Email us

- Home

- Automotive & e-mobility

Automotive & e-mobility

We offer grinding and hard turning solutions not only for machining ICE car components, but also for new parts that have appeared with the advent of electrics and e-mobility

In automotive & e-mobility industry, our machines are generally used for:

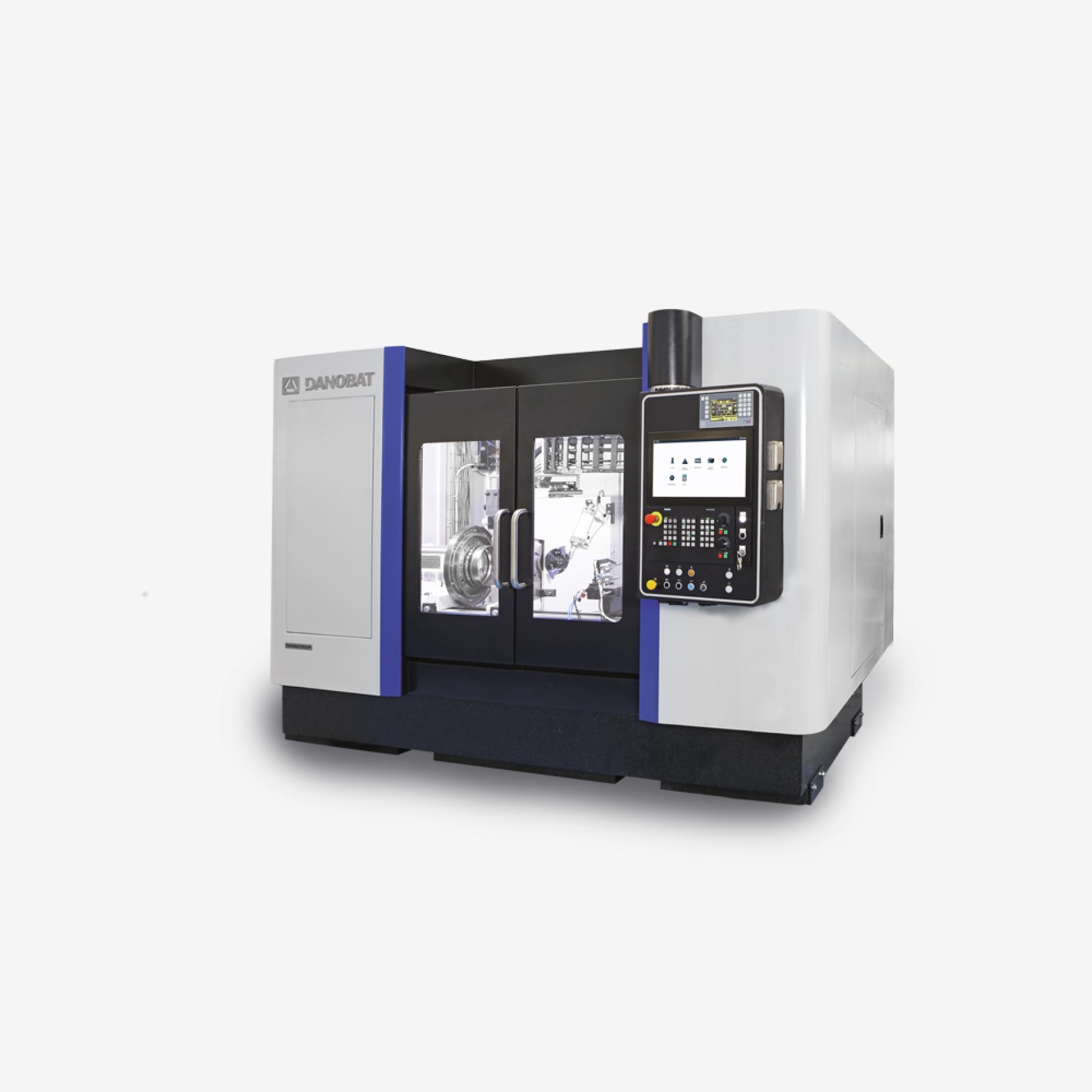

