Email us

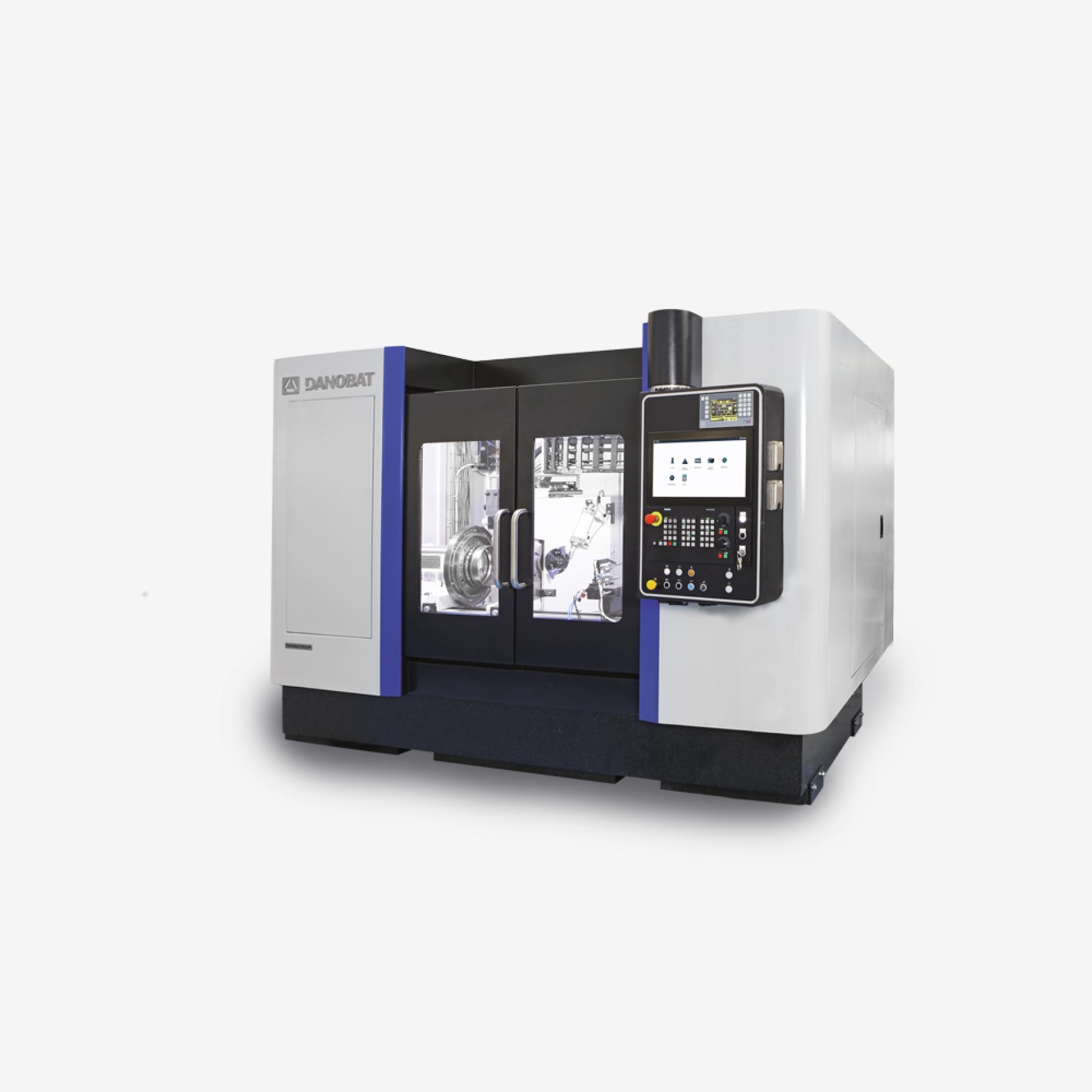

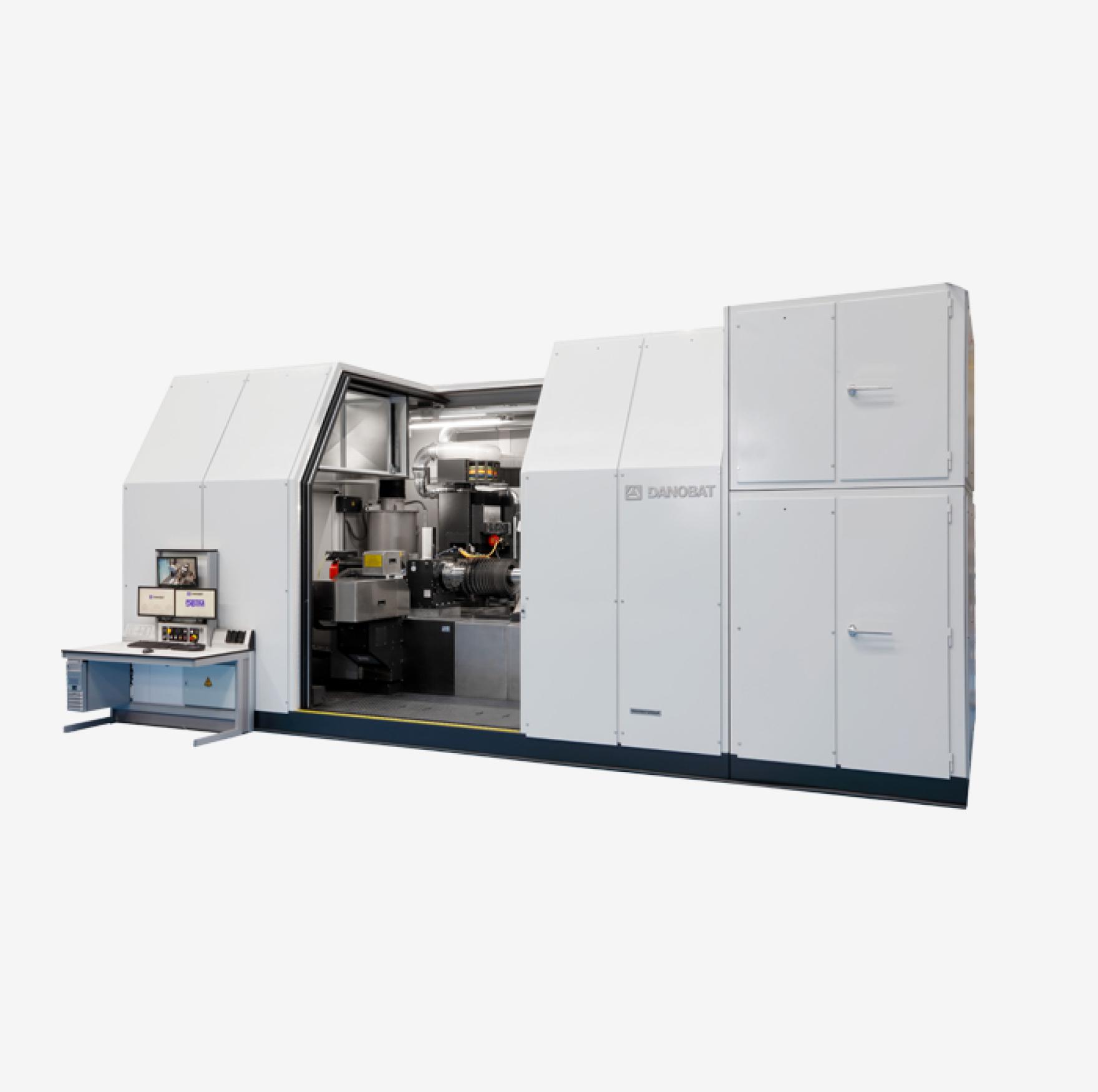

