Email us

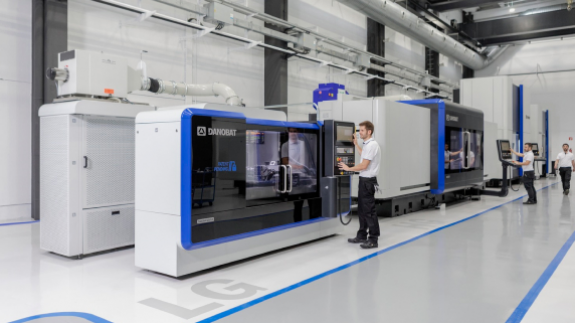

We automate

Reduce cost per part

Increase productivity

Adaptable to every floorspace

Reduce cycle times

Easy to use

Cover the sleepy shifts

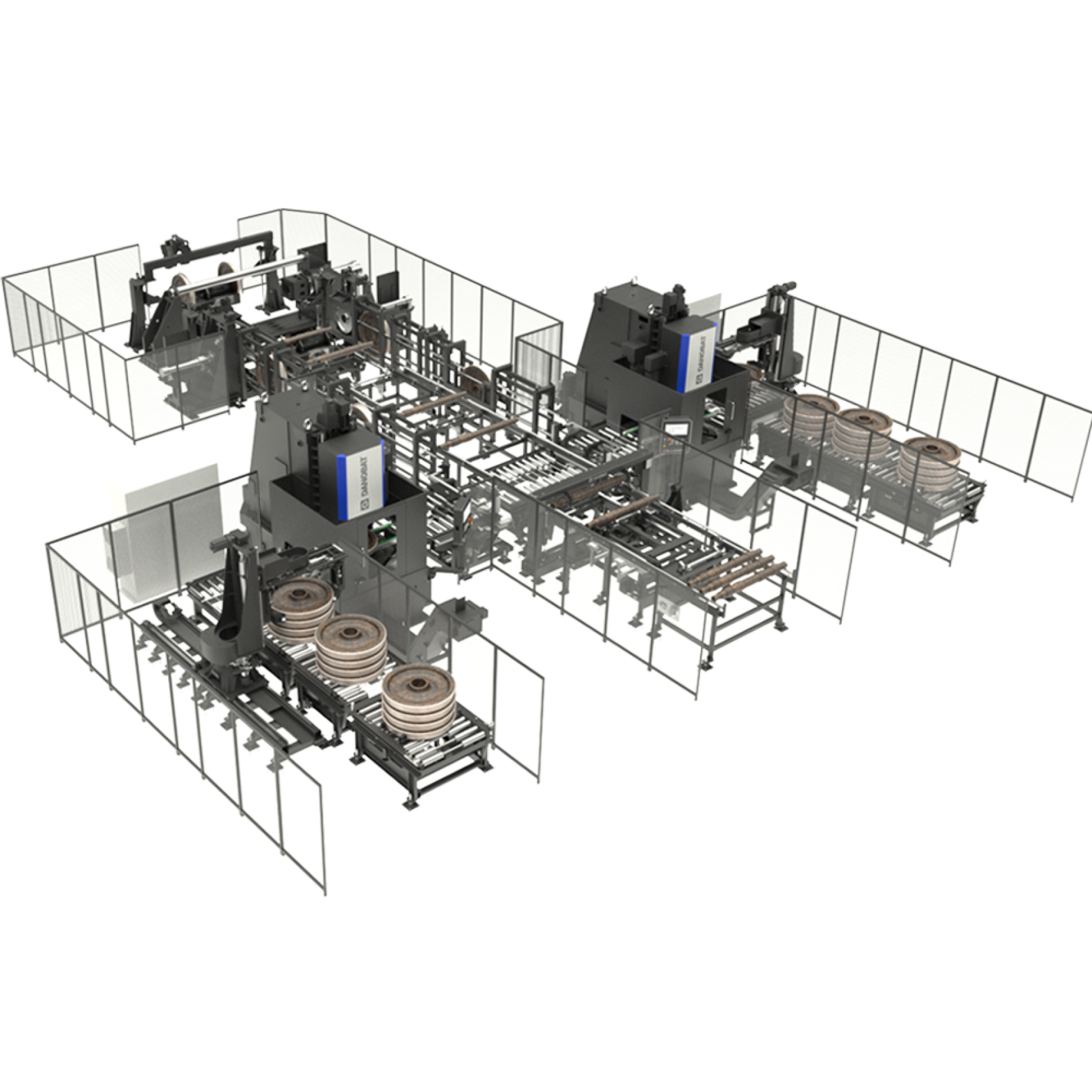

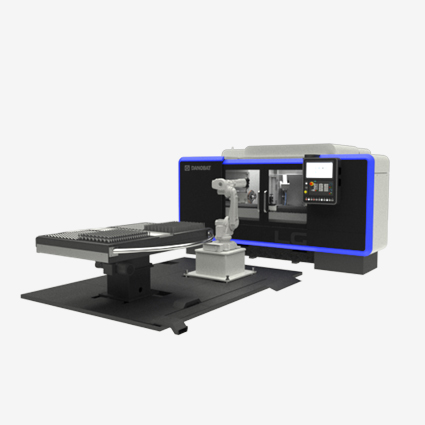

Robot

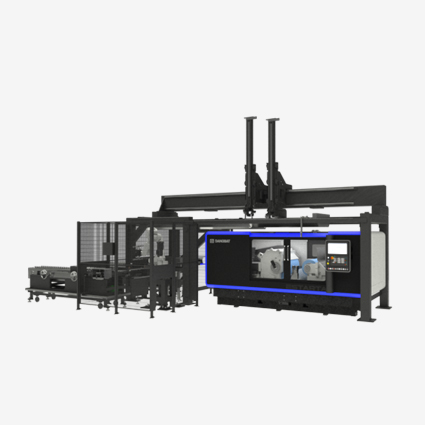

Gantry

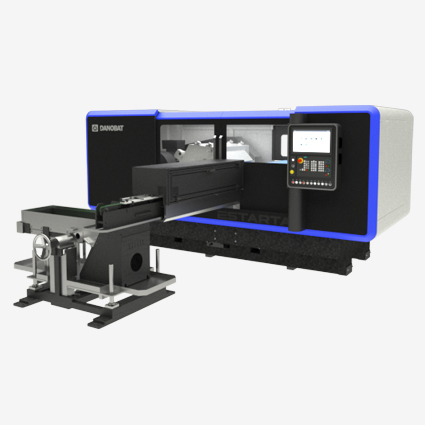

Hybrid

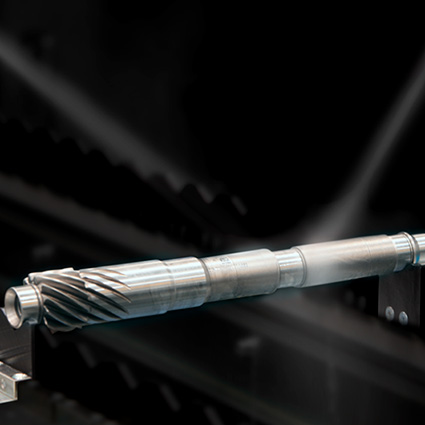