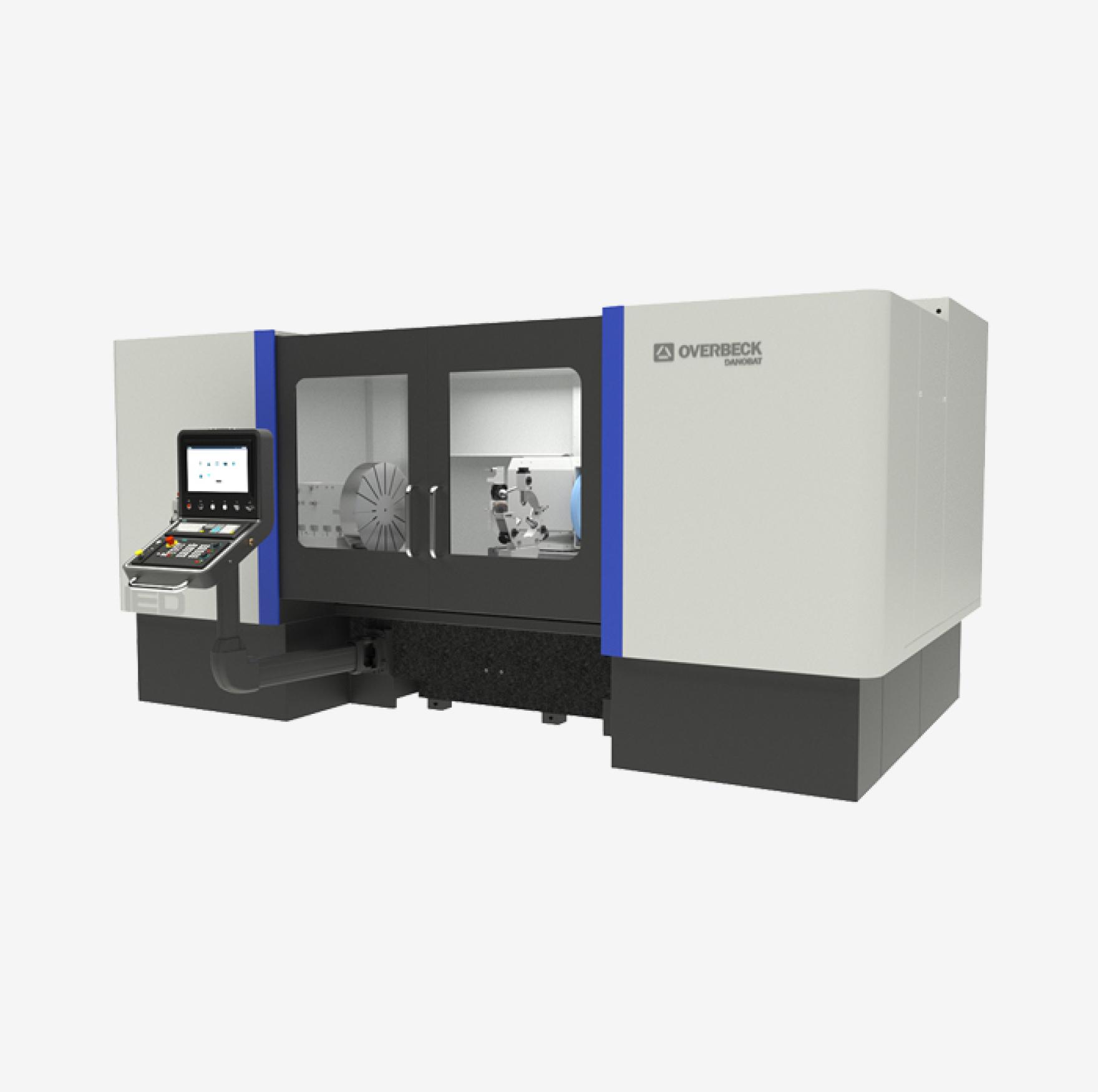

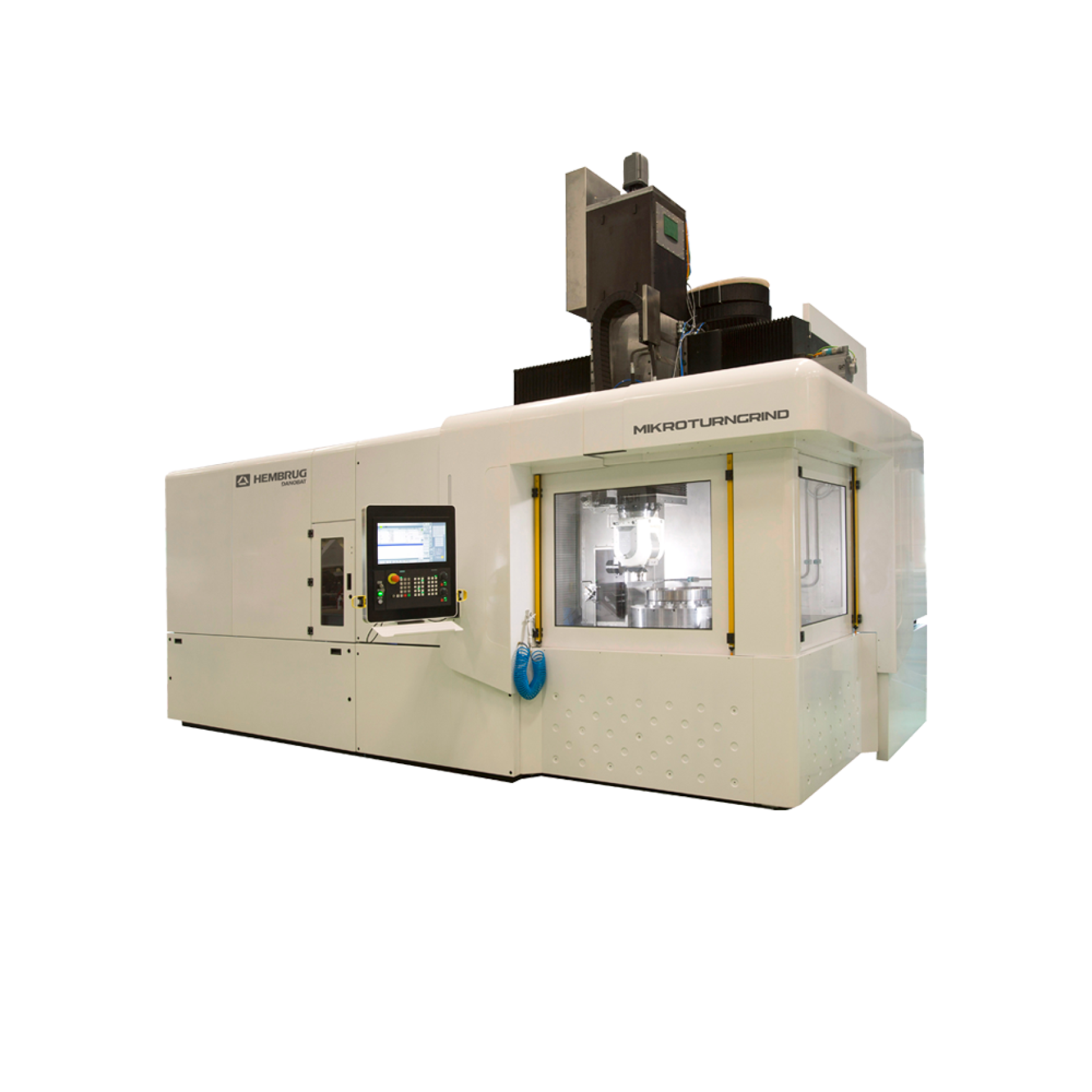

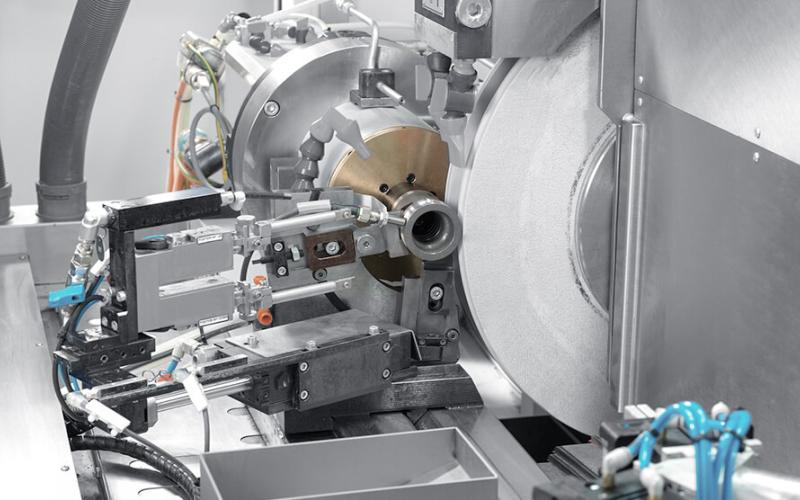

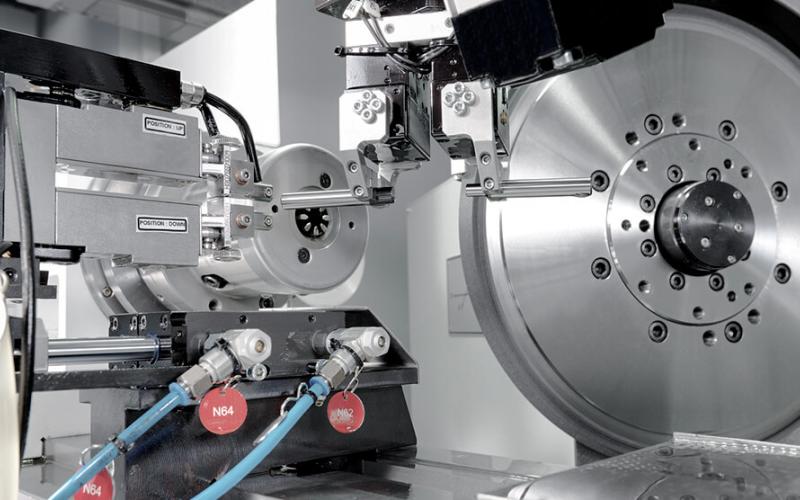

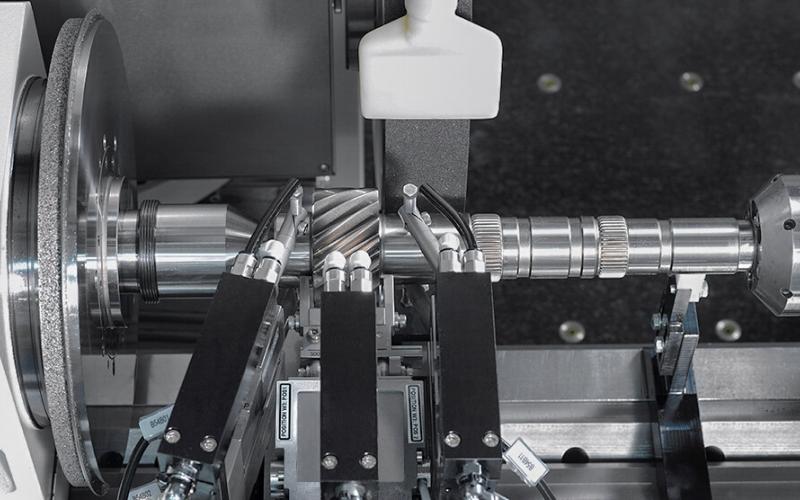

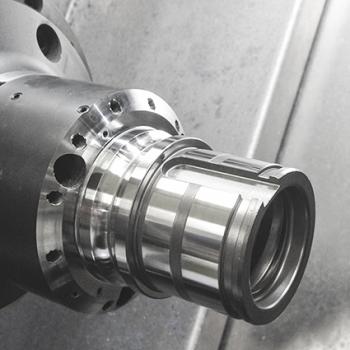

Complete grinding in a single set-up. We maintain very stable part geometry thanks to fast wheel profiling with a specialised internal dresser.

