Email us

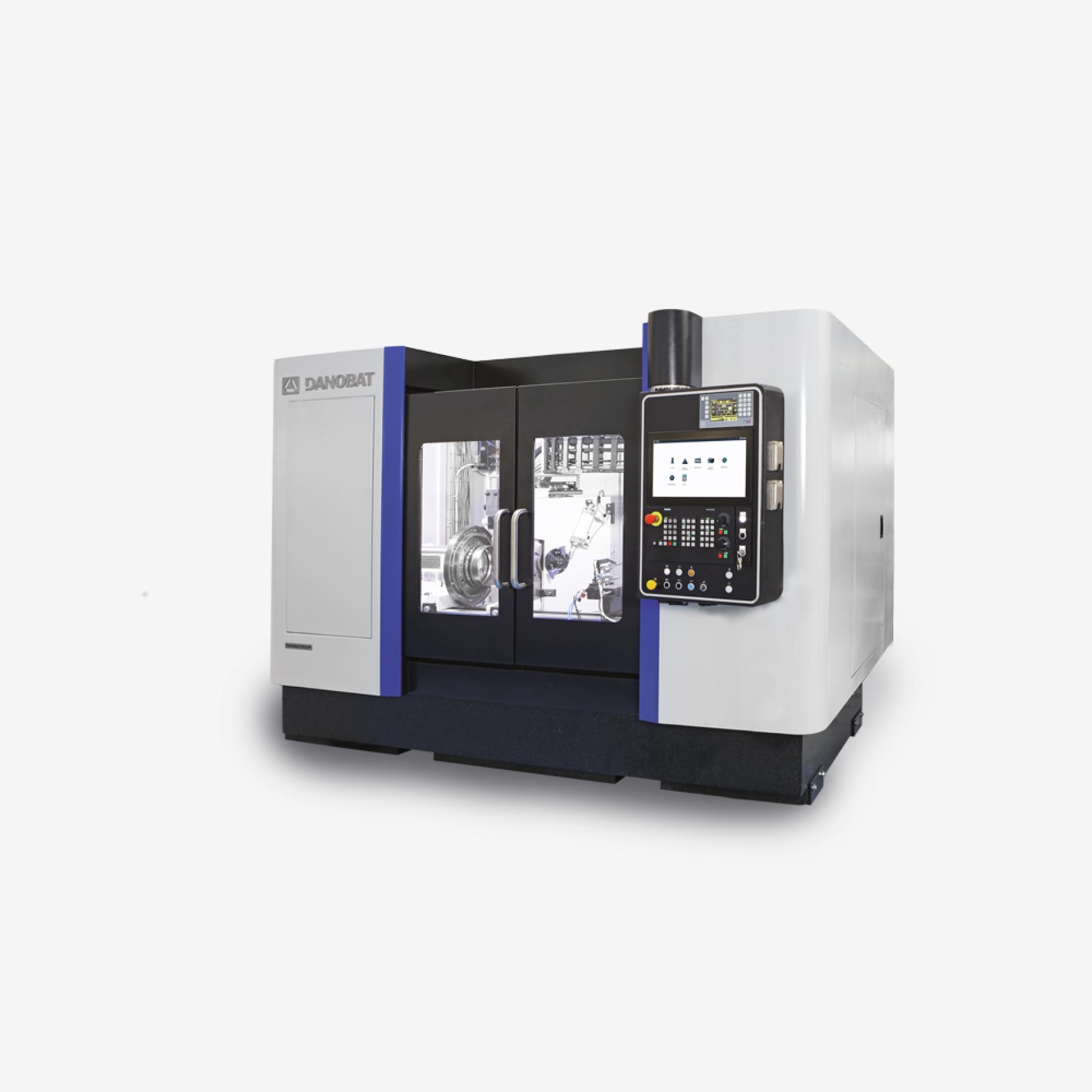

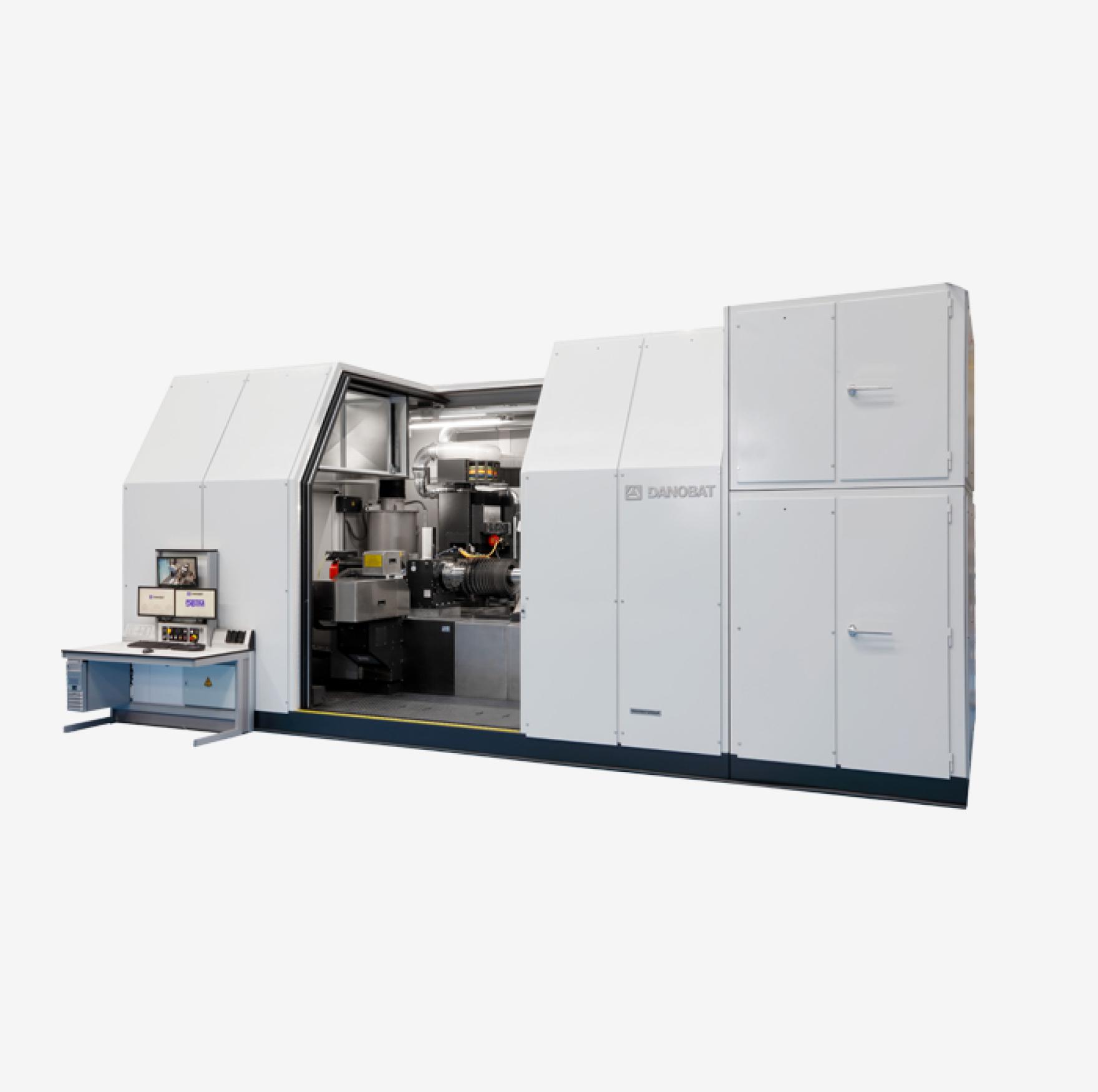

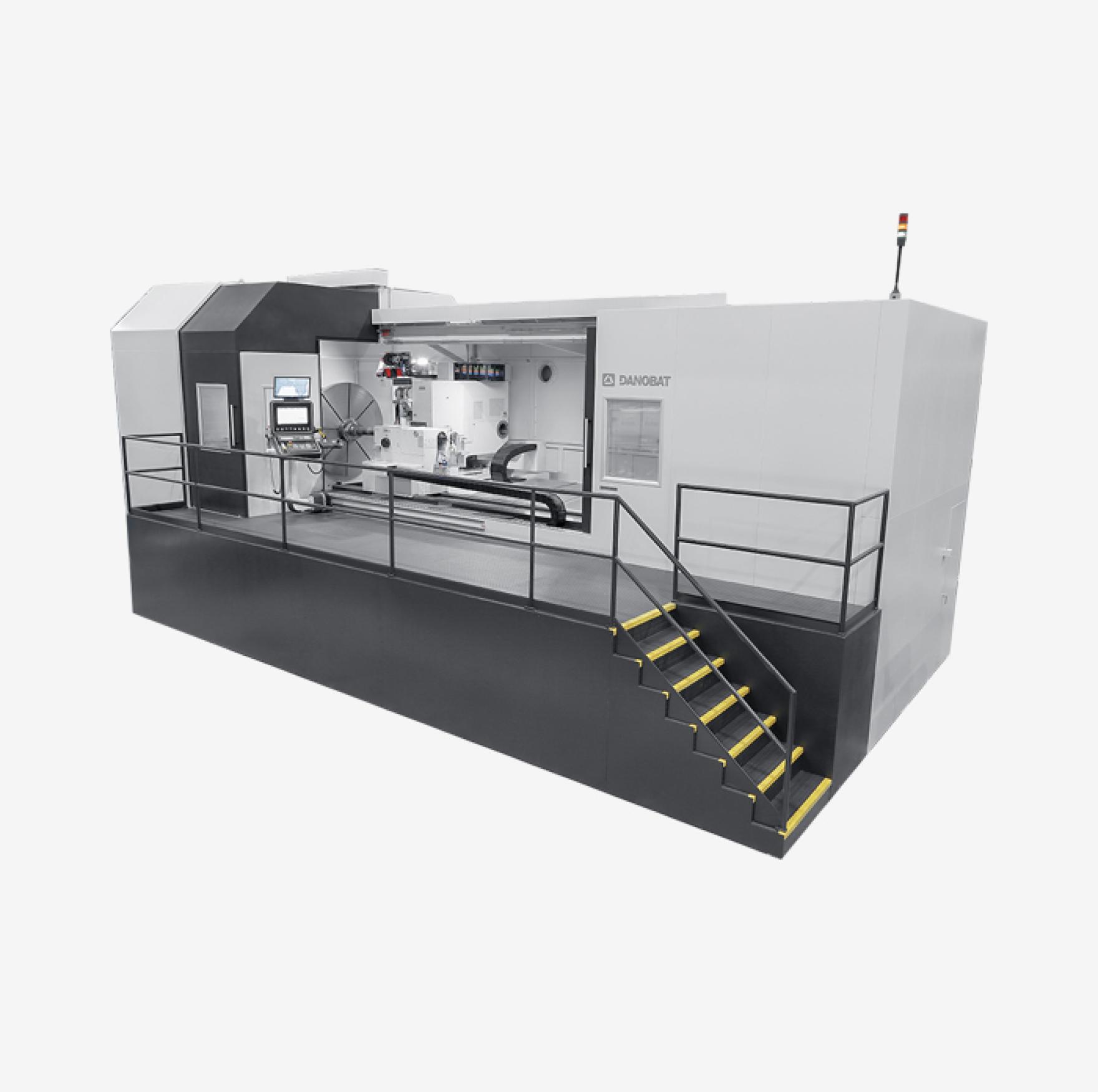