Centerless grinding — Throughfeed

- V supports step-by-step conveyor

- Chain conveyor

- Semiautomatic loader

- Step-by-step conveyor belt with spacers

- Friction conveyor flat belt

- Closed loop pallet conveyor

- Closed loop vertical rod conveyor

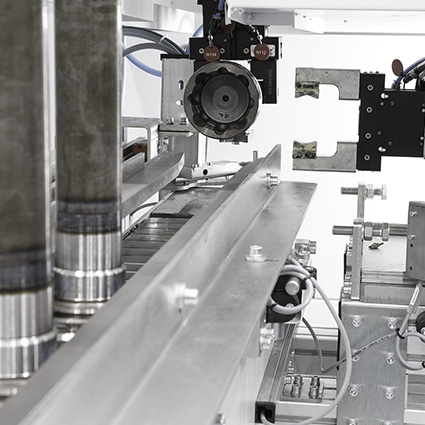

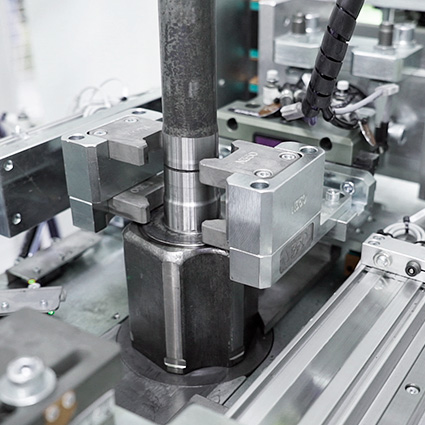

The part is positioned for a correct subsequent machining operation.