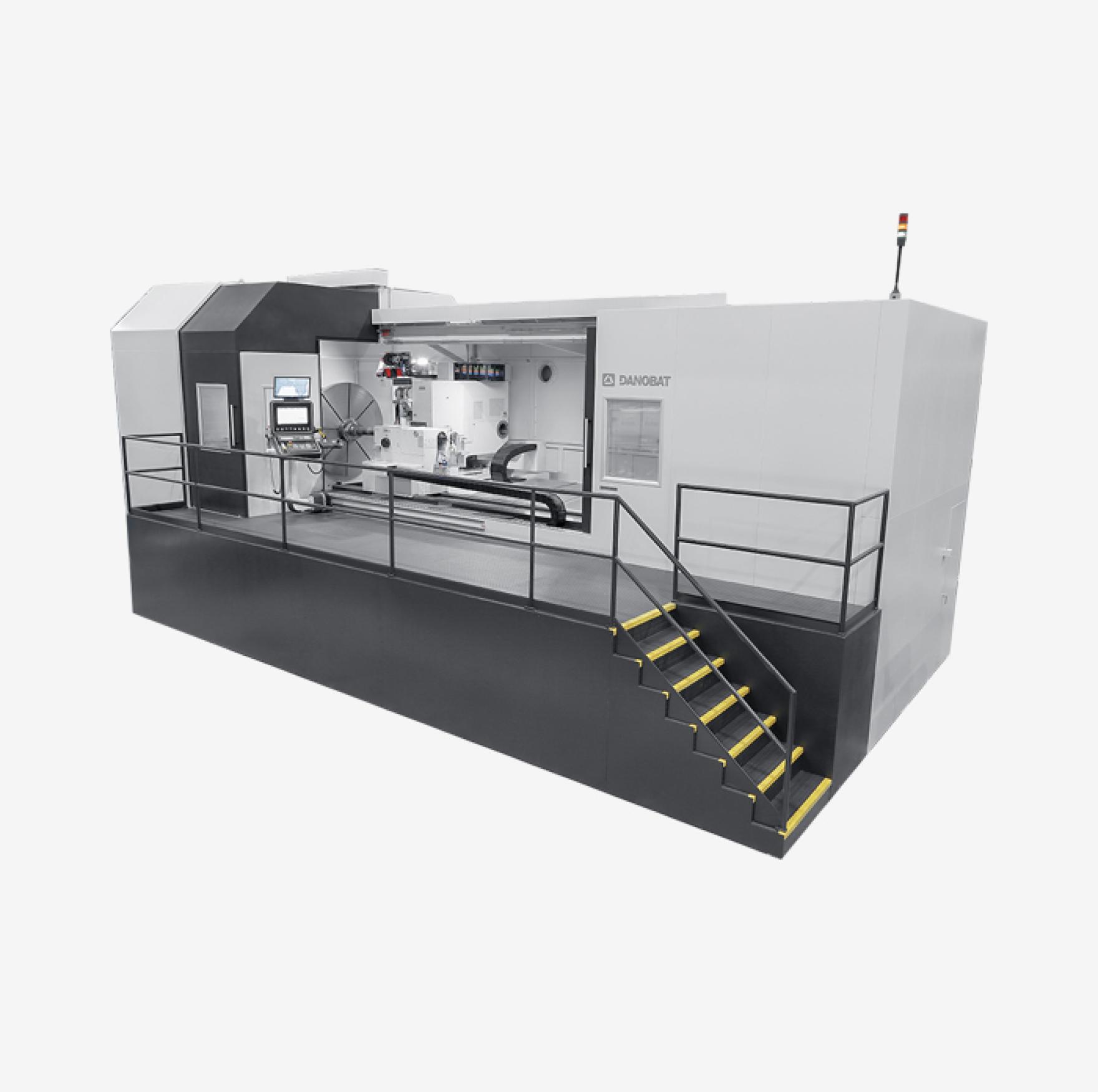

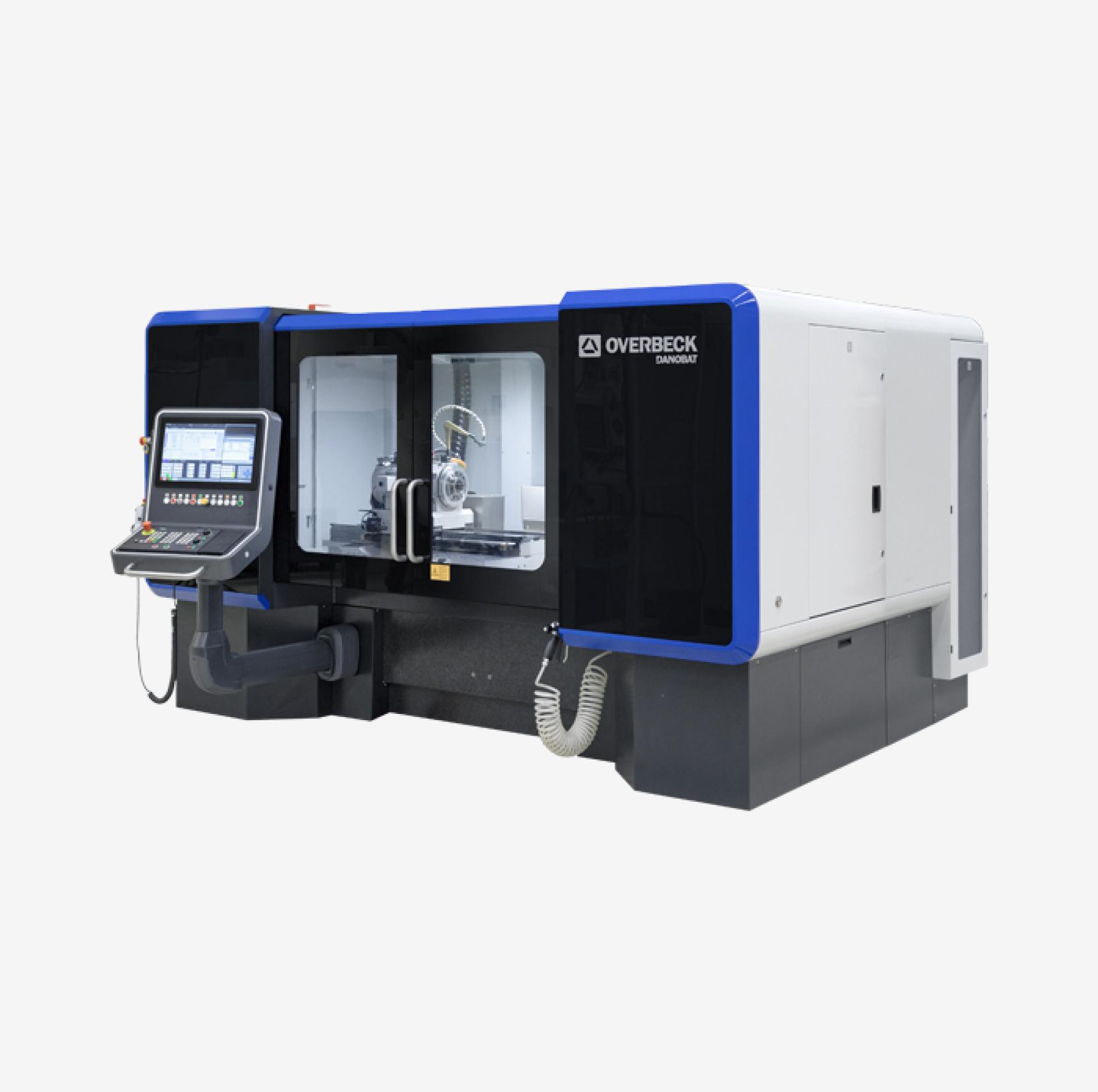

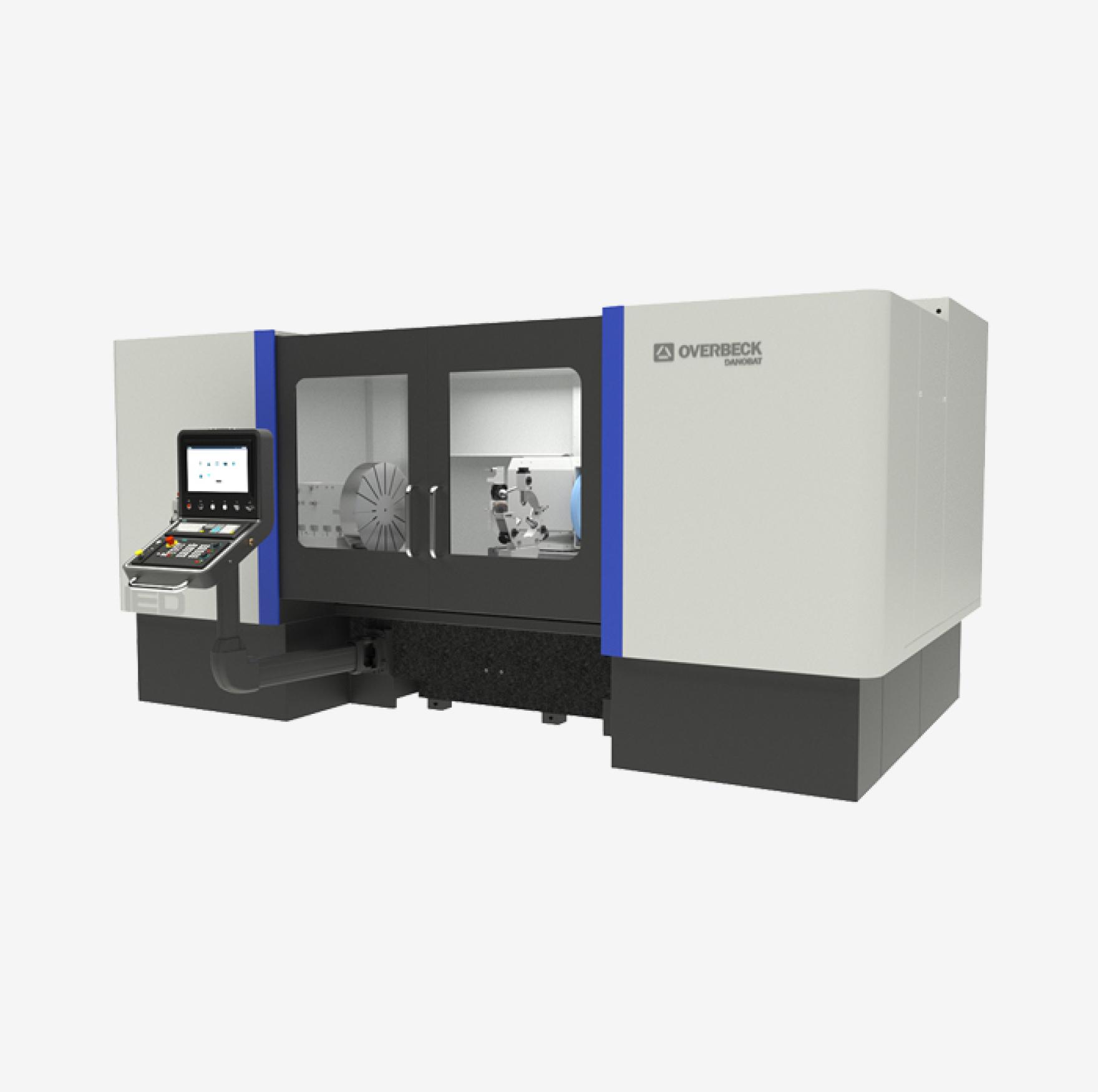