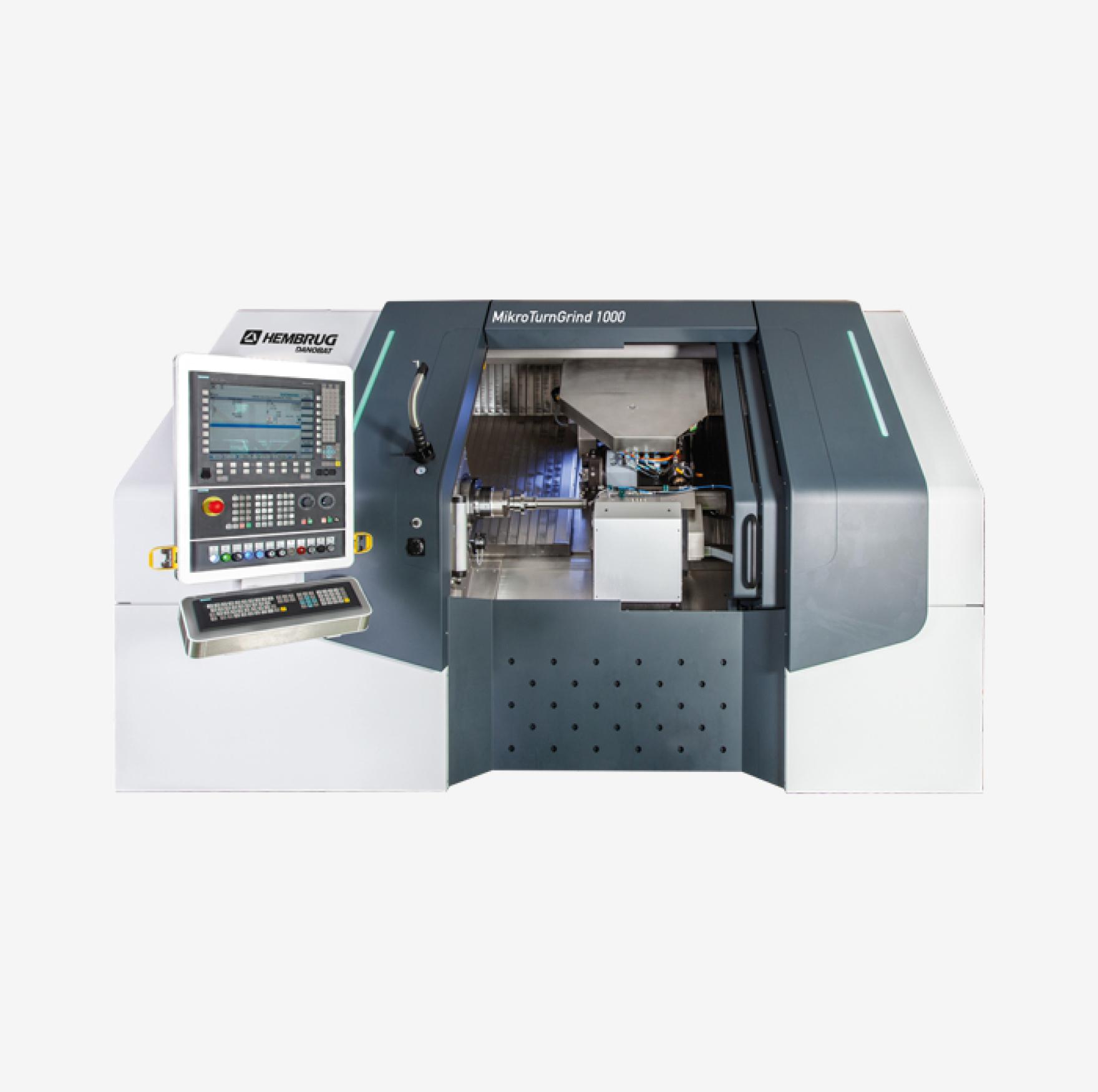

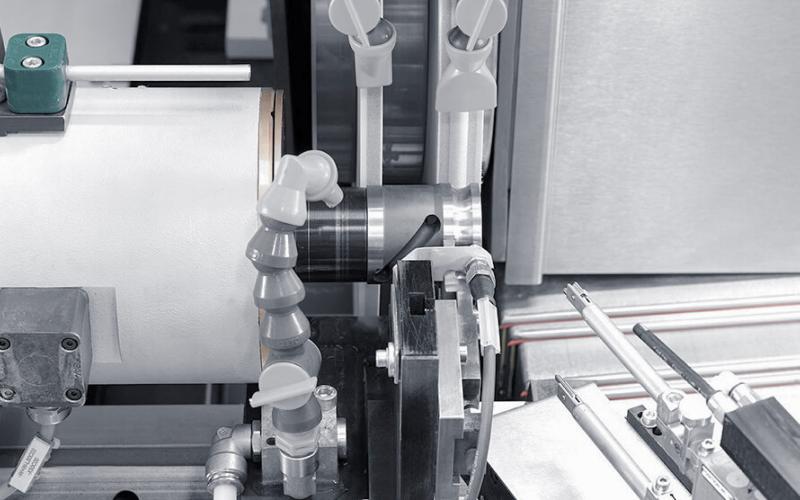

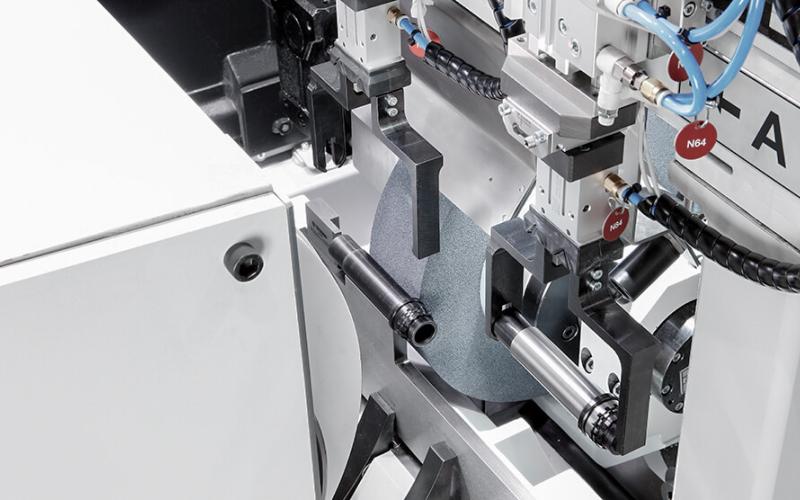

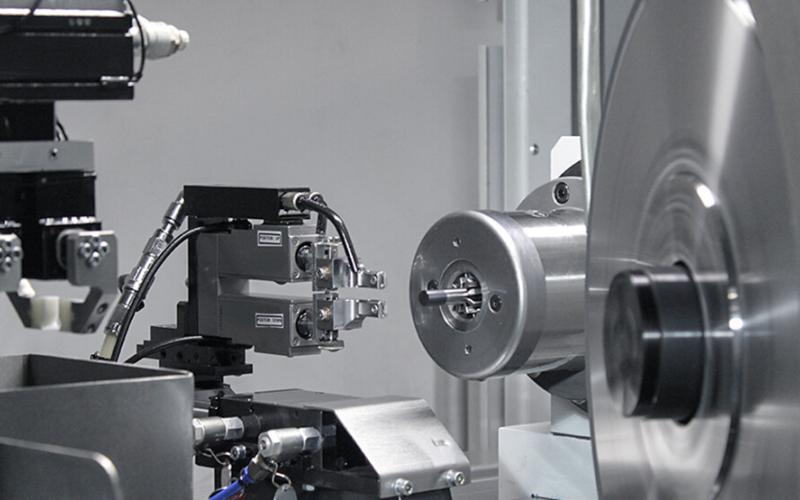

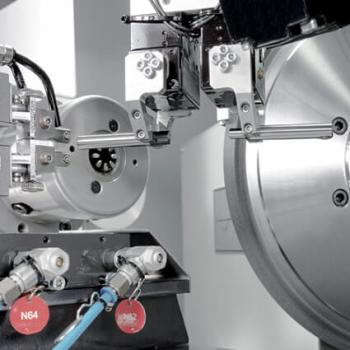

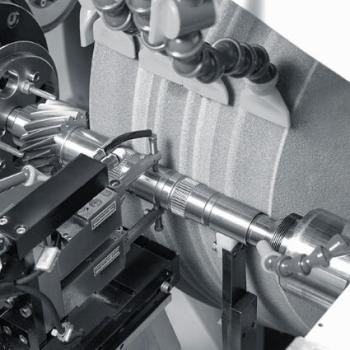

We master the machining process of ball screw nuts. Reduce process steps, decrease cycle time, and improve quality, at the same time.

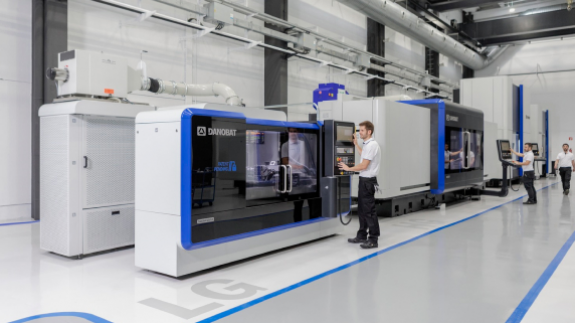

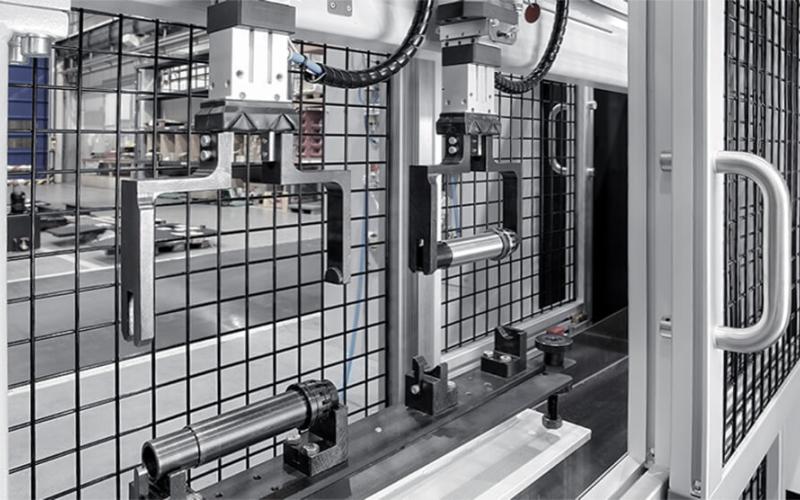

Depending on your manufacturing process, our centerless machines might be best. Or perhaps our cylindrical grinders? We will work in close collaboration with you to find the best solution.