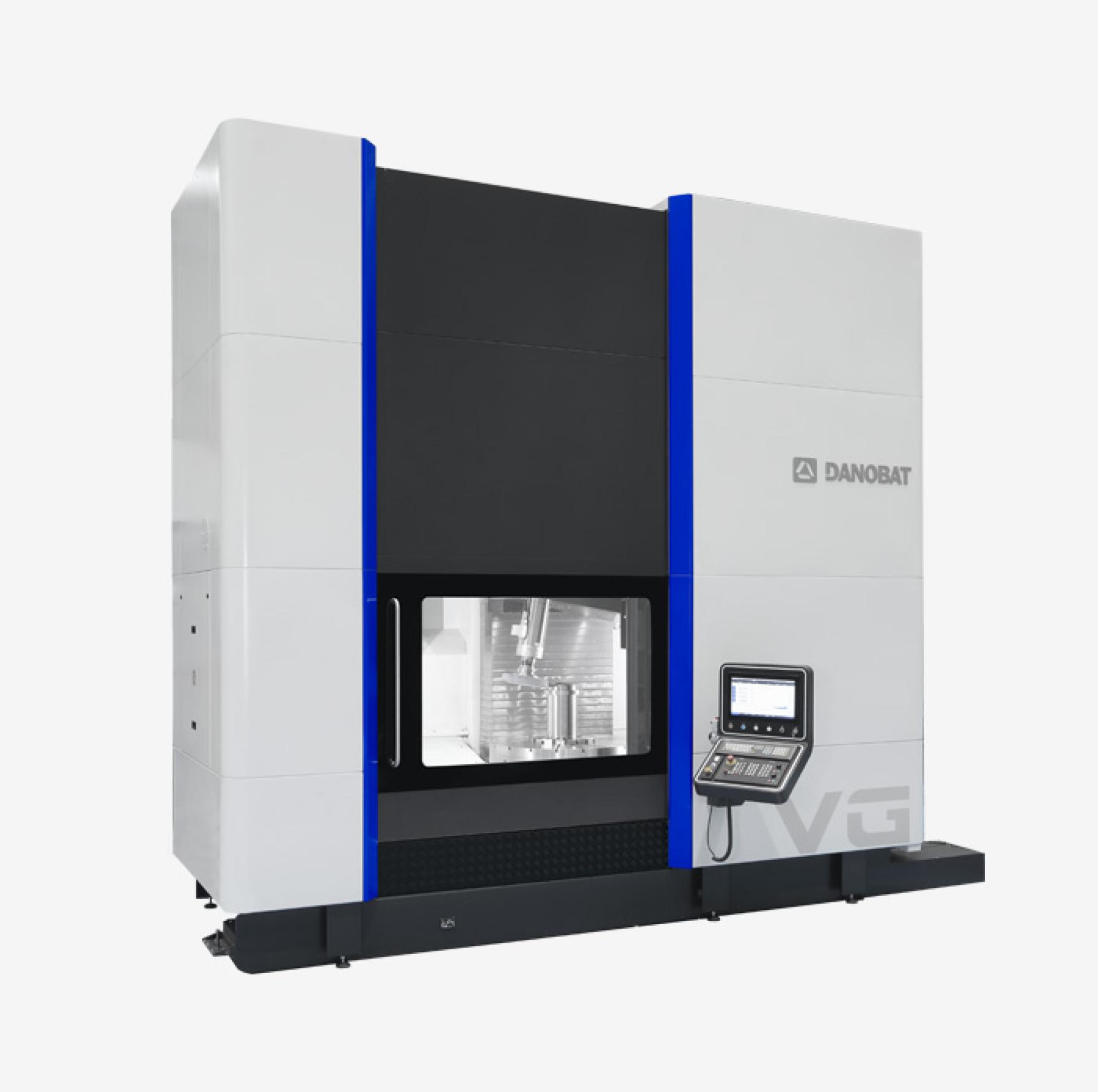

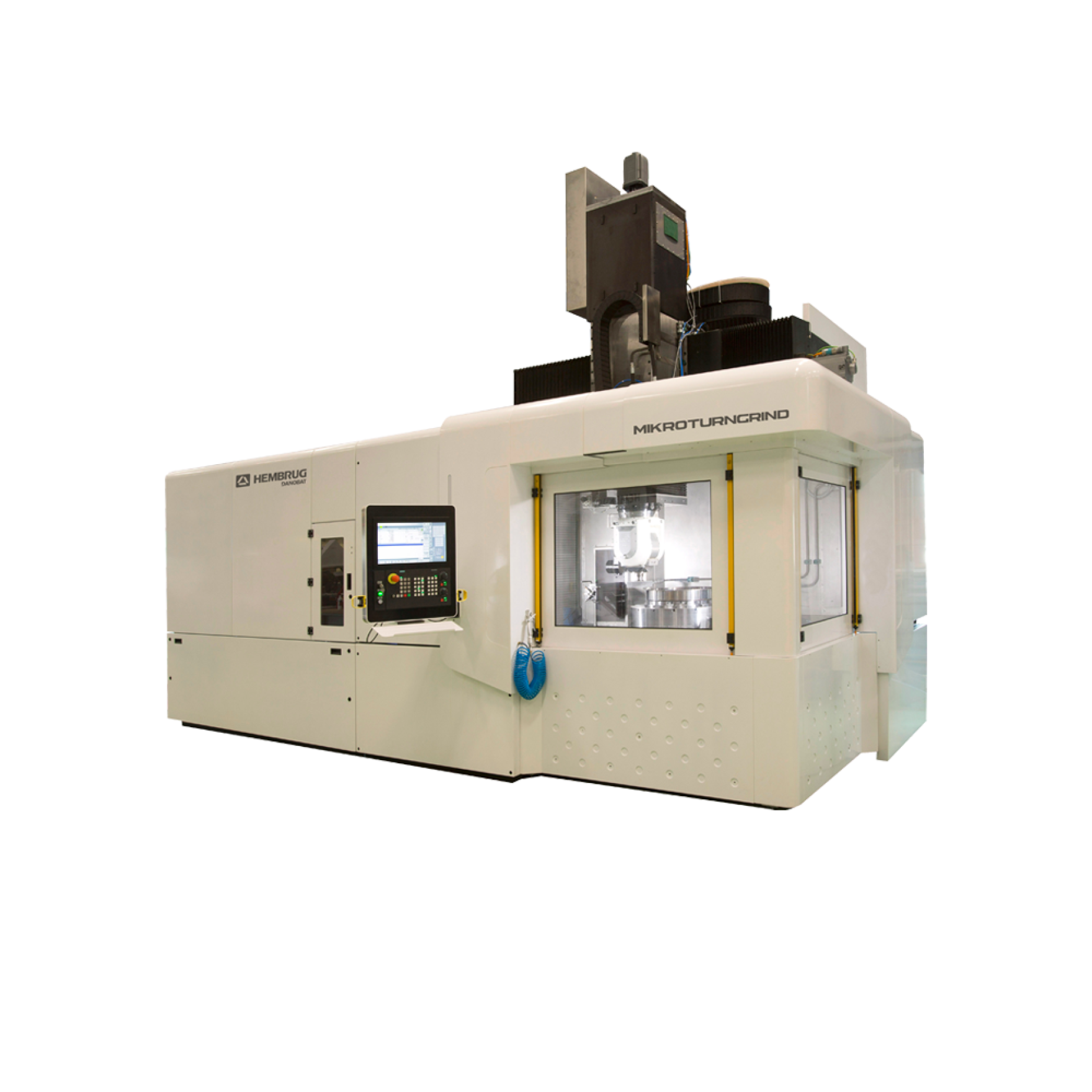

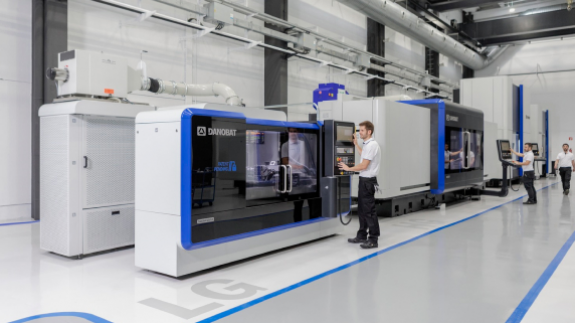

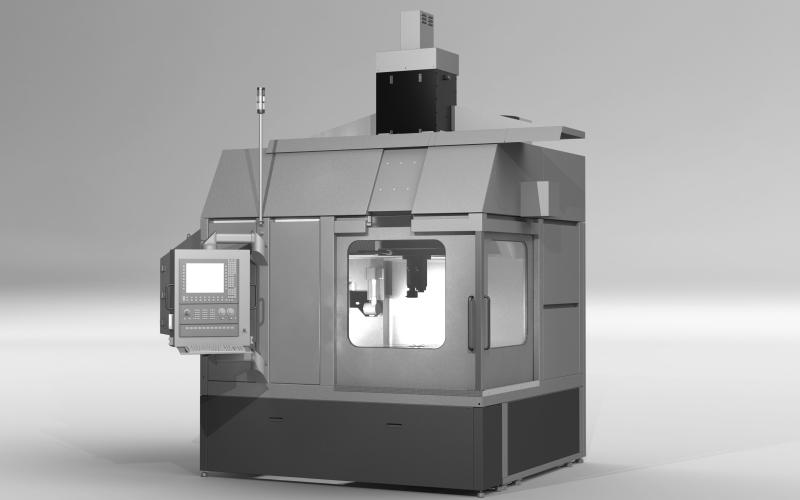