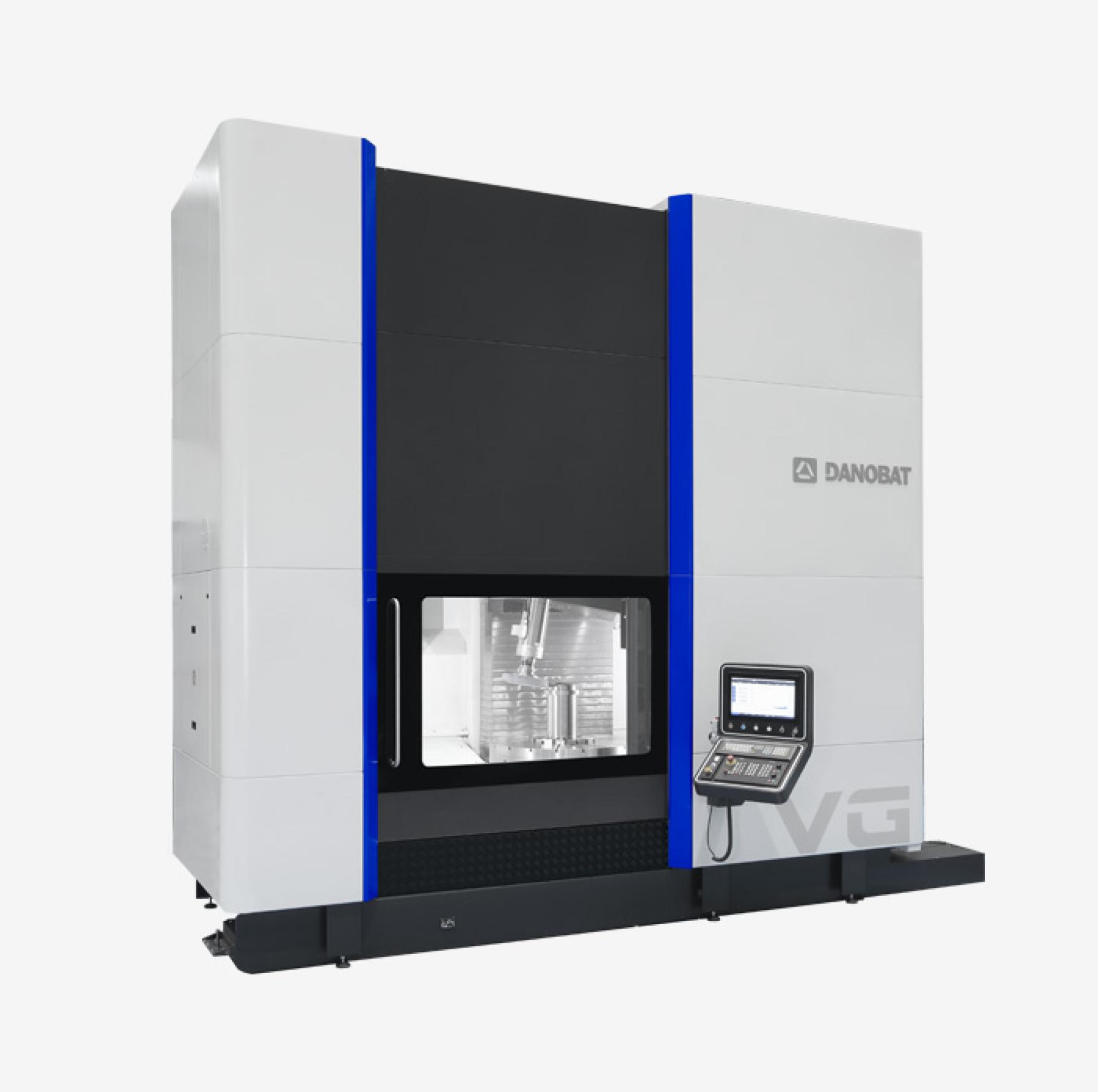

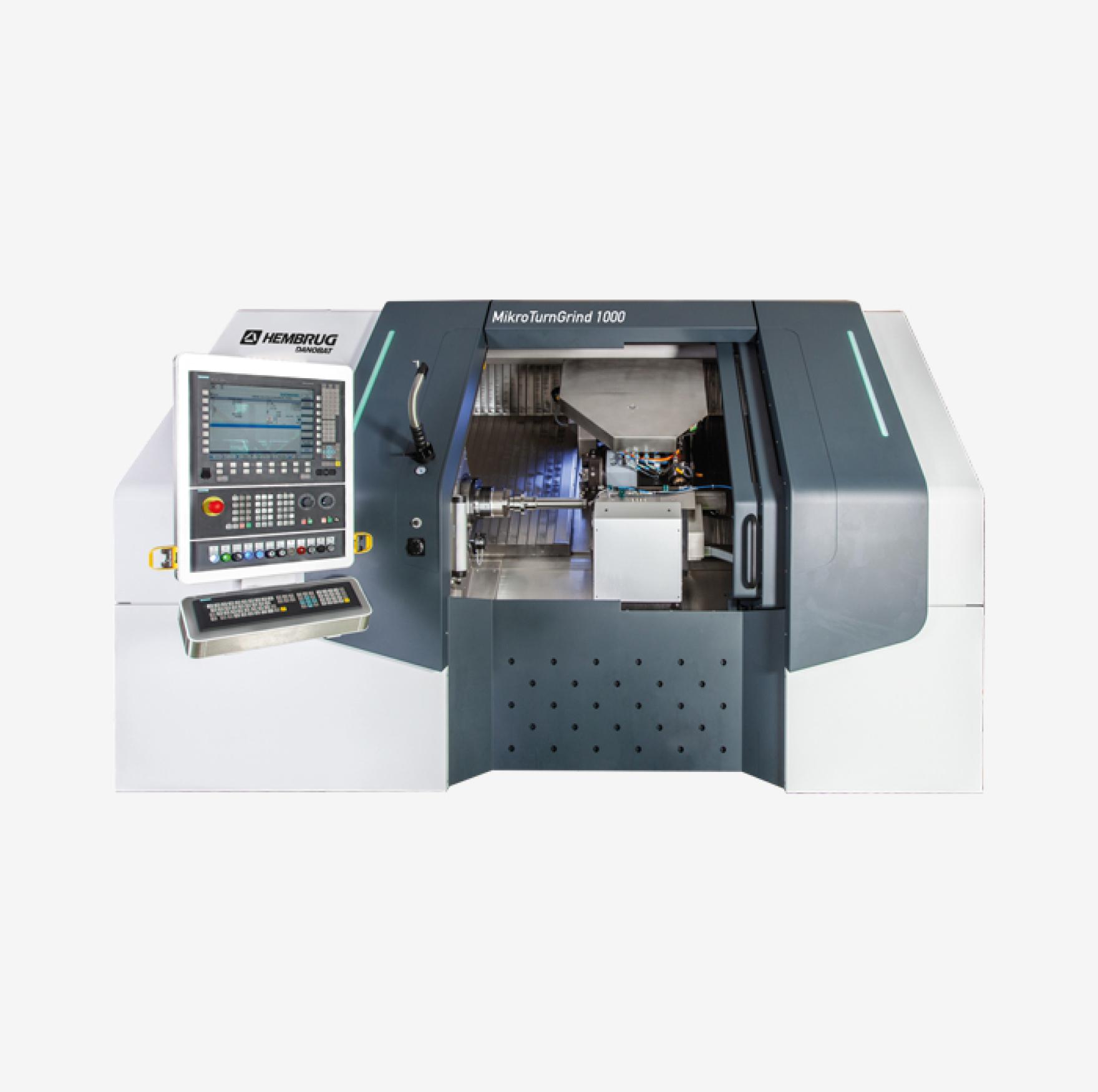

