Email us

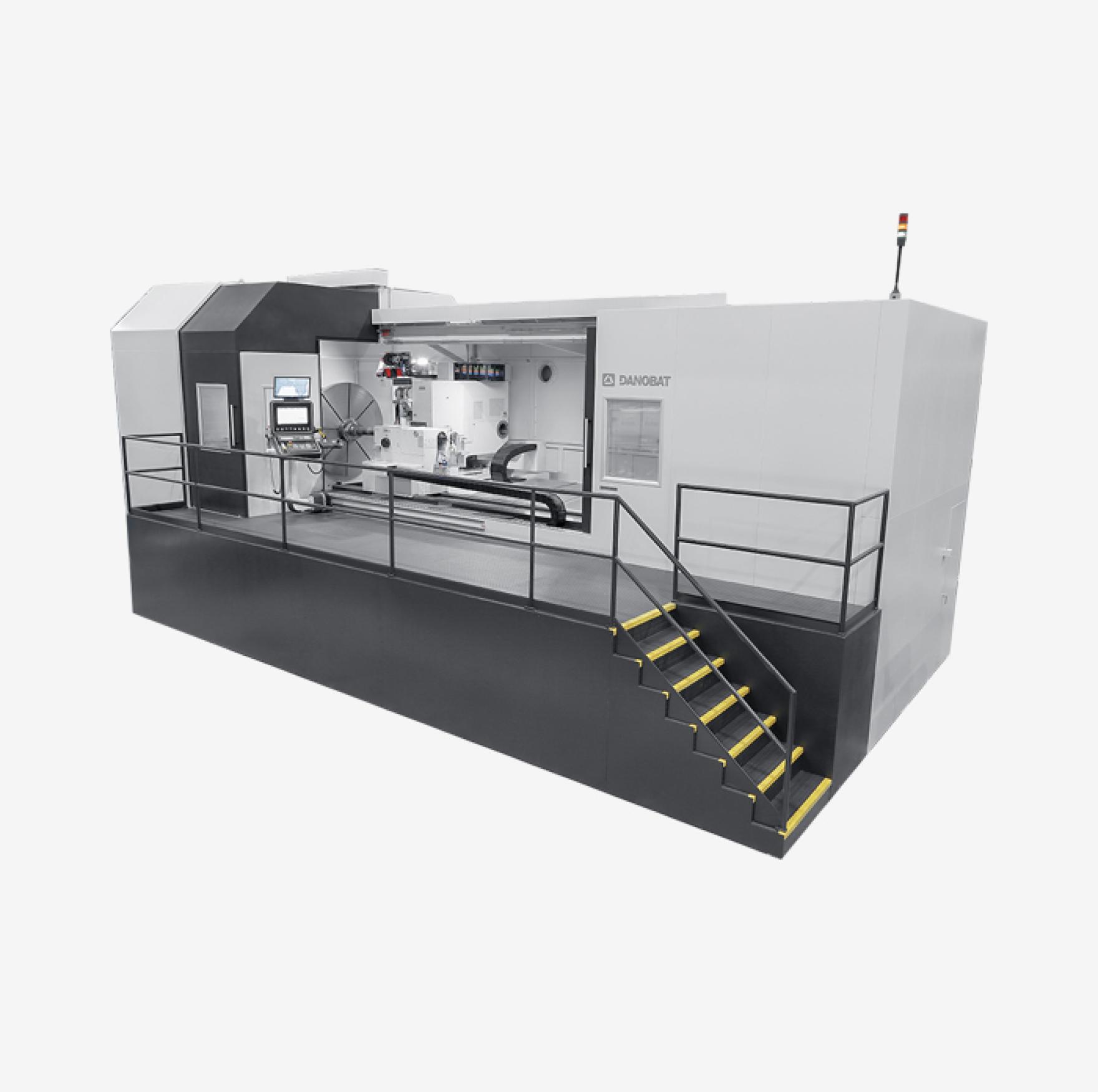

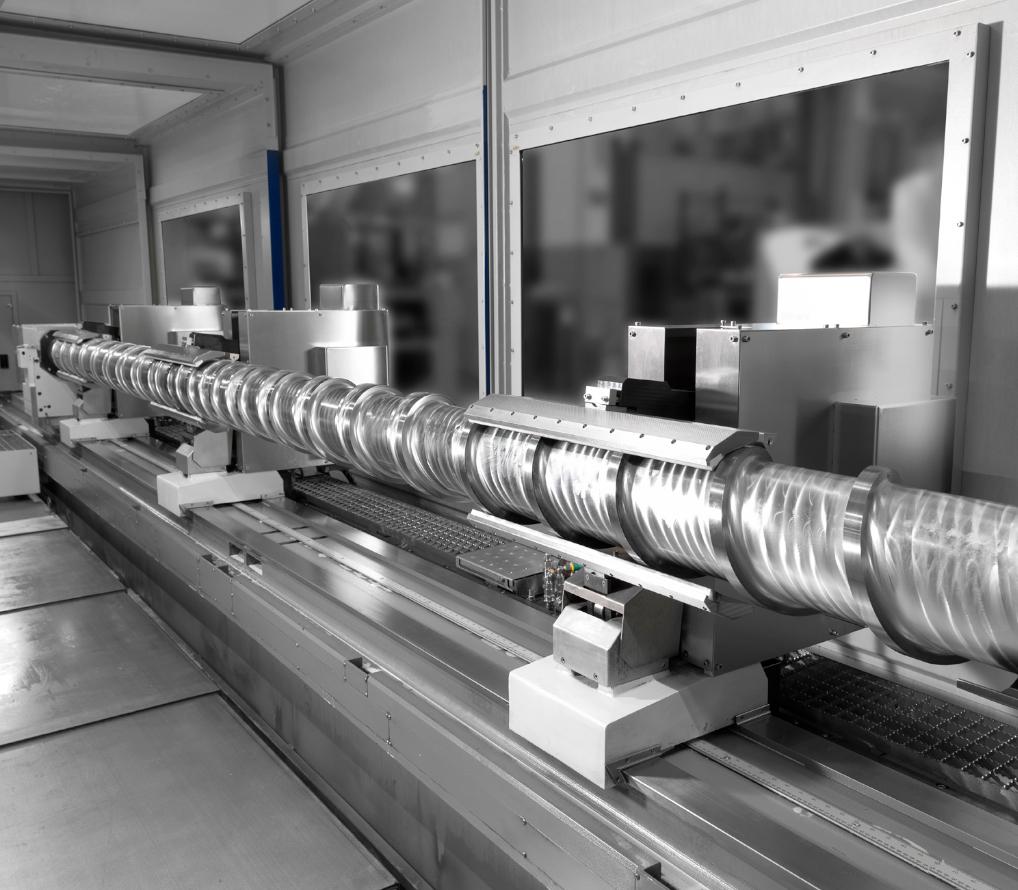

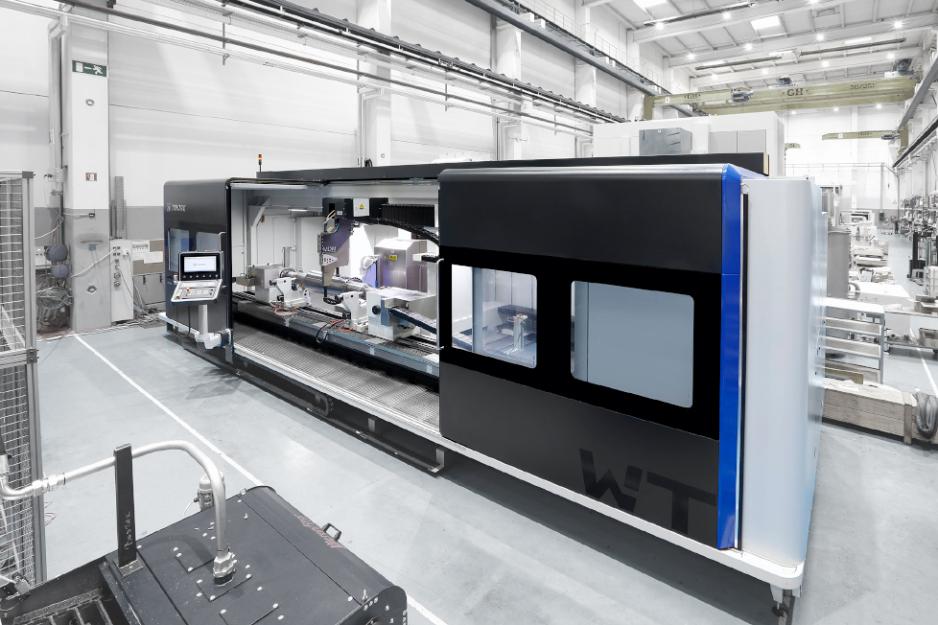

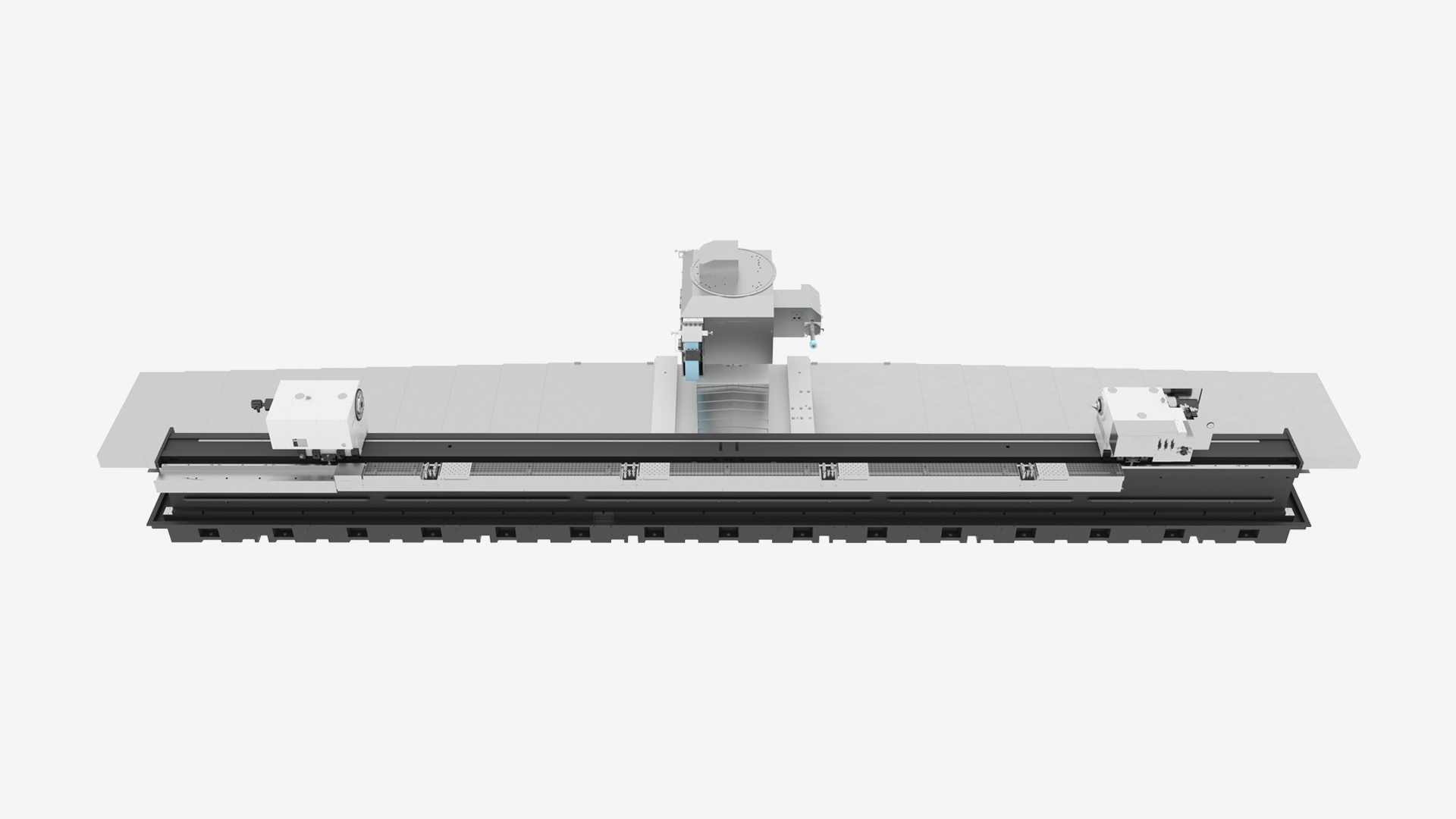

XXL HEAVY DUTY GRINDING MACHINE

WT takes care of every detail in order to machine XXL workpieces up to 8000 mm in length with the highest quality.

We have taken care of all the details that make a difference.

- Minimum overhangs

- Large guideways

- Wide spacing between guides

- Ballscrew and bearings’ support dimension

- Internal cooling pipes

- High-end components

Grinding program

- With the simple input of the part dimensions and the material, it generates the grinding program for you

- Easily edit complex tool and part geometries

Changeovers

Optimised solutions for the fastest changeover, including automatic grinding wheel set-up

Monitoring

- Total control in a single dashboard view

- Integration with ERP or external databases

- Measurement viewer app for results analysis and part traceability

Prior to machining

-

Measures the oversized material on the part to ensure it is machinable

-

Ensures that the part was assembled properly and the machining program is free of dimensional errors

The data it outputs

- Automatic metrological reports with dimensional and geometrical measurements

- Roundness, radial run-out, cylindricity, concentricity, coaxility, diameters, discontinuous diameters etc.

- Scanning for slender parts and back-and-forth machining

How the data is displayed

- You will be able to evaluate the behavior of the process thanks to continuous 3D visualizations

Measures and certifies in/post-process, saving machining time and avoiding scrap

Dimensional tolerances are guaranteed from the first part in IT3 up to diameter 80 mm and IT2 from 80 mm onwards