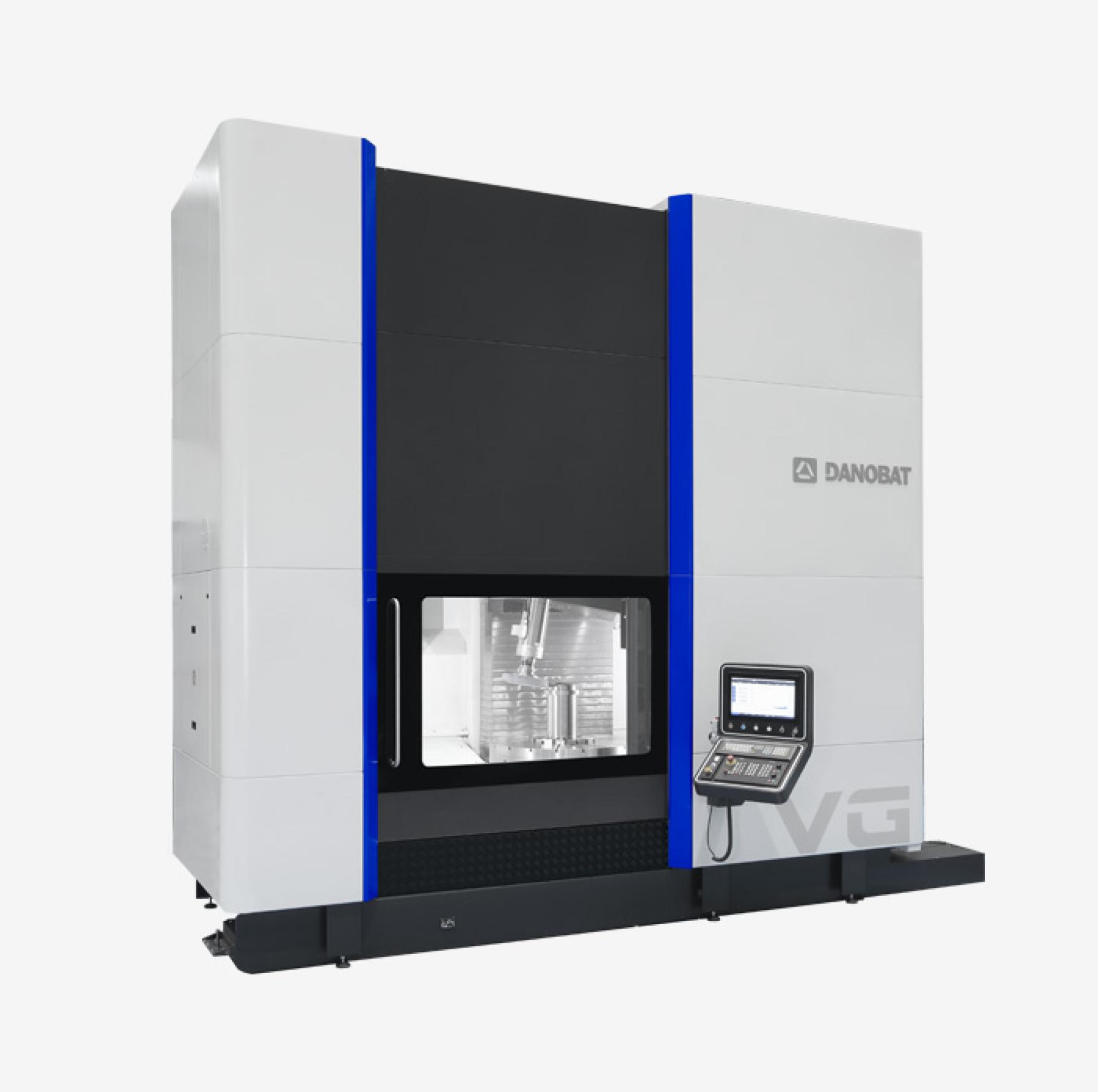

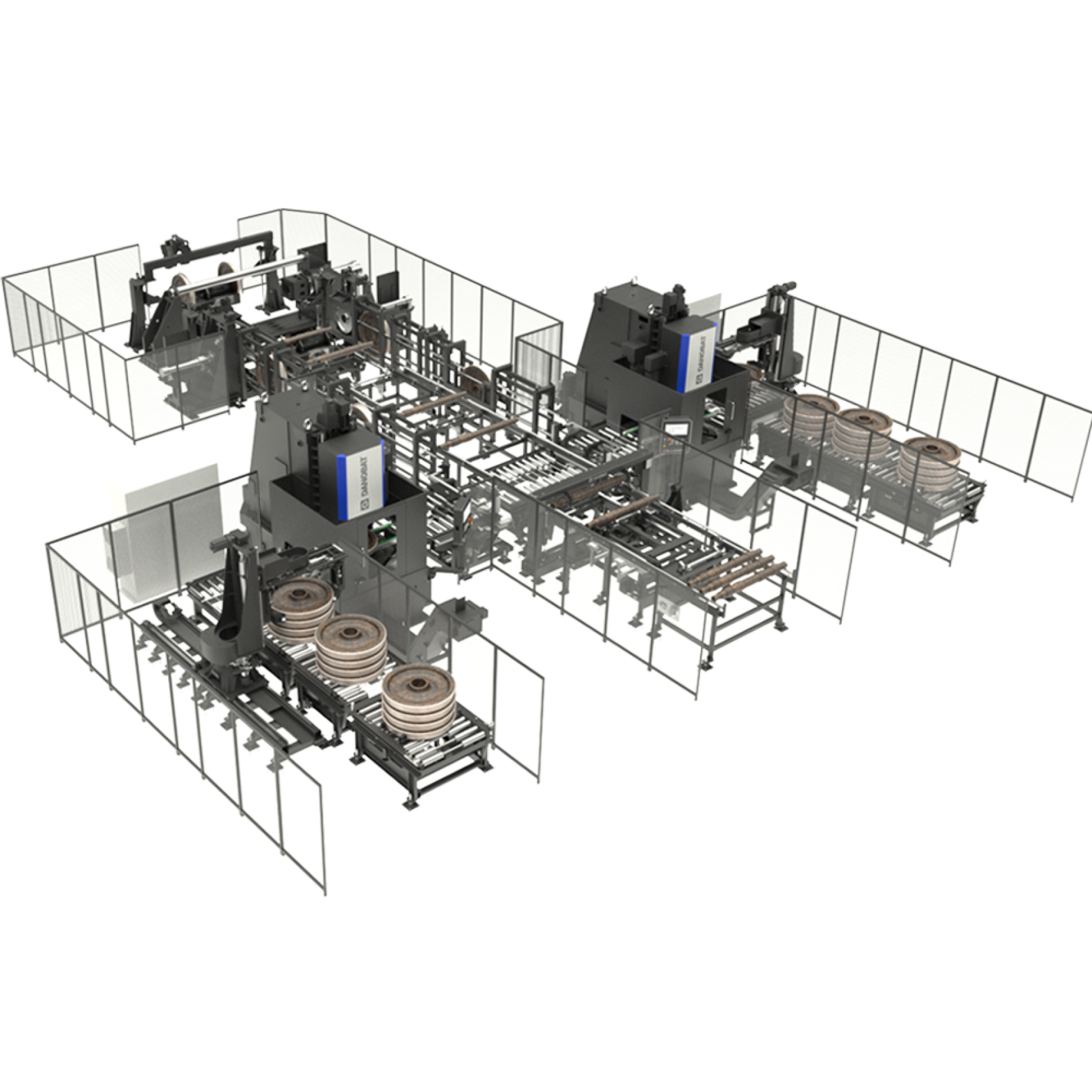

Over 30 years supplying vertical lathes and turnkey production lines to key players in this niche.

We master the machining process of ball screw nuts. Reduce process steps, decrease cycle time, and improve quality, at the same time.