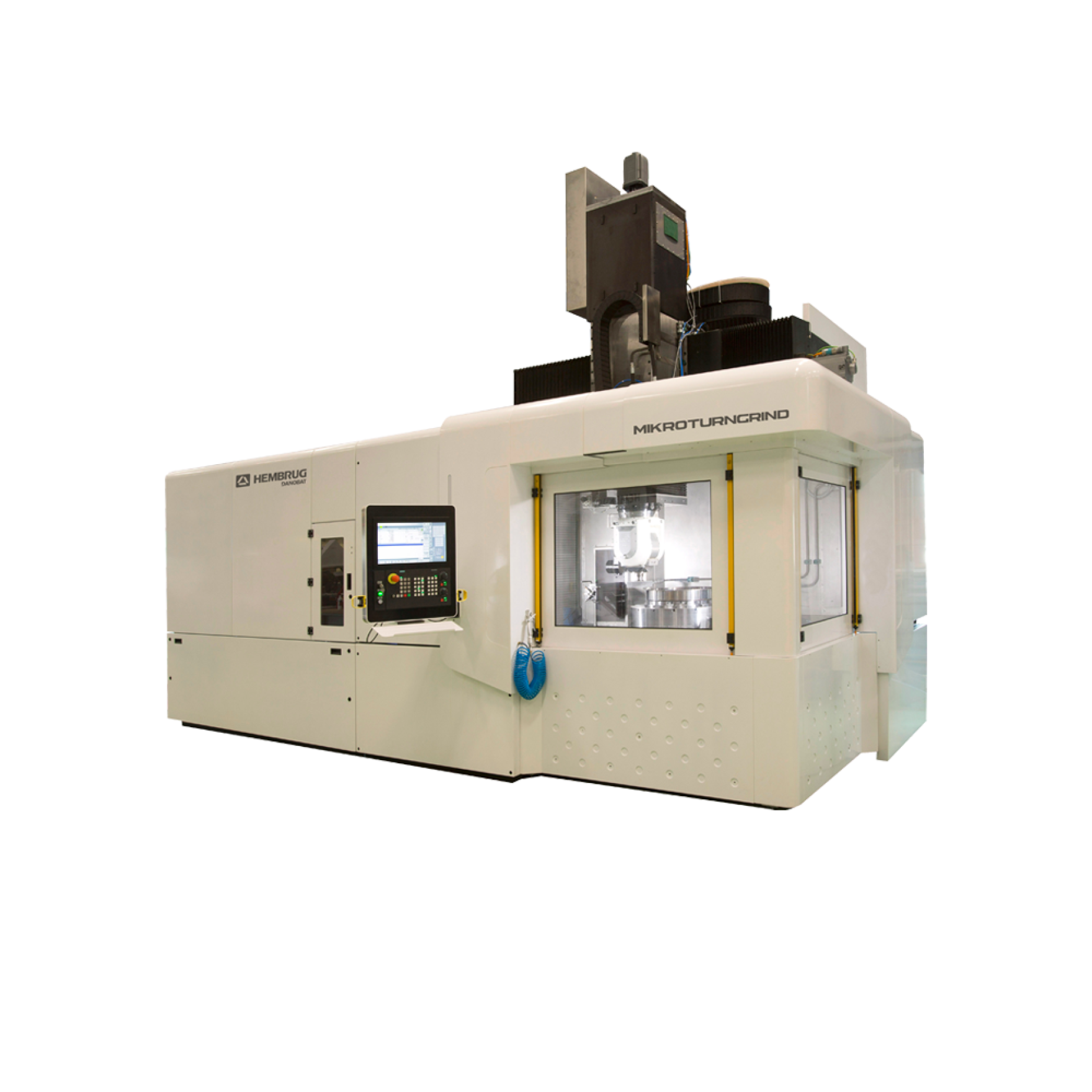

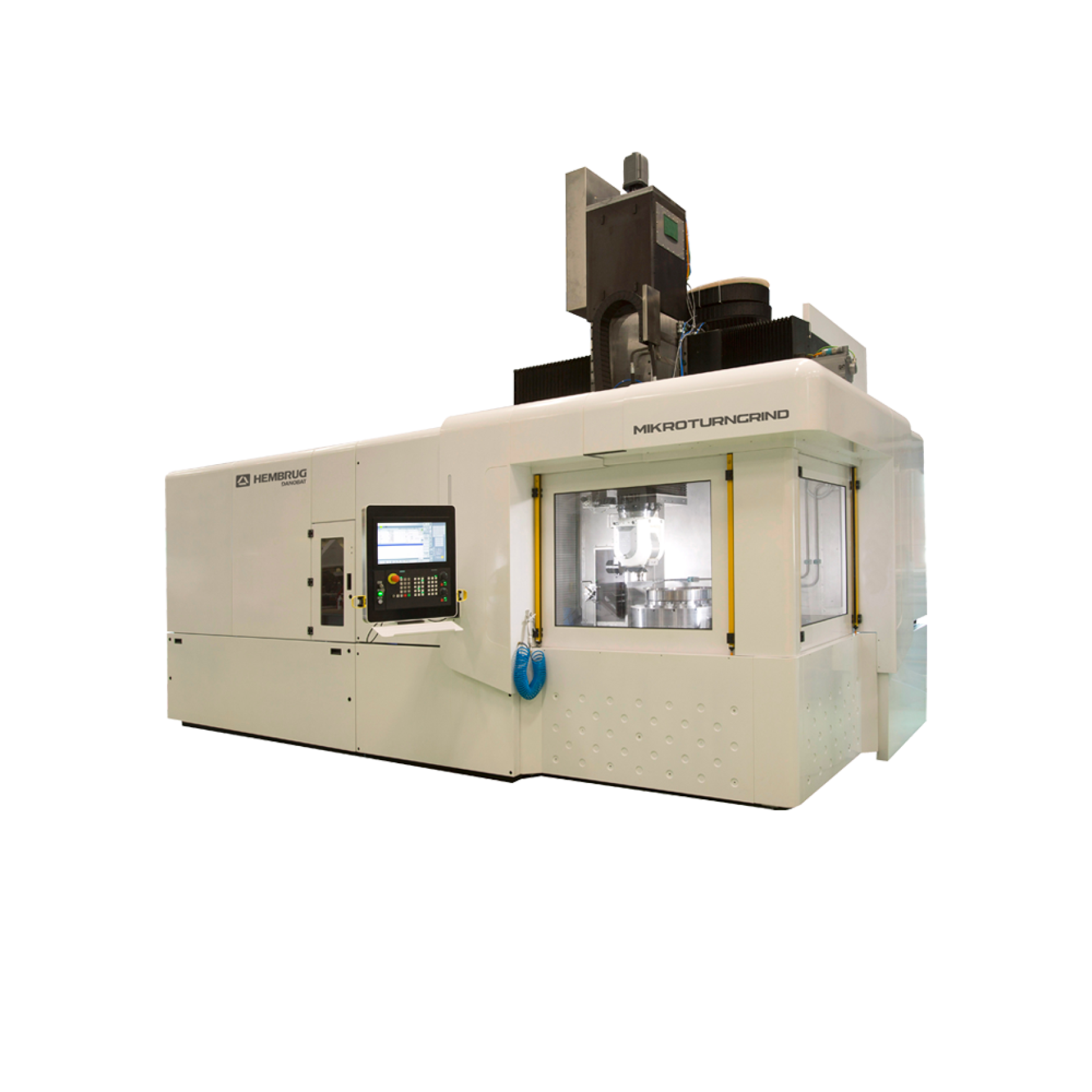