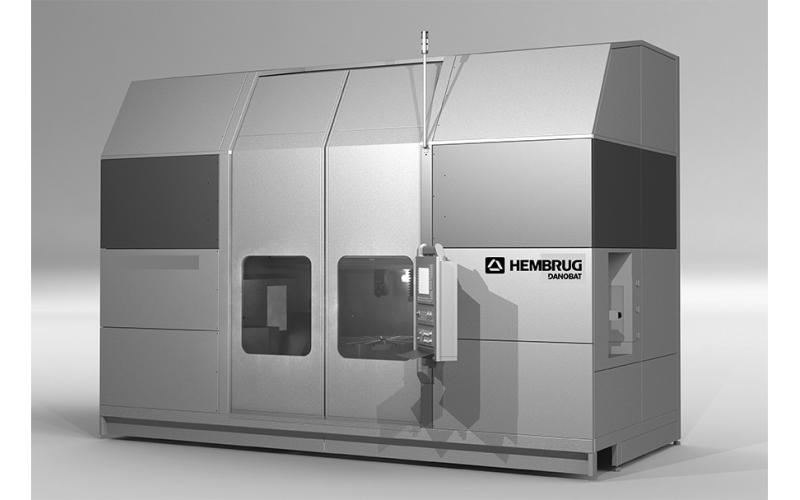

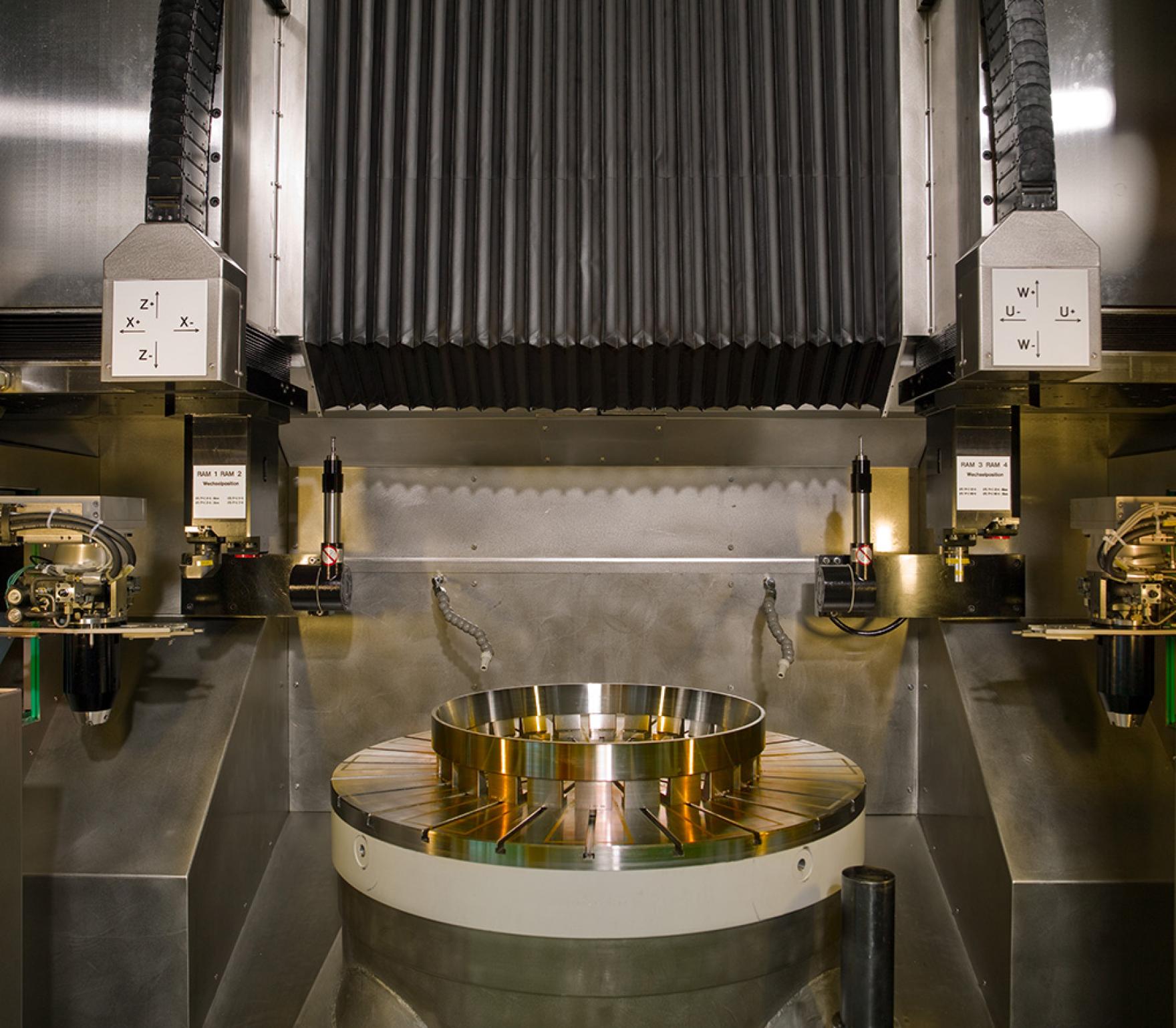

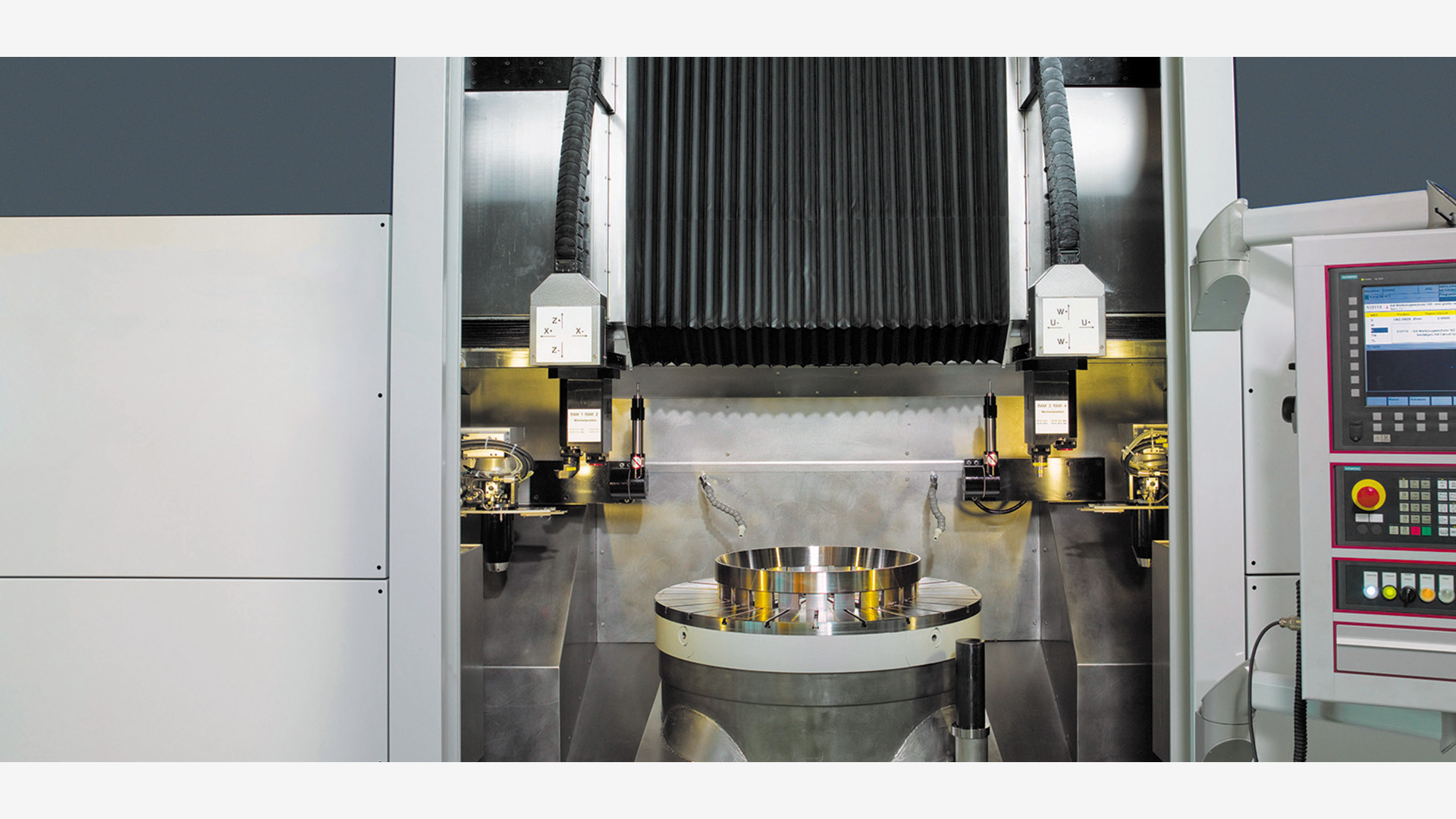

