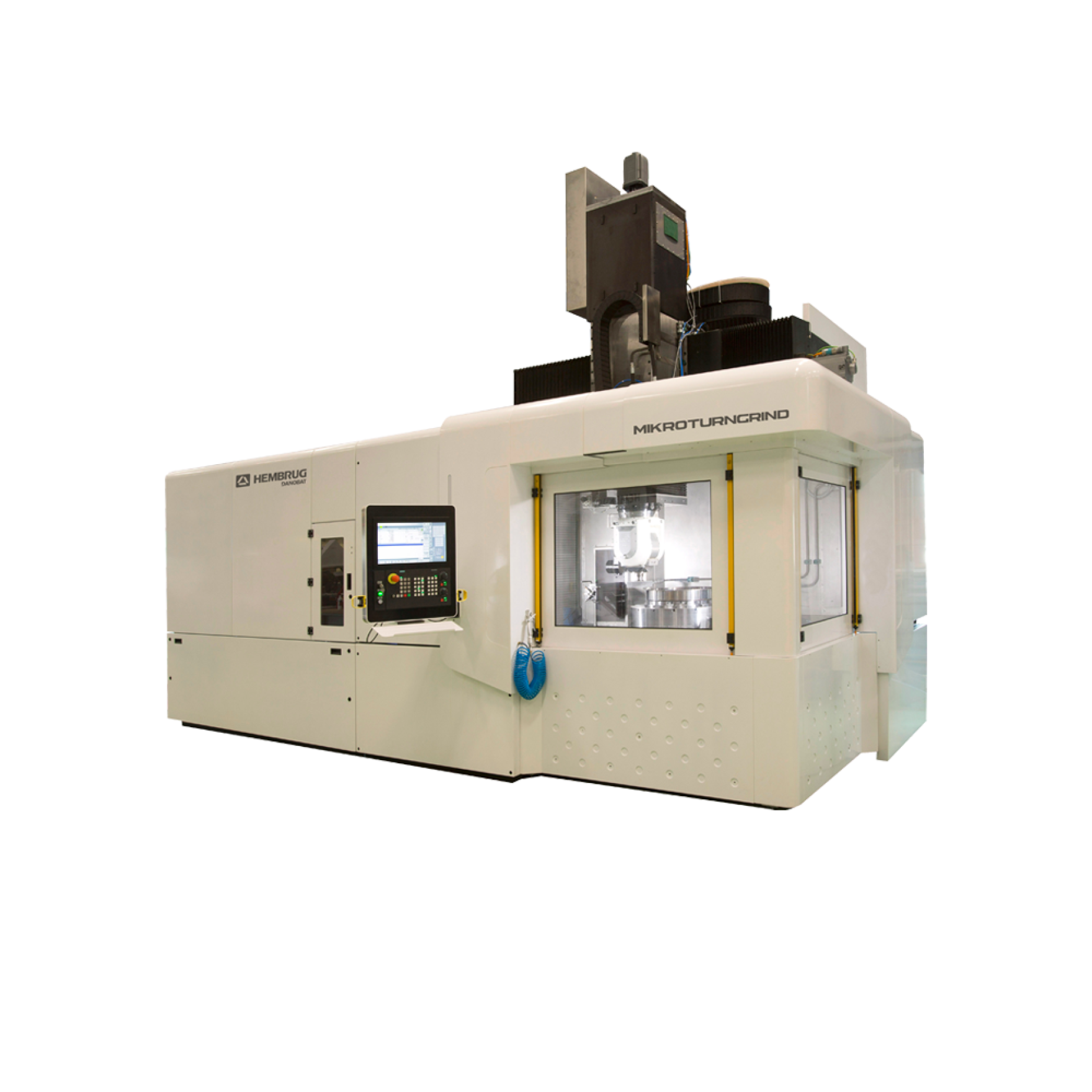

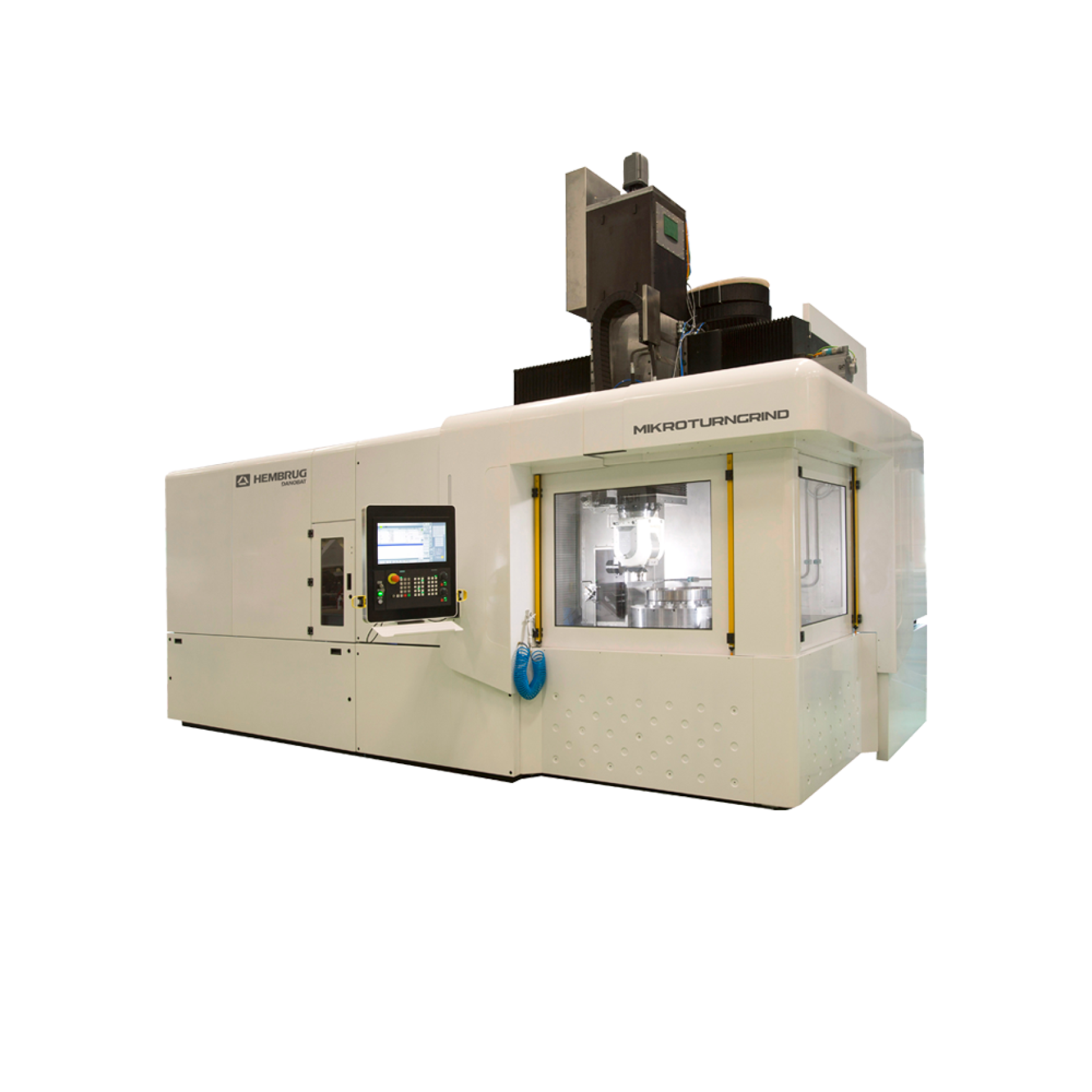

* How to grind the bearing rings in a very reliable and precise vertical grinding machine