Email us

We automate

Reduce cost per part

Increase productivity

Adaptable to every floorspace

Reduce cycle times

Easy to use

Cover the sleepy shifts

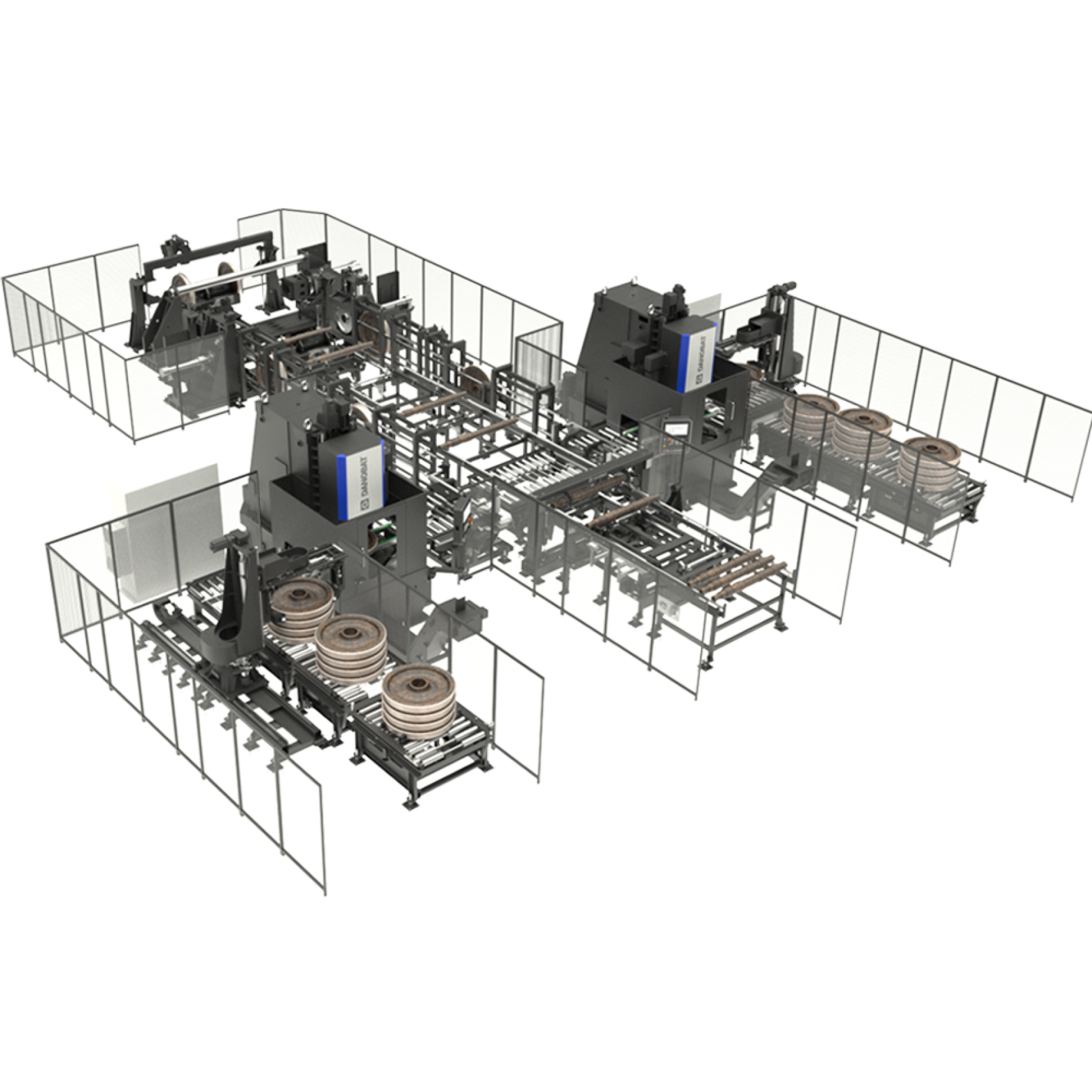

Defective parts are stored and can be retrieved by an operator.