HIGH PRECISION VERTICAL HARD TURNING MACHINE

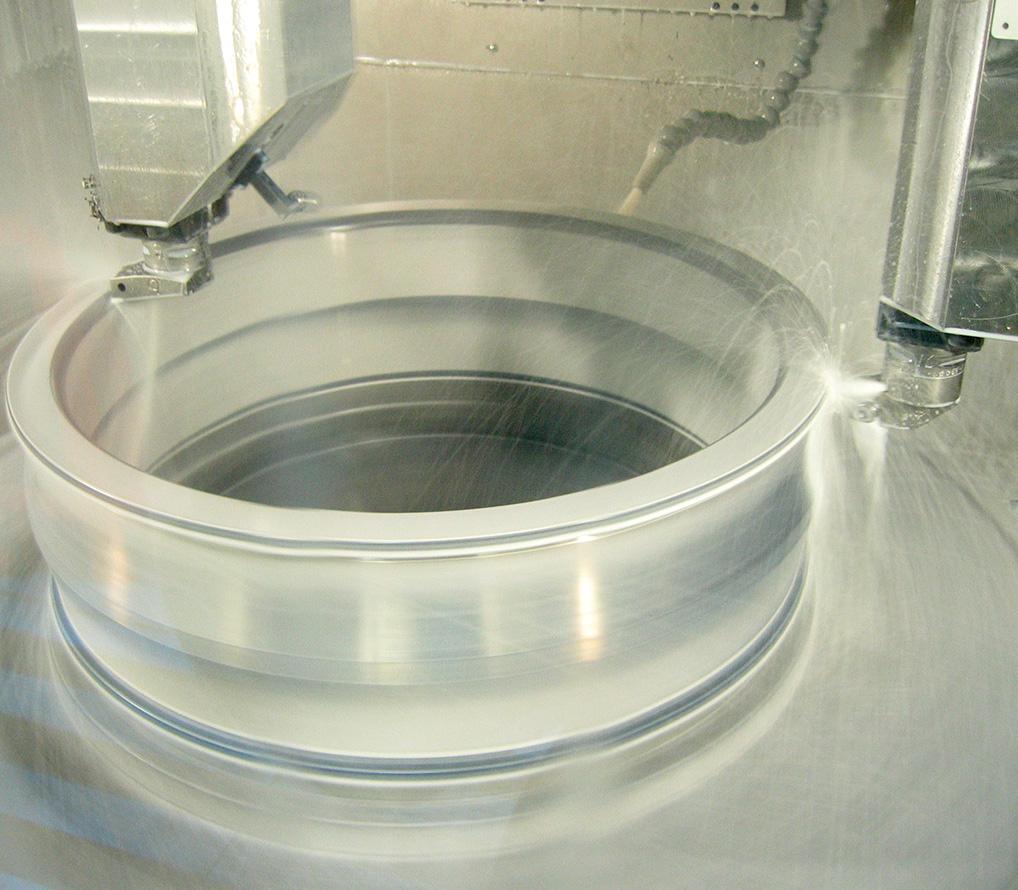

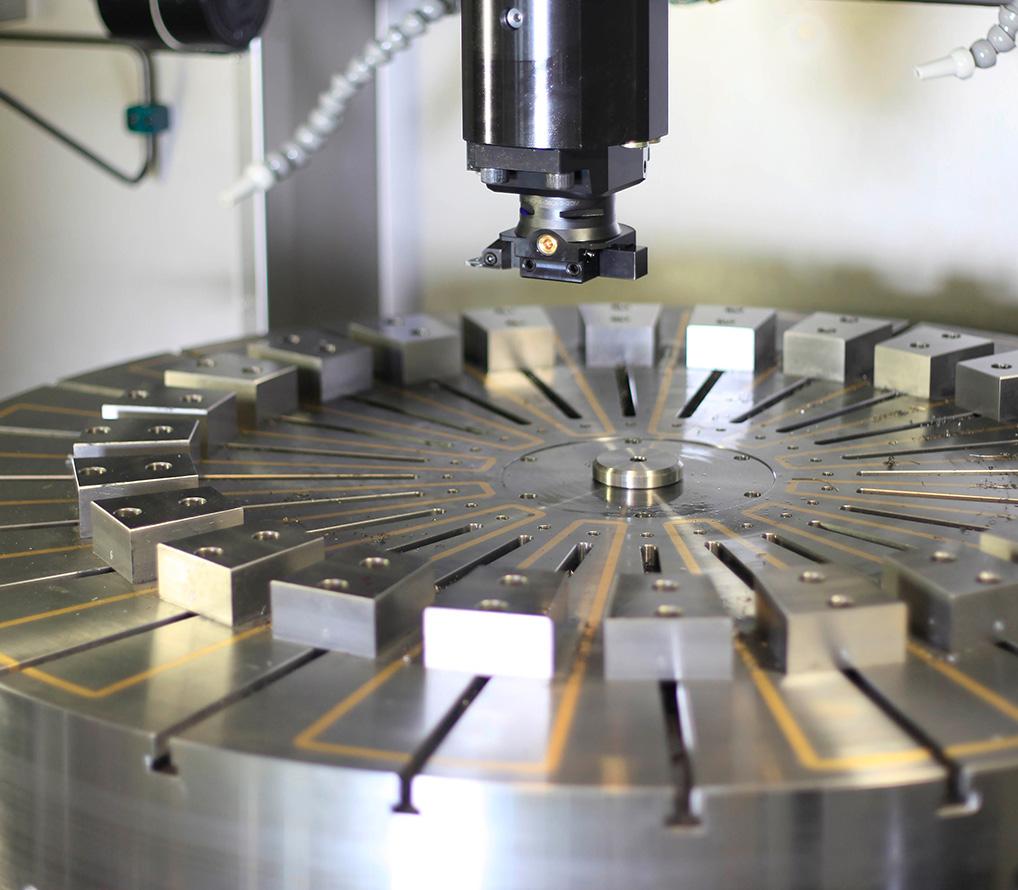

High precision, fully hydrostatic, vertical hard turning machines for large workpieces up to 59” (1500 mm) in diameter and 4400 lb (2000 kg) in weight.