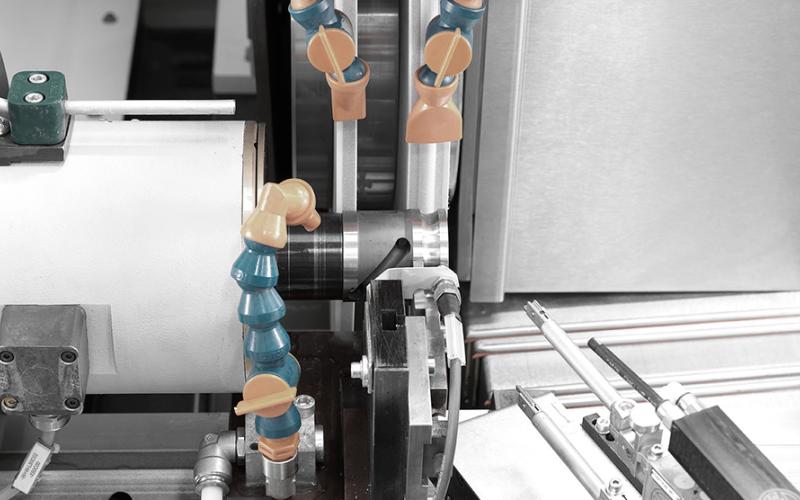

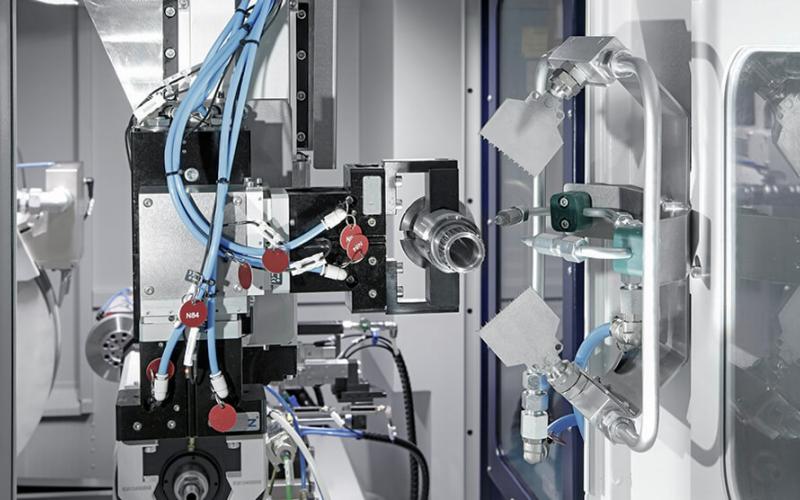

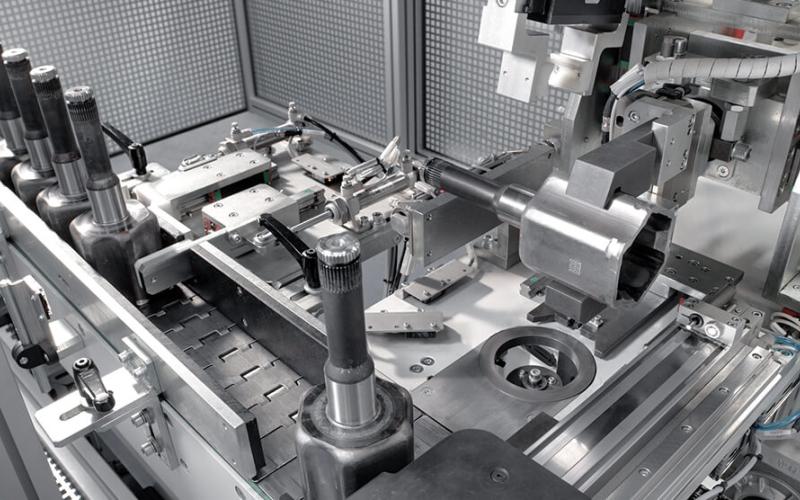

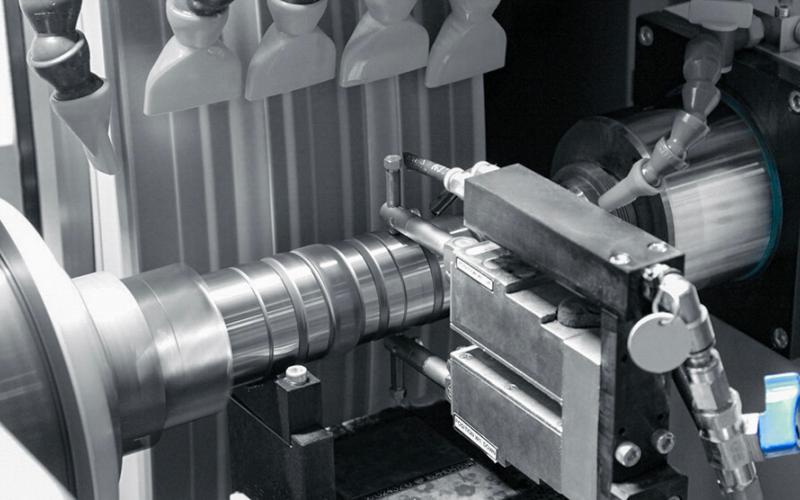

User friendly software, together with our unique OptiDress, combined with our quick changeover loading system, will allow you to change references in the blink of an eye.

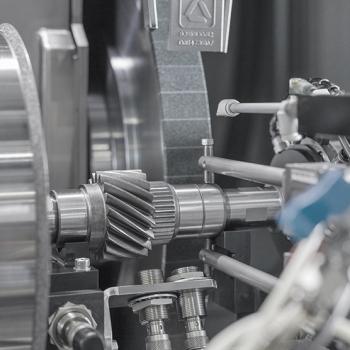

Guaranteed precision is the key factor in this case. You will get the best results with a combination of process stability and maximum availability.

In collaboration with key players in this niche, we have developed the most productive solution in the market.

The best solution? There is never just one "best solution." It really all depends on the part size, the lot size, the production capabilities of your equipment, and several other factors.