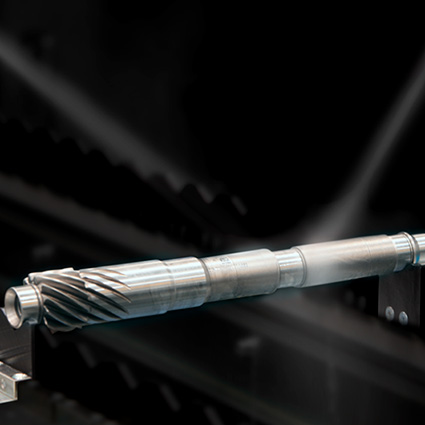

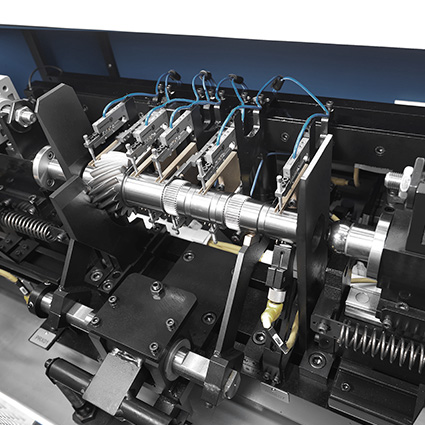

The part, once machined, enters a superfinishing operation using an abrasive belt or stone.

The machined parts are controlled, either randomly or after a certain number of machined parts.

The part is positioned for a correct subsequent machining operation.

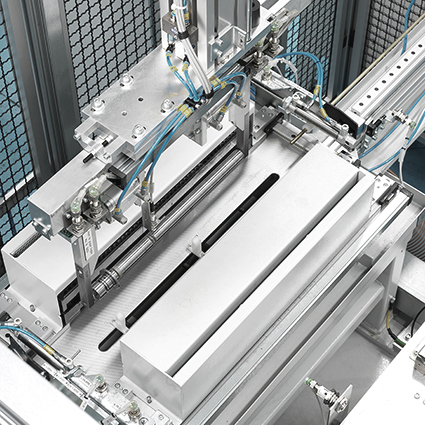

A protective layer is added to the already machined parts to prevent oxidation and improve their final aspect or image.

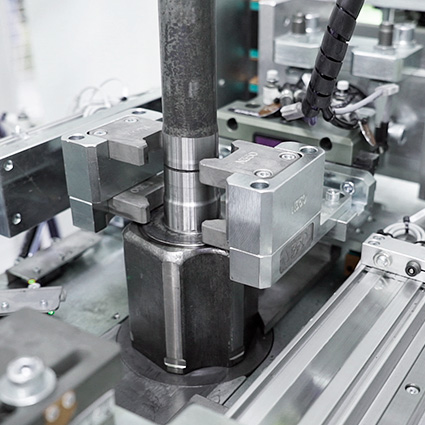

The part is measured before and/or after machining operations.

The part is dried and cleaned either by high pressure air, by centrifugal force or by an air suction system.

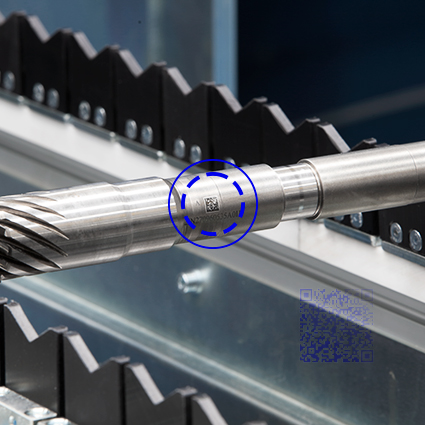

The part to be machined is identified, its reference code is verified or the part marked according to customer requirements (laser, micro-percussion, etc.).