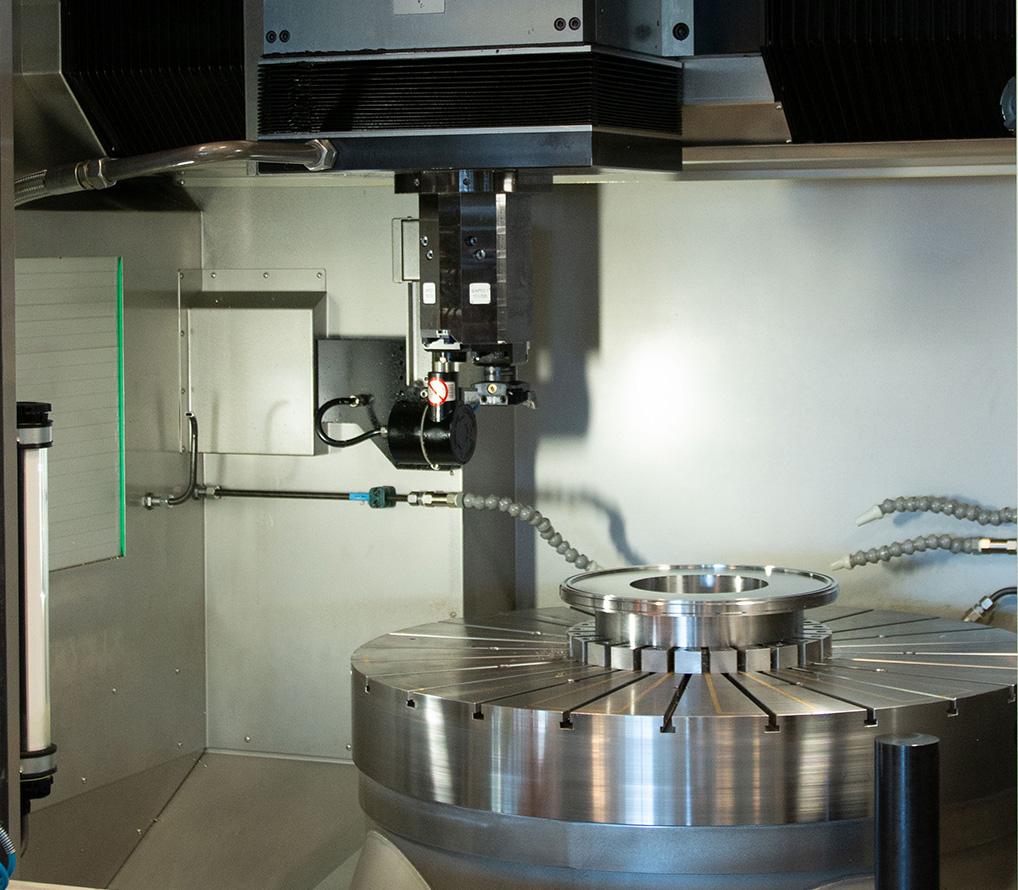

- The Mikroturn® V2, covers parts up to 30" (1000 mm) in diameter and 4400 lb (2000 kg) in weight

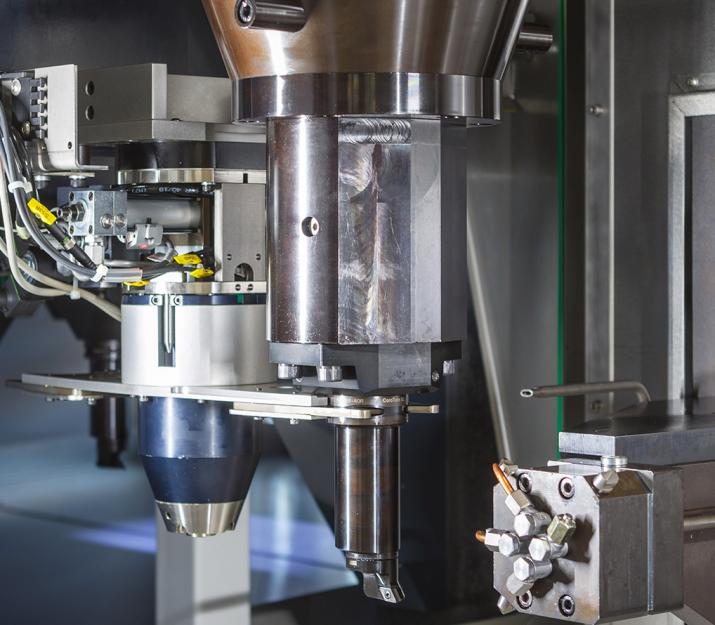

- The Mikroturn® V4 machines OD and ID simultaneously, greatly contributing to cycle time savings of up to 40%

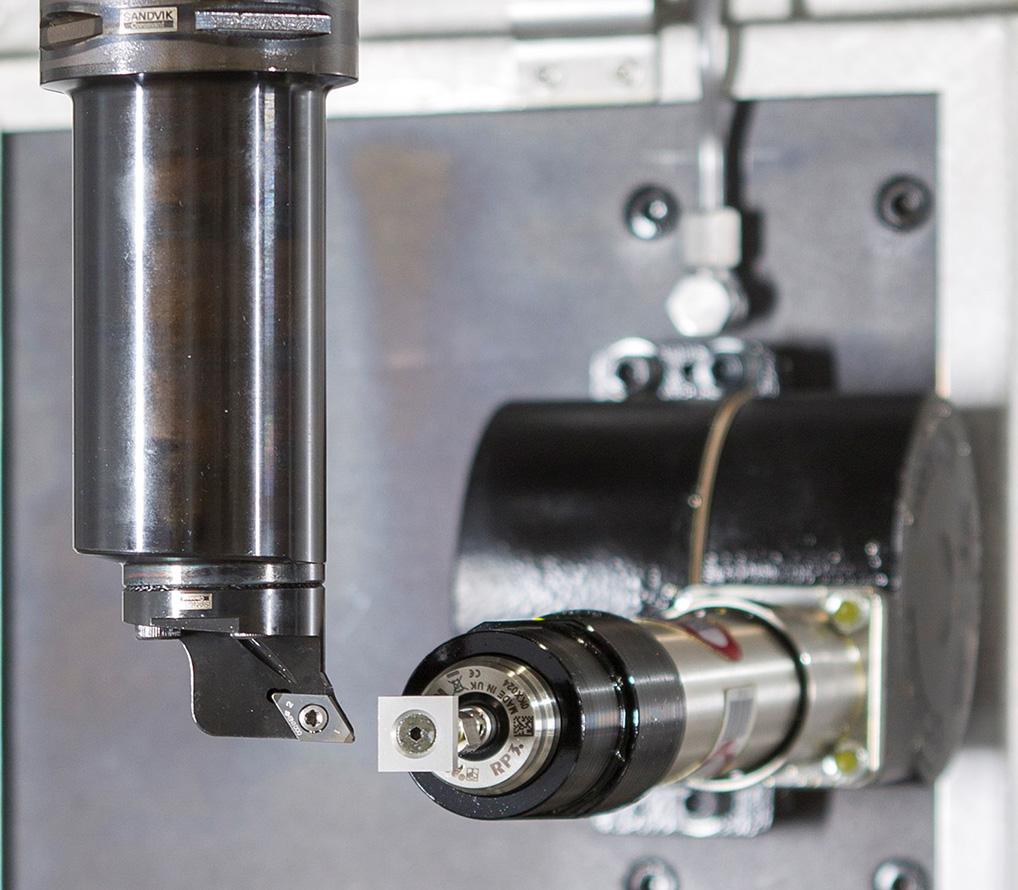

Wear-free hydrostatic main spindle

High precision hydrostatic main spindle with guaranteed run-out ≤ 0.000004” (0,1 µm) and high dynamic stiffness.