Fully integrated into DoGrind+ for easy operation and handling of the meter

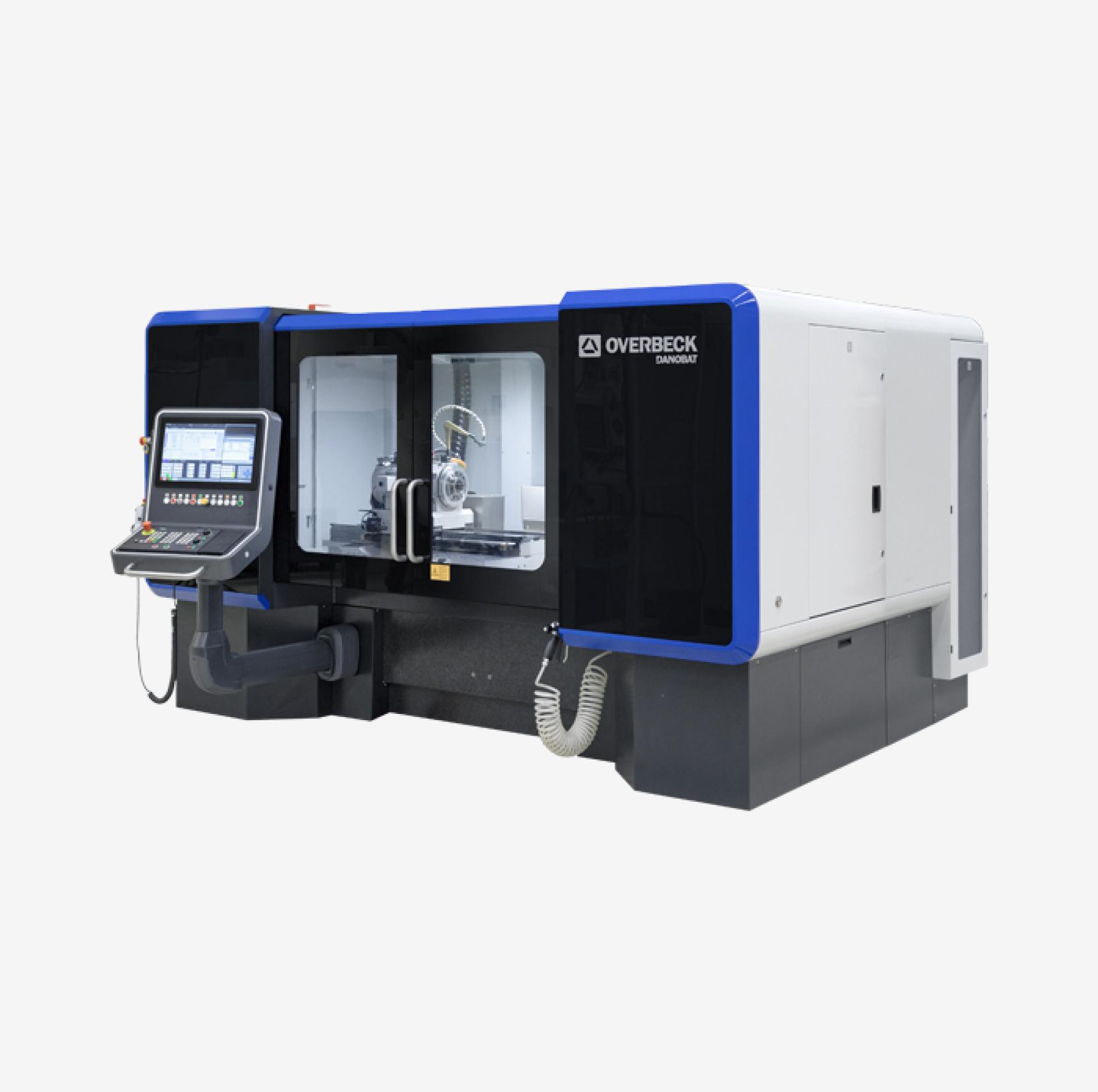

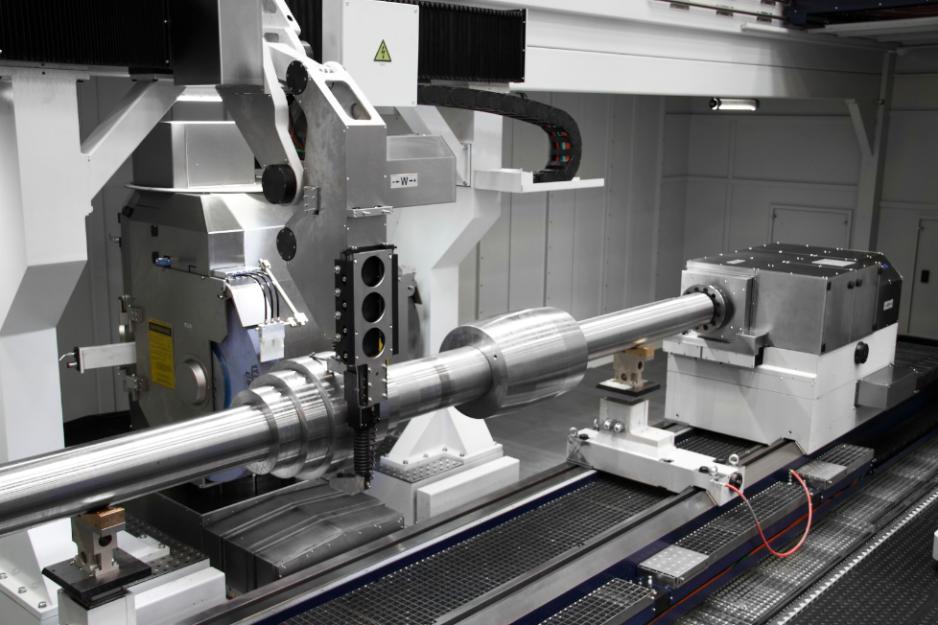

Grinding spindle heads

Mounted on proven ultra precision bearings, grease packed for life, and pre-load calculated for the maximum running accuracy and optimum stiffness under the heaviest operating conditions.

Machine structure

- Unique and rigid structure

- Made of stress-relieved pearlitic cast iron for optimum grinding accuracy

- Coolant channels for thermal stability

- Proven behaviour against vibration and thermal effects

X and Z axes

- Hydrostatic moving slides with ground and hand-scraped V and flat guideways, including antifriction coating to improve thermal stability and eliminate stick-slip effects

- Straightness of 0,002 mm over 1000 mm of length

Workhead & tailstocks

- Designed with selected materials to optimise temperature control and spindle performance

- High roundness accuracy

- Easy to connect with different clamping and driving systems

- Pneumatic lifting systems for comfortable set-ups

Swivelling B axis

- Automatic swivel, with torque motor to eliminate backlash and minimise maintenance

- Mechanical locking and pneumatic unlocking system

- Repeatiblity: ±1 µm on 650 mm radius

| WT-72 | WT-92 | WT-100 | ||

|---|---|---|---|---|

| Max. distance between centers | mm | 3000/4000/5000/6000 | 3000/4000/5000/6000/7000/8000 | 4000/5000/6000/7000/8000 |

| Max. diameter to be ground (*not available with MDM) | mm | Ø640/840 | Ø840/1040 | Ø1040/1240/1560 |

| Max. weight between centers | kg | 1500 | 5000 | 8000/15000 |