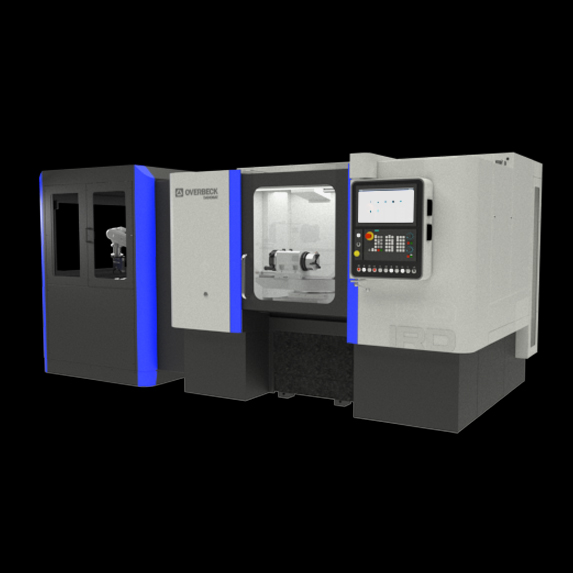

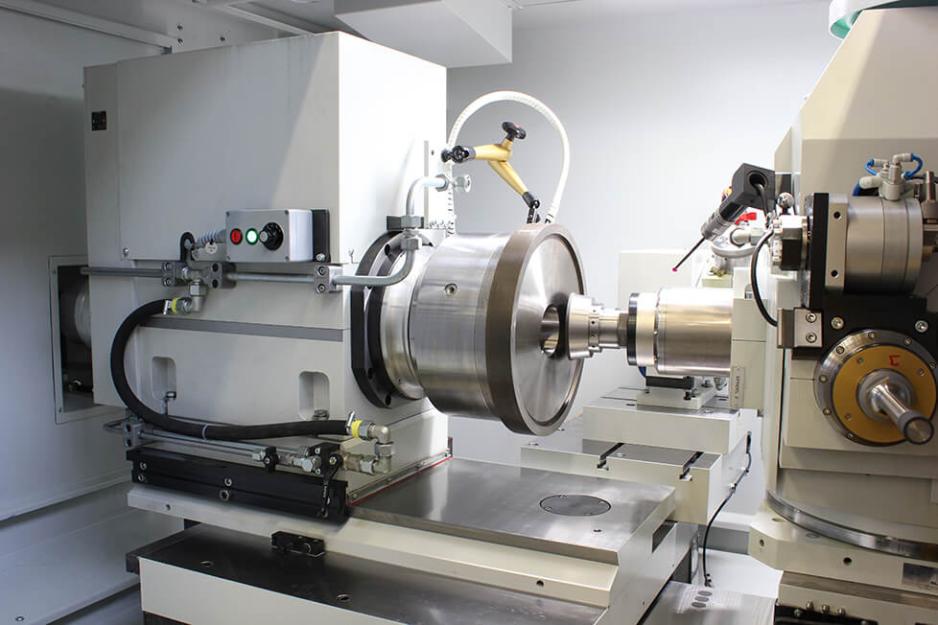

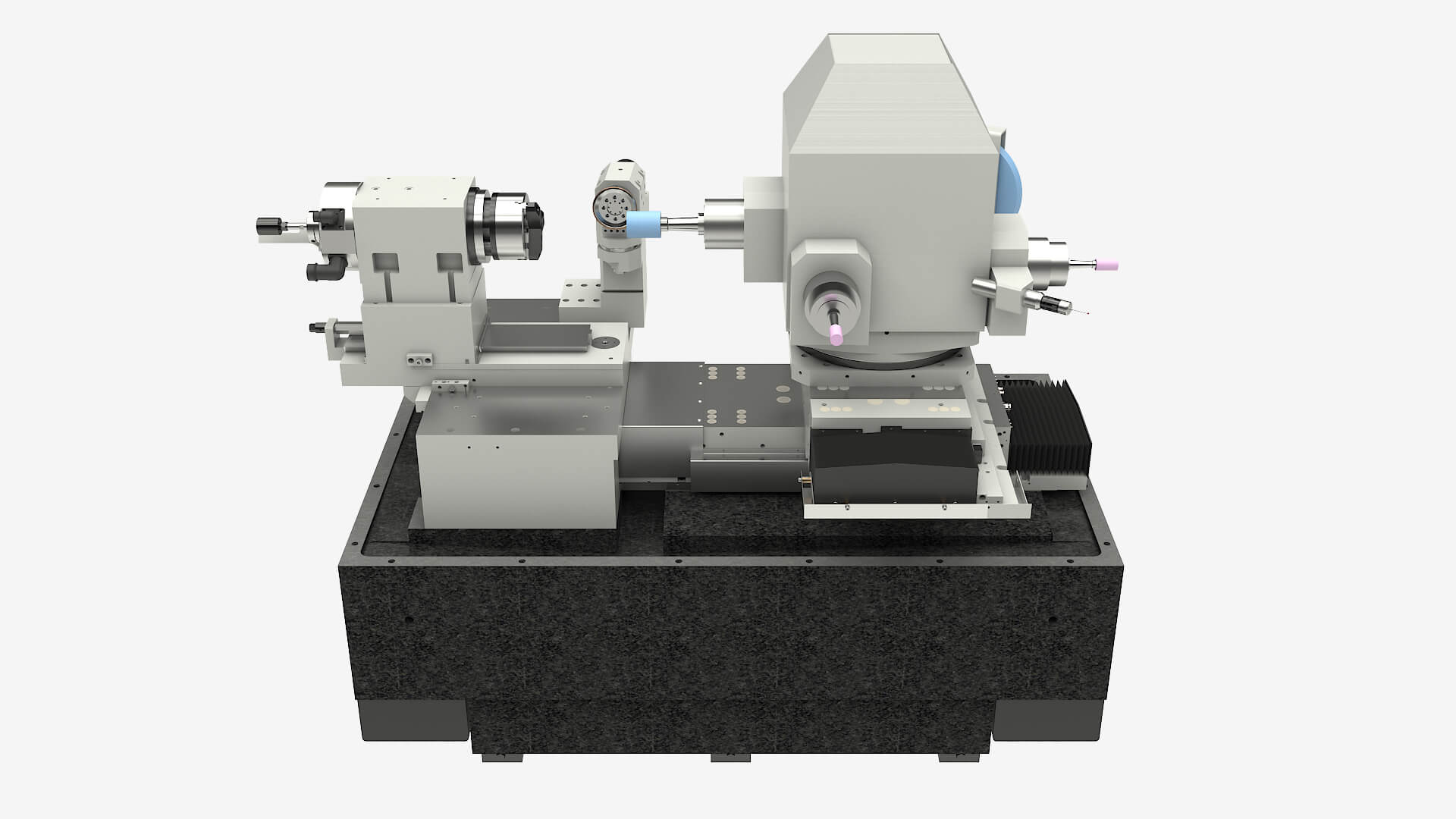

INTERNAL, EXTERNAL AND FACE GRINDING MACHINE

Internal, external and face grinding machine that offers high efficiency without compromising versatility.

Built to last for 24/7 production.