High dynamic stiffness, high surface accuracy, and good tool life.

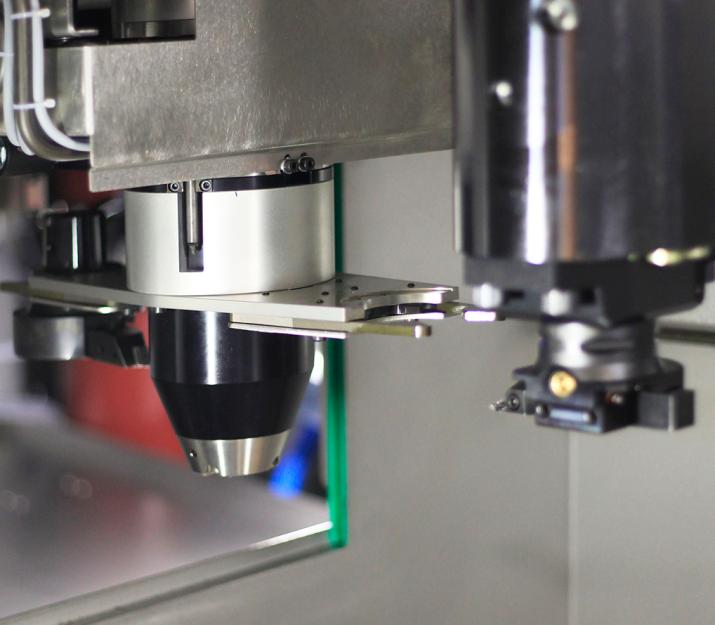

Granite base and main spindle housing

All components critical for precision are mounted on a natural granite base, which is inherently temperature stable and vibration-damping.

Plus vibration absorbing mounts isolate the granite base from the machine’s metal frame. Corrosion free and free of any stresses.

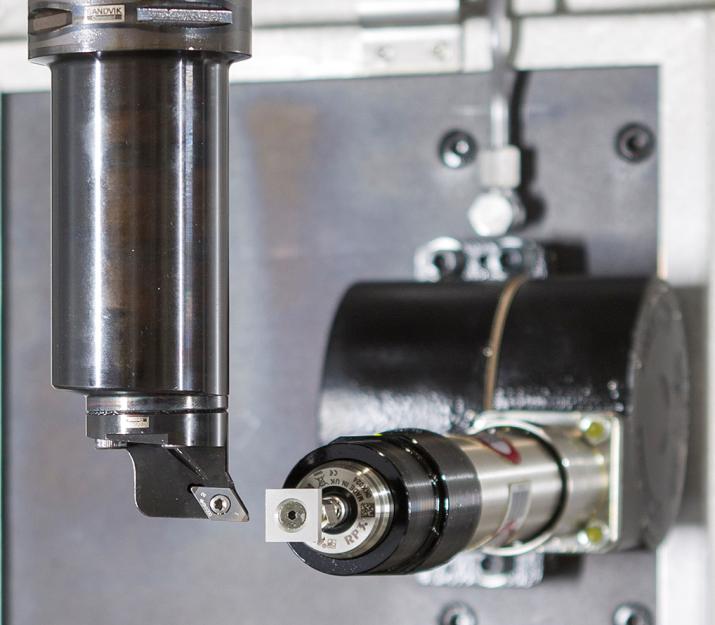

Wear-free hydrostatic guideways

High precision hydrostatic guideways with 0.00004” (1 µm) positioning and 0.000008” (0,2 µm) repeatability, controlled by linear guides.

Siemens or Fanuc control

Siemens Sinumerik One or Fanuc 321 CNC control, with 0.000,000,4” (0,01-micron) resolution.

Thermal stability

Heat sources and vibrating elements are placed outside the machining area, ensuring excellent thermal stability during series production.