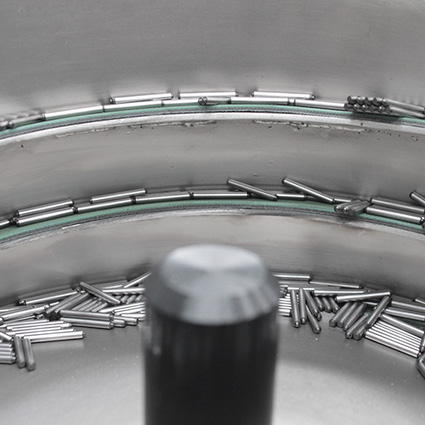

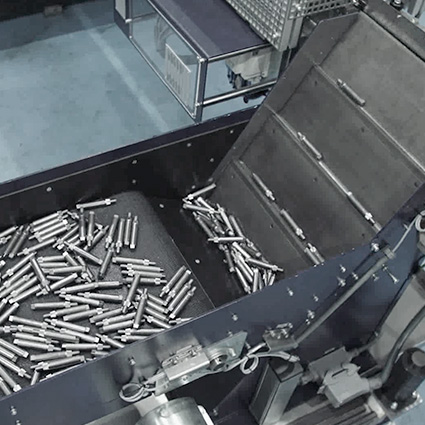

Vibration feeds a large number of parts that need to be loaded to the machine. This feeder is normally for small parts.

A protective layer is added to the already machined parts to prevent oxidation and improve their final aspect or image.

Pallet feeding system, with or without a trolley, loaded manually in the tower.

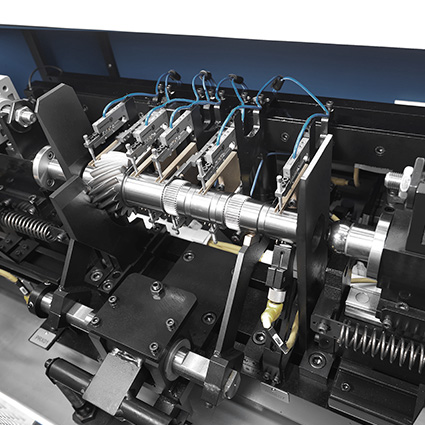

The part is measured before and/or after machining operations.

It feeds parts from the outside to the inside of the machine using a pipe and vacuum. It is designed for lightweight and small parts.

A robot with machine vision empties a container with randomly oriented parts. The robot can load and unload directly into the machine or feed another loader system.

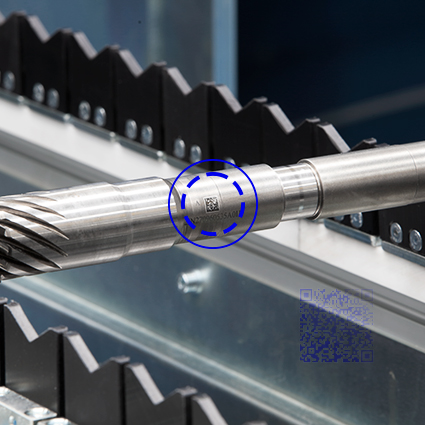

The part to be machined is identified, its reference code is verified or the part marked according to customer requirements (laser, micro-percussion, etc.).

The part is dried and cleaned either by high pressure air, by centrifugal force or by an air suction system.

Defective parts are stored and can be retrieved by an operator.

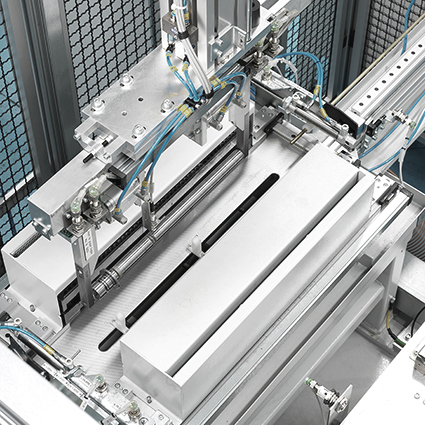

- Palletized double rotary table

- Low speed rotary or linear table

- Manual loading of pallets

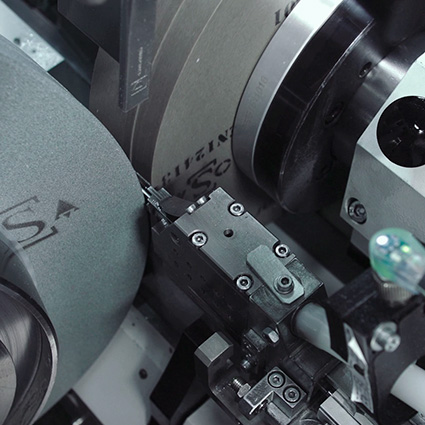

The part, once machined, enters a superfinishing operation using an abrasive belt or stone.

The operator feeds the initial drawer or basket with parts to be machined, and the hopper with elevator separates and accumulates them, usually on a feeding belt.

The machined parts are controlled, either randomly or after a certain number of machined parts.