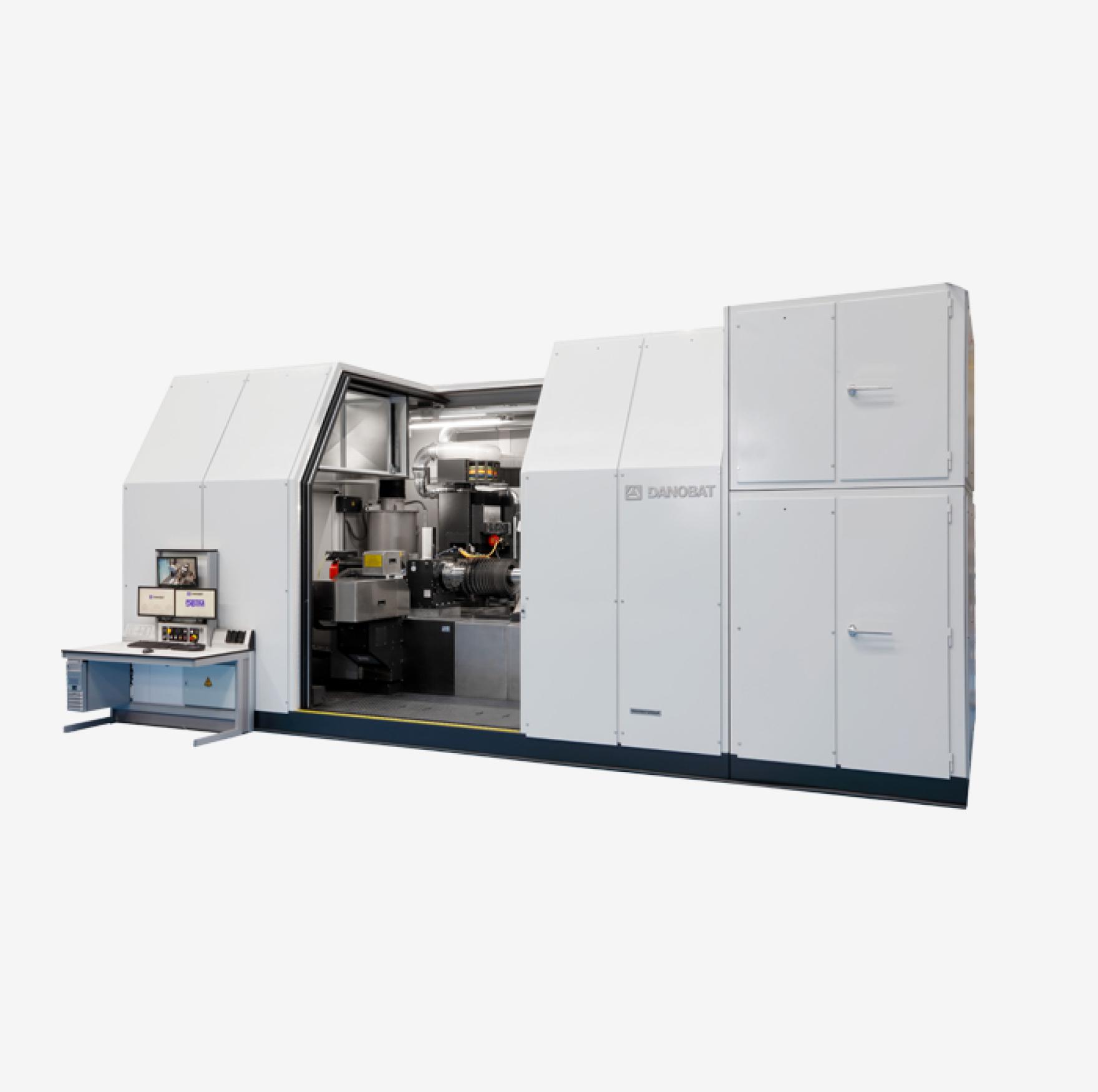

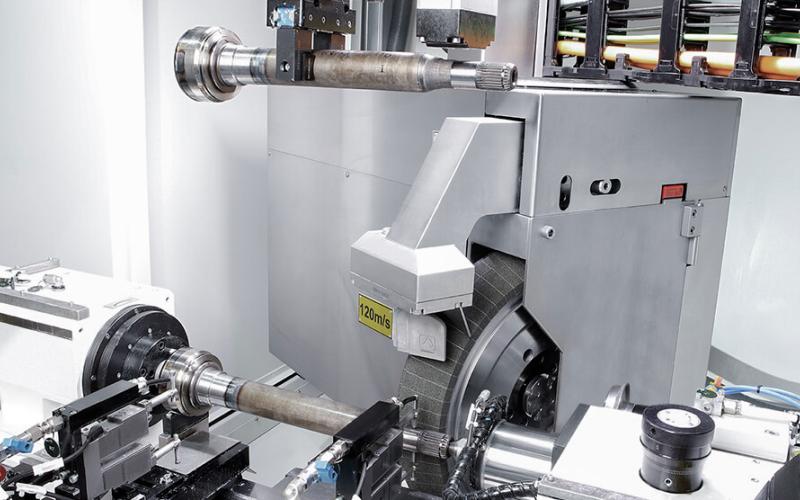

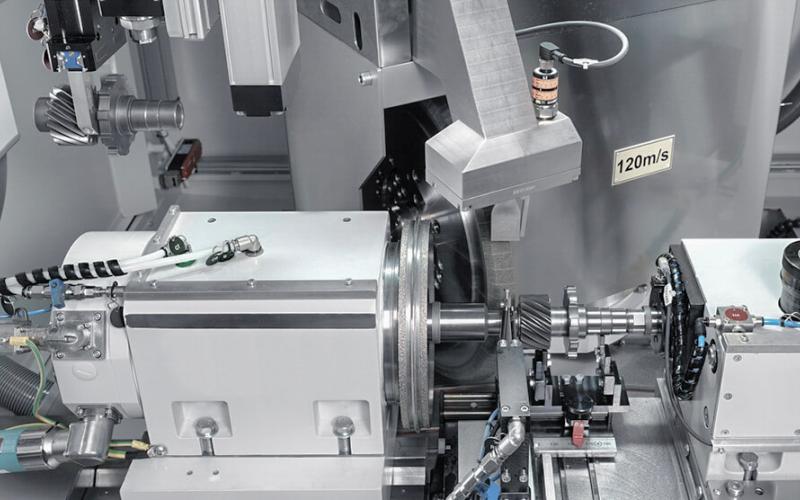

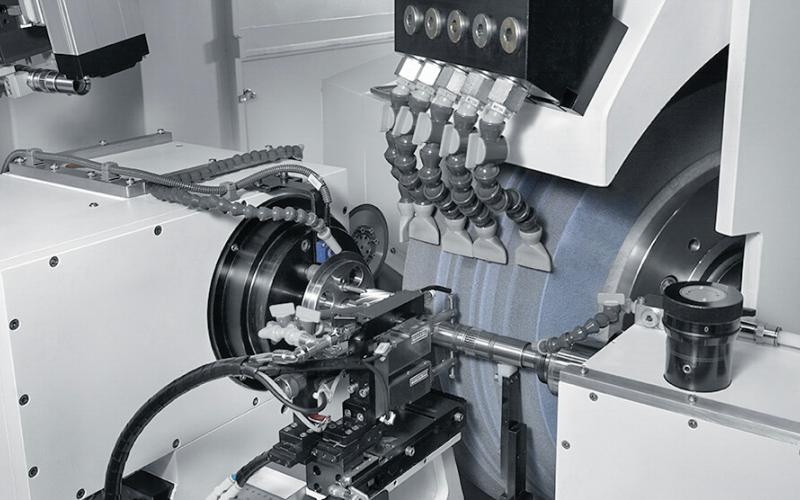

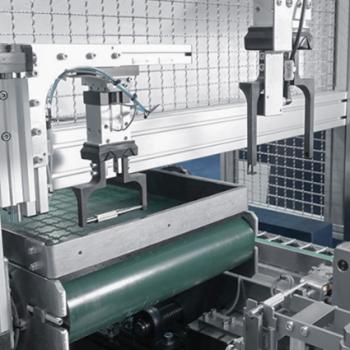

Very short cycle time thanks to high-speed CBN grinding with high stock removal, and the integration of a conveyor with a gantry system. More than 1.000.000 components per machine/year.