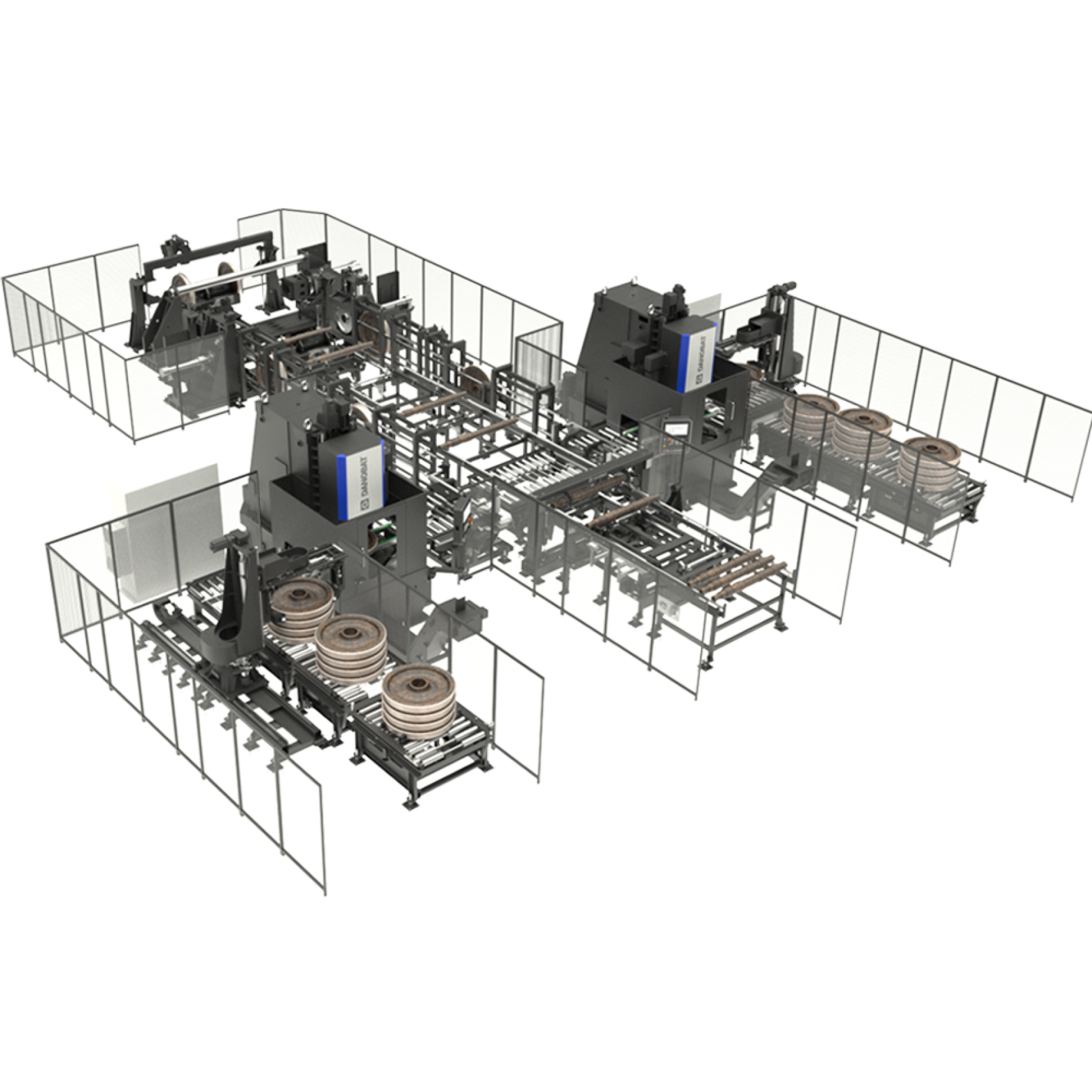

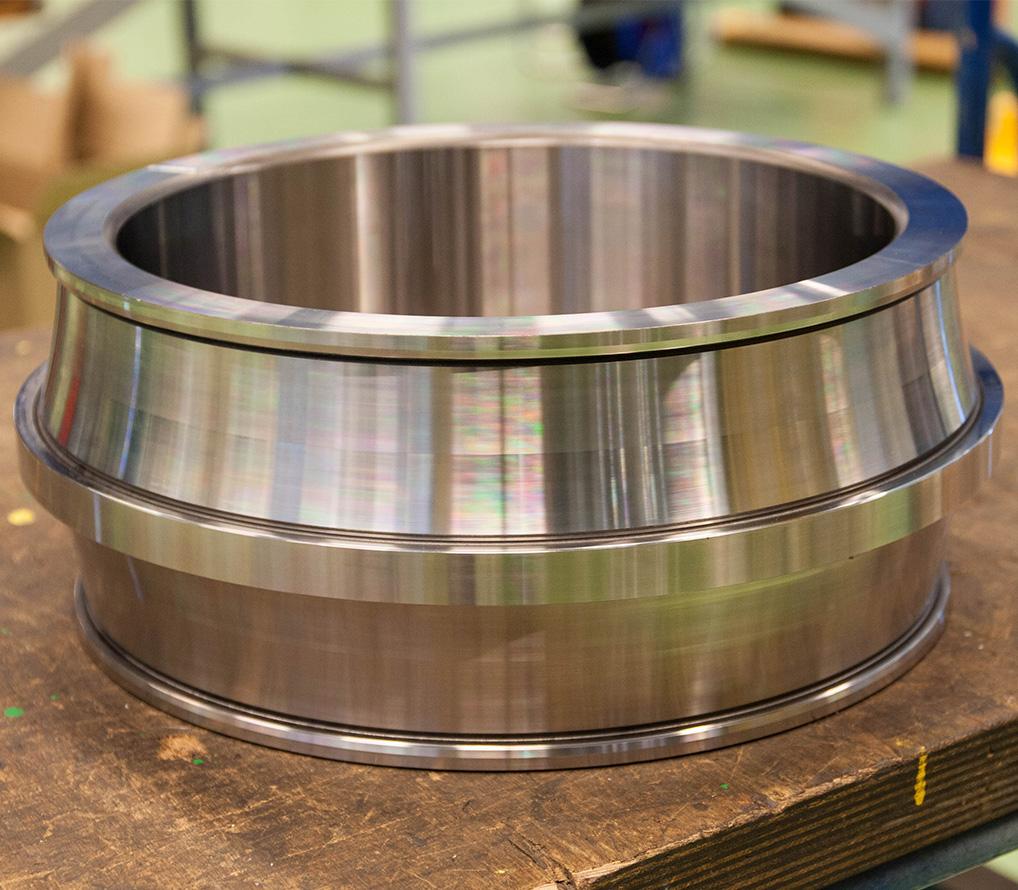

Inner & outer ring

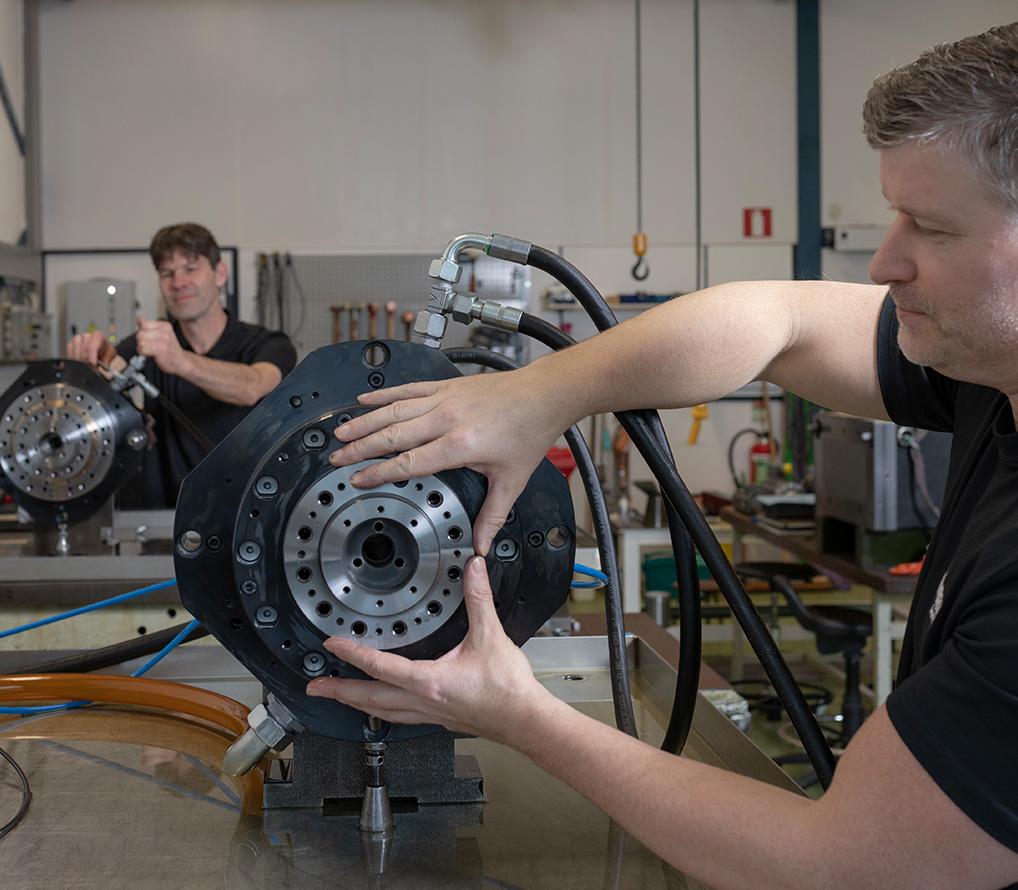

- Customized maintenance plans based on your production needs: ball bar test, verification of geometry and much more

- Retrofitting: We overhaul the complete machine or specific modules, such as the workhead and guiding systems

- Engineering and process development: Select the proper clamping and tooling solution for your new part