| Max. grinding wheel diameter (*not available with B-axis) | mm | Ø760/915/1060* | Ø760/915/1060/1250* | Ø915/1060/1250* |

| Wheelhead power | kW | 30/45/60 | 30/45/60 | 30/45/60 |

| Max. wheel peripheral speed | m/s | 60/120 | 60/120 | 60/120 |

| Range of MDM multi-diameter measurer | mm | 400/600 | 400/600/800 | 600/800 |

| WT-72 | WT-92 | WT-100 | ||

|---|---|---|---|---|

| Max. distance between centers | in | 118/157/196/236 | 118/157/196/236/275/315 | 157/196/236/275/315 |

| Max. diameter to be ground (*not available with MDM) | in | Ø25.2/33.1 | Ø33.1/41 | Ø41/48.8/61.4 |

| Max. weight between centers | lb | 3307 | 11023 | 17637/33069 |

| Max. grinding wheel diameter (*not available with B-axis) | in | Ø30/36/40* | Ø30/36/40/50* | Ø30/40/50* |

| Wheelhead power | hp | 40.2/60.3/80.4 | 40.2/60.3/80.4 | 40.2/60.3/80.4 |

| Max. wheel peripheral speed | sfpm | 11811/23622 | 11811/23622 | 11811/23622 |

| Range of MDM multi-diameter measurer | in | 15.7/23.6 | 15.7/23.6/31.5 | 23.6/31.5 |

Gearbox shafts

Extrusion screw

Printing and packaging rolls

Electric motor shaft

Railway axle

- We can exchange your damaged or worn spindle for one we have in stock to eliminate downtime

- Remote machine diagnosis: Keep your machine connected and analyse the vibration threshold of your machine spindles and the condition of your ball screws (circularity tests, backlash measurements, etc.)

- Updated electronic & mechanical upgrade options to improve your OEE, reduce maintenance times, and avoid obsolescence

- Customised maintenance plans based on your production needs: laser interferometry tests, measuring equipment calibration and much more