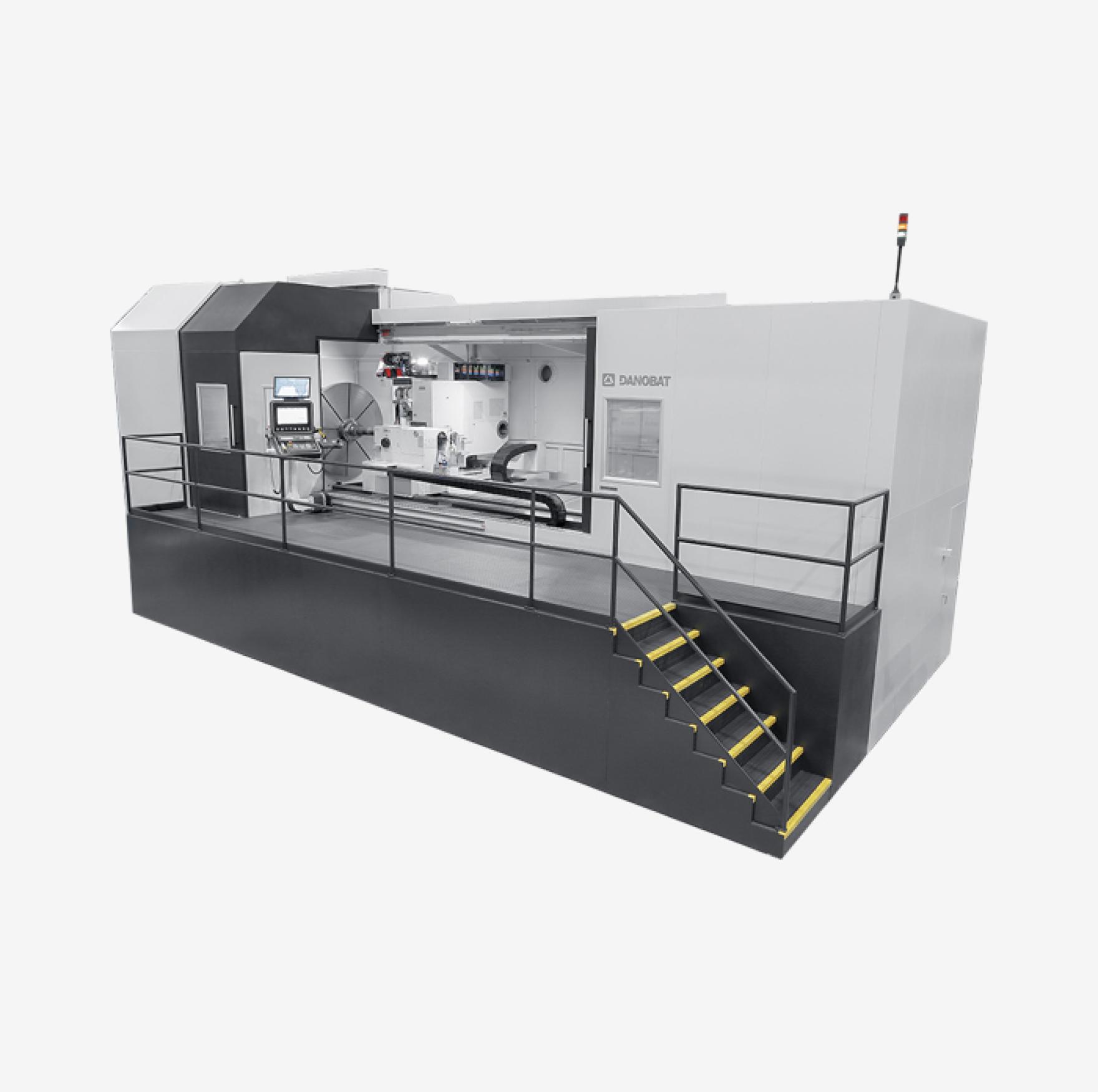

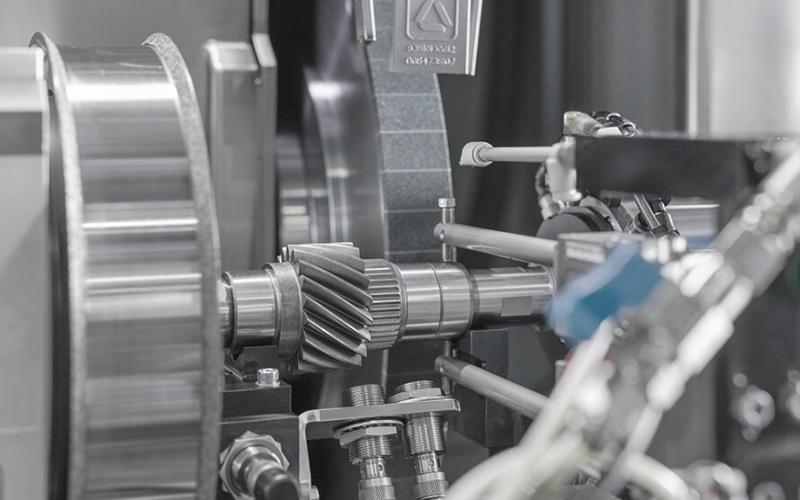

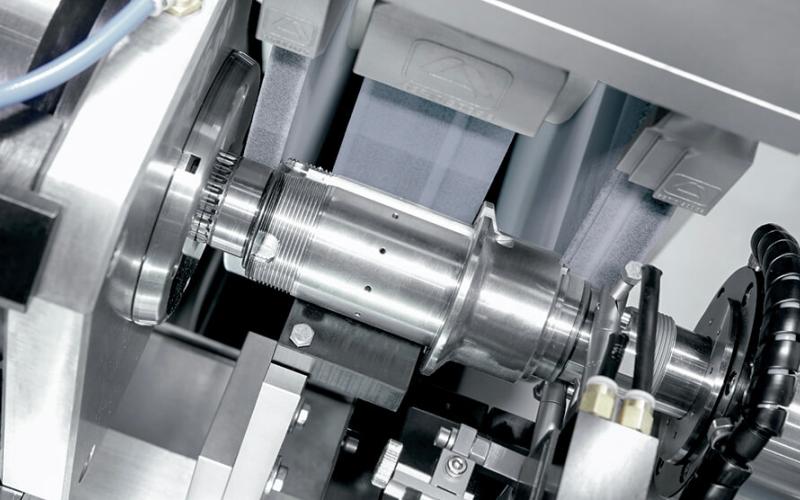

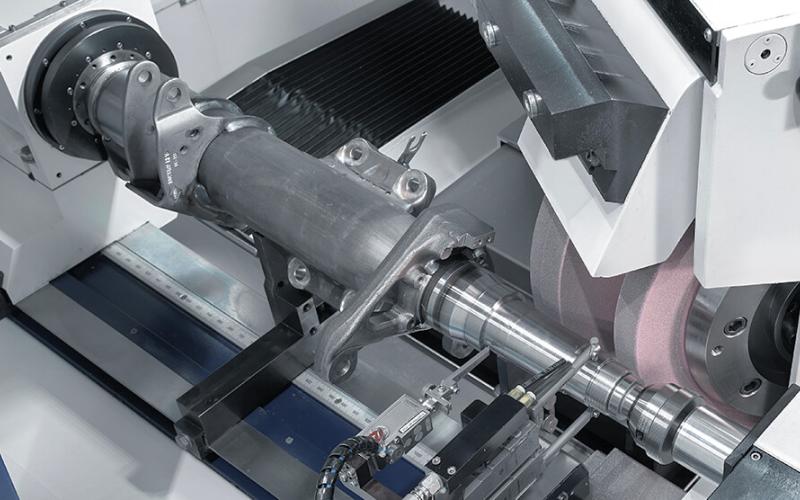

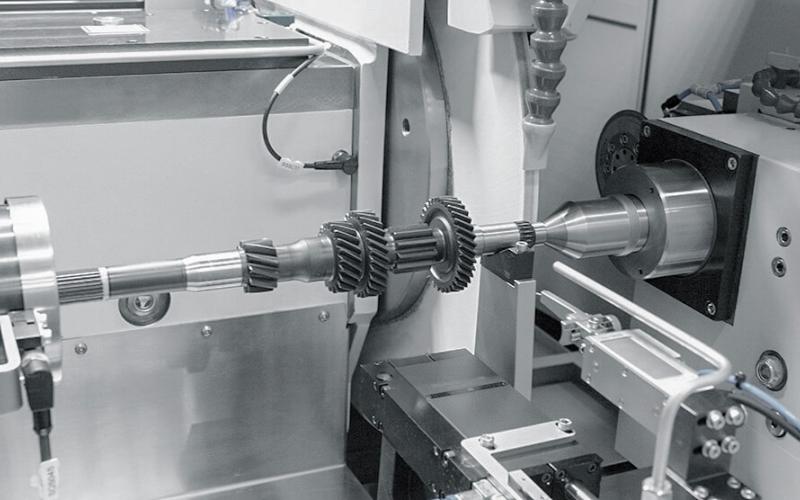

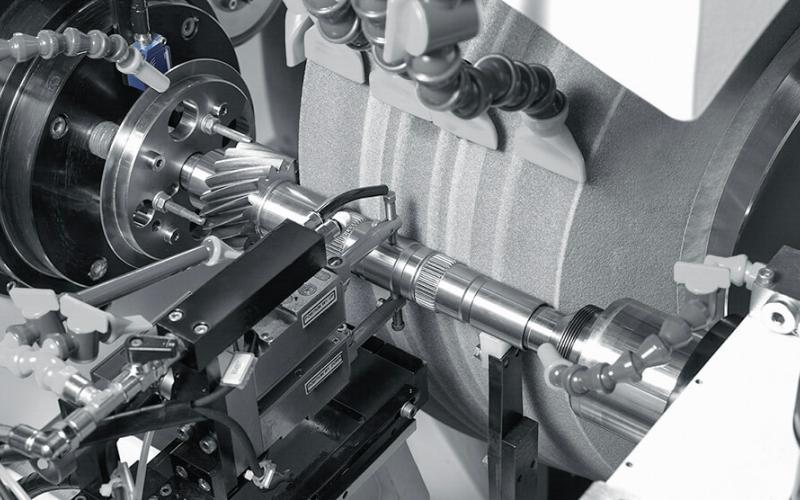

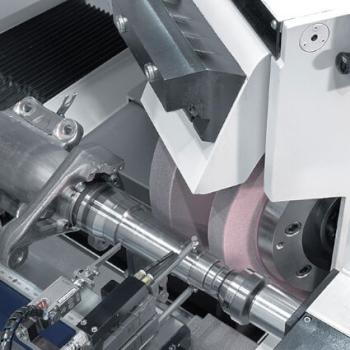

We know the importance of flexibility when machining these types of parts. The machine's mobile tailstock will give you what you are looking for: quick reference changeover.

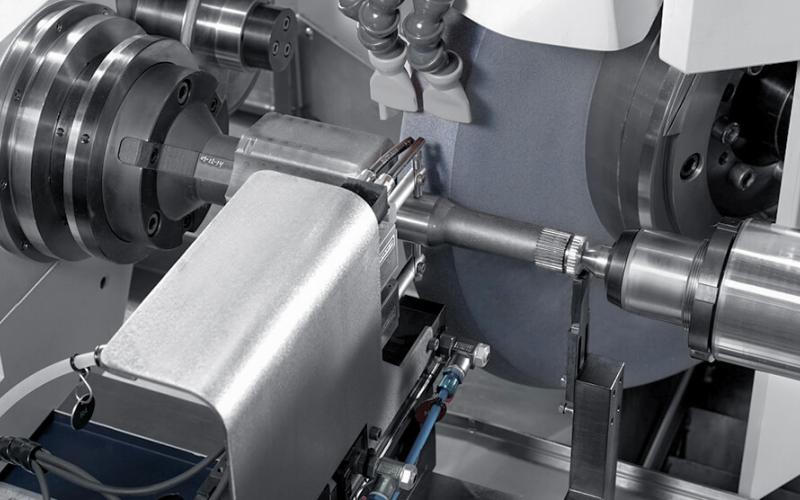

Best solution for long and short driveshafts, delivering the highest output with just one machine. BL1 configuration for long driveshafts.

We guarantee meeting the tight tolerances these manufacturers require, with the maximum productivity. Customised loading systems for really small parts.

Our superb centerless machine allows you to grind multiple parts per cycle, under the most stable conditions, and with a very competitive cycle time.

Complete grinding in a single set-up. We maintain very stable part geometry thanks to fast wheel profiling with a specialised internal dresser.

Challenge: Guaranteeing maximum output. Solution: Grinding the part's different materials with a tandem wheel, plus automated (un)loading.

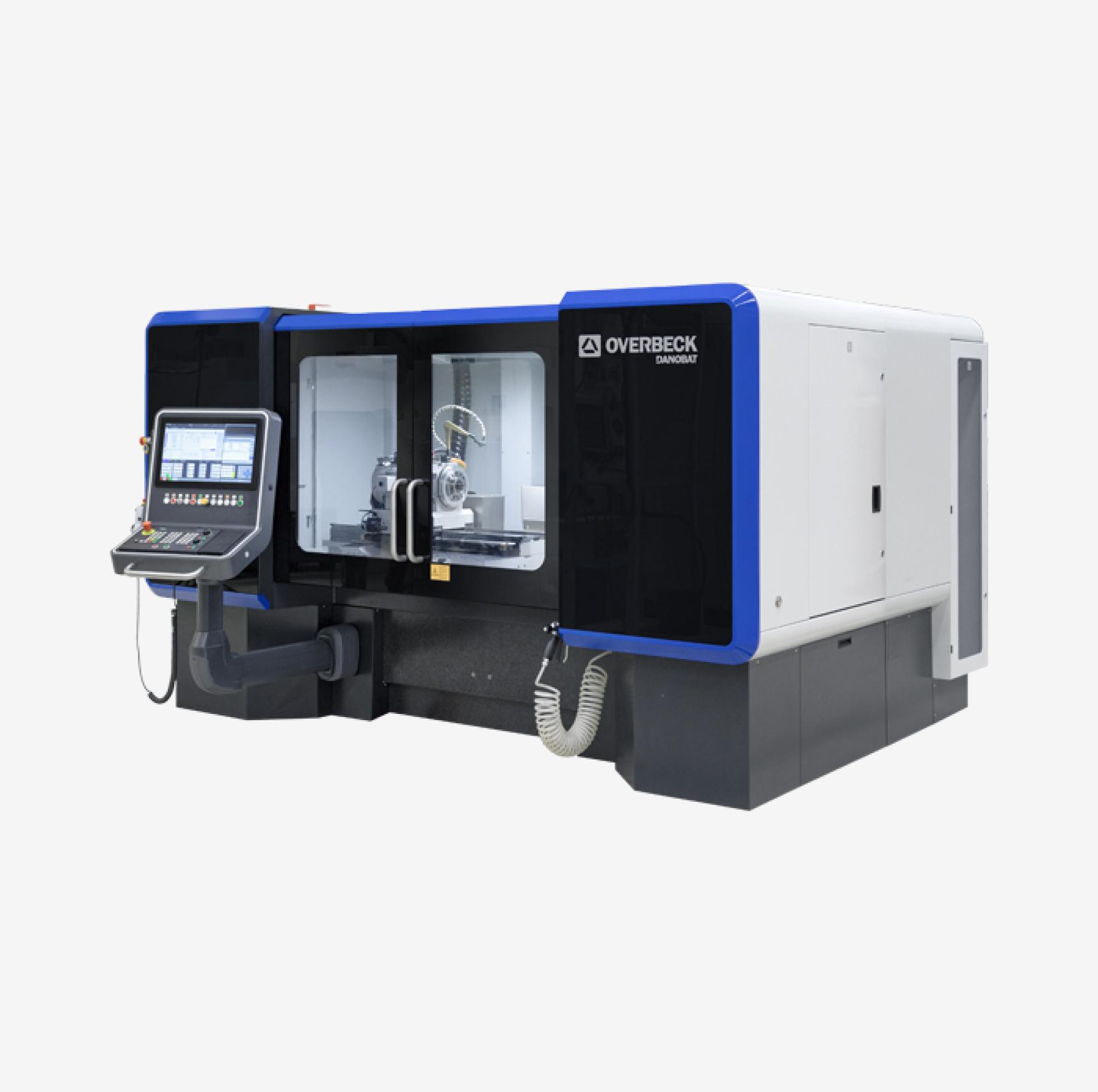

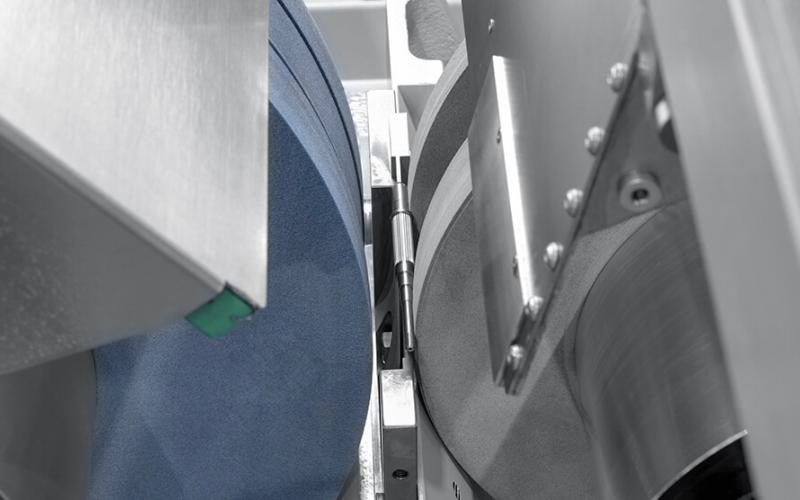

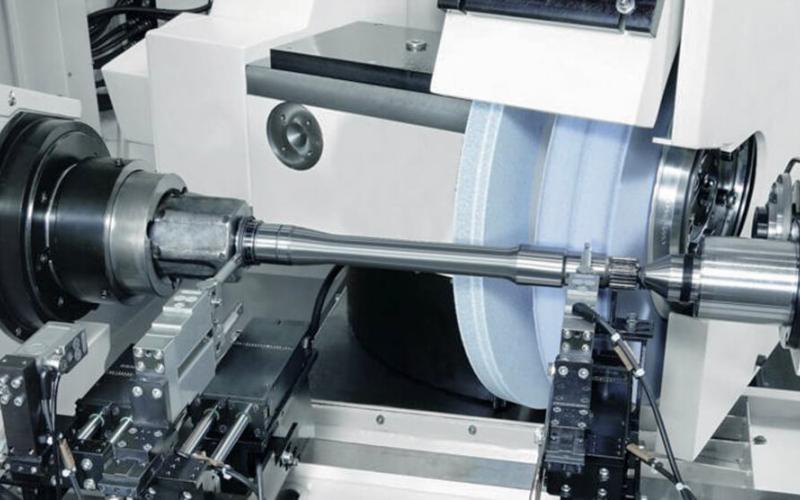

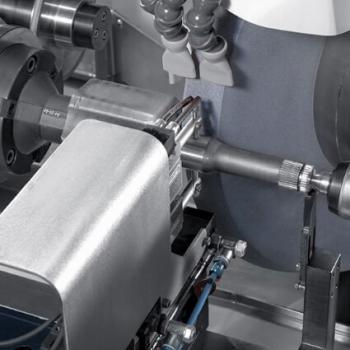

We offer you the right solution for steering rack grinding. Our Estarta machines include grinding wheels of up to 650 mm in width. Not wide enough? Contact us.

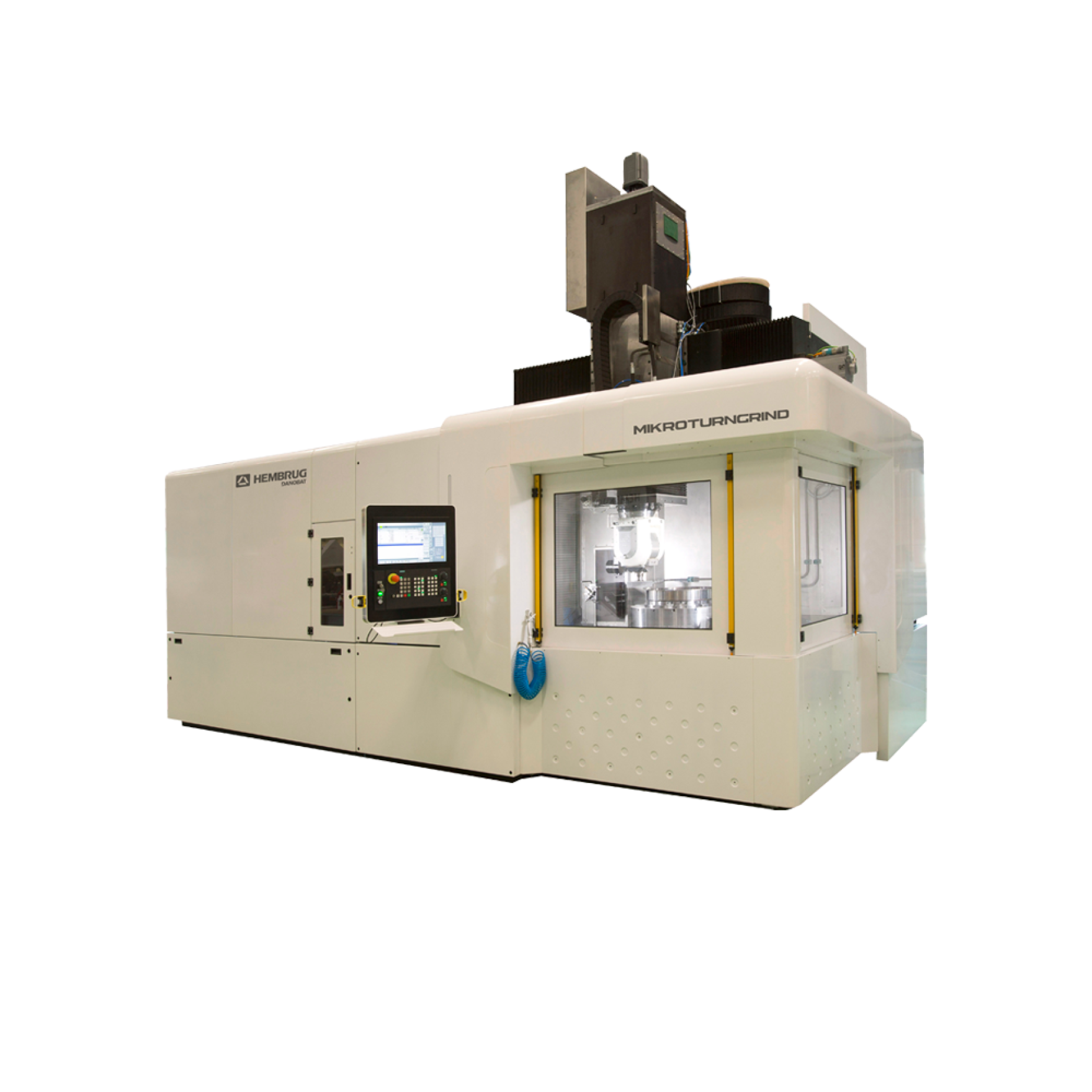

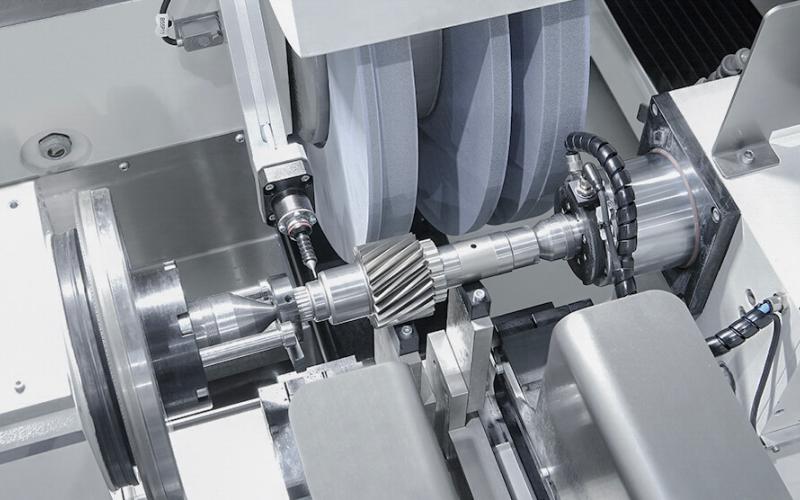

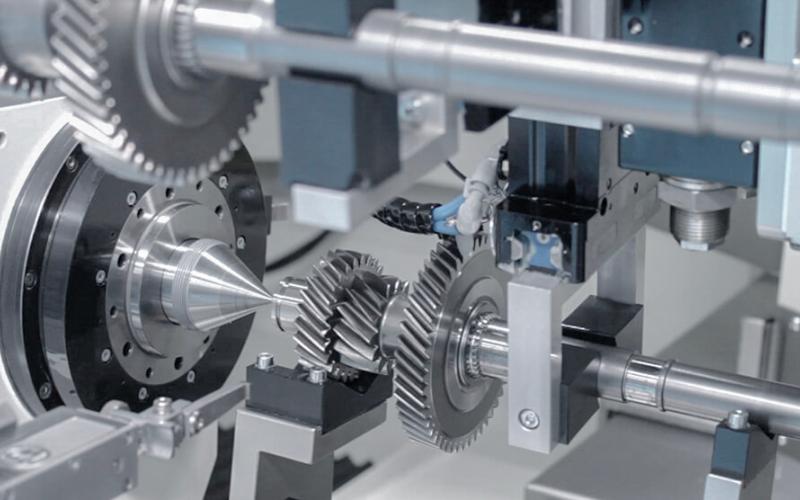

Our solutions have been conceived to perform all needed machining operations, including face grinding, in one clamping. Dimensional, roughness and geometrical tolerances are guaranteed.