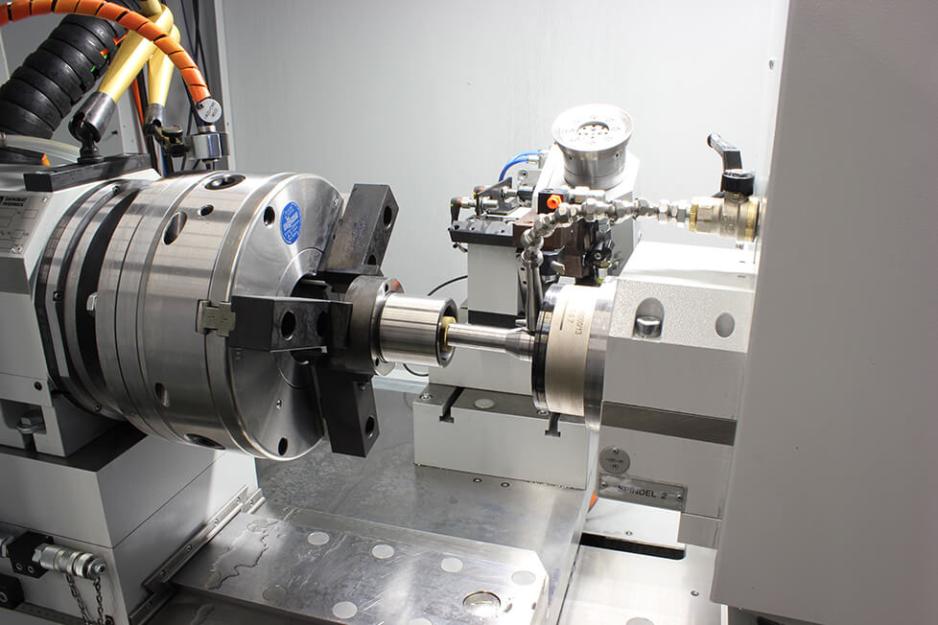

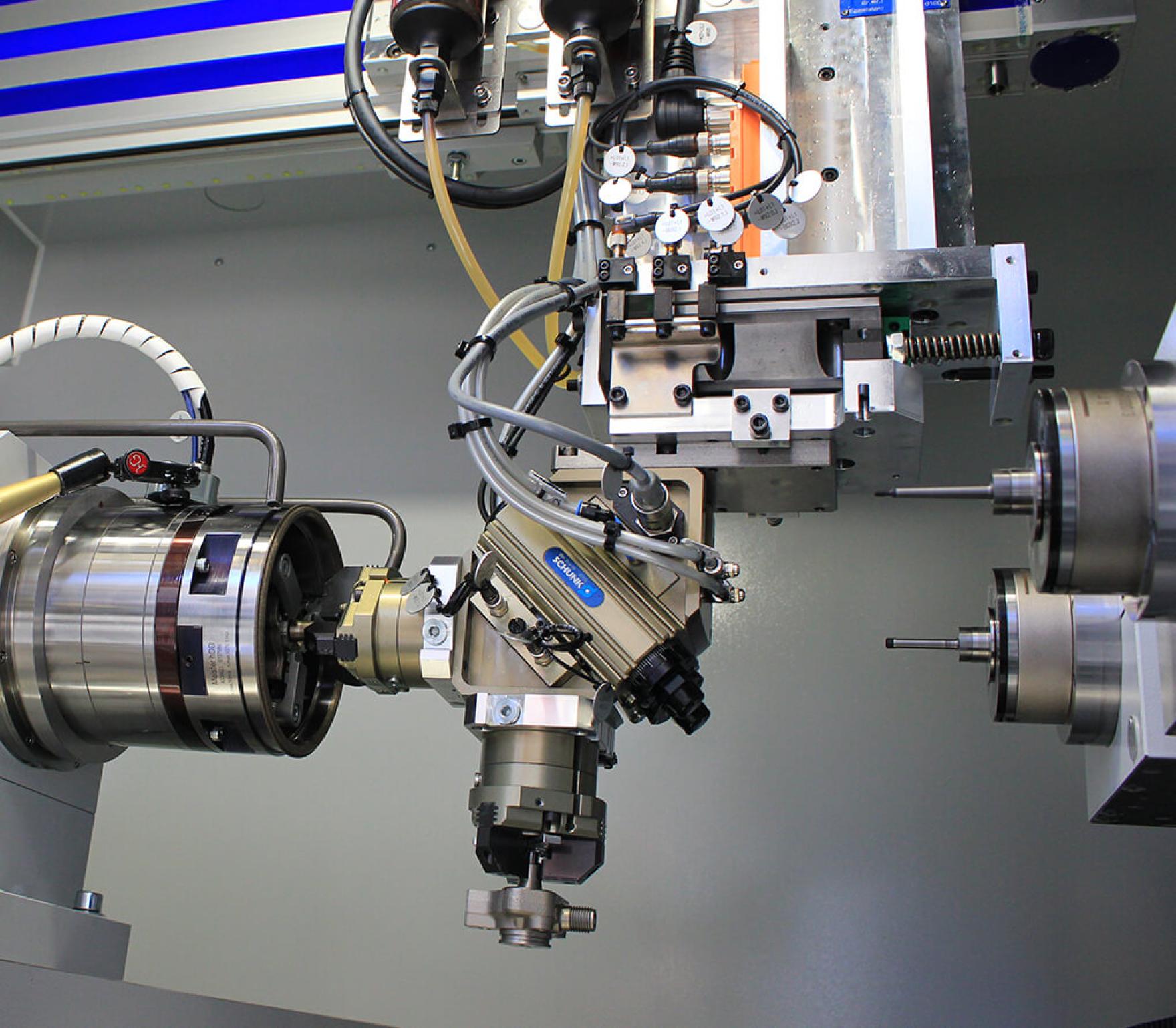

- Wide range of workheads and grinding spindles, plus clamping, dressing and measuring systems

- Special spindle configurations for the tightest tolerances and fastest cycle times: one, two or even three spindles in parallel

Natural granite base

Machine bed made of natural granite, the optimal material for achieving the highest accuracy.

Linear motors

Linear motors deliver highly dynamic transmission of power. The technology achieves fast and precise movements that guarantee maximum productivity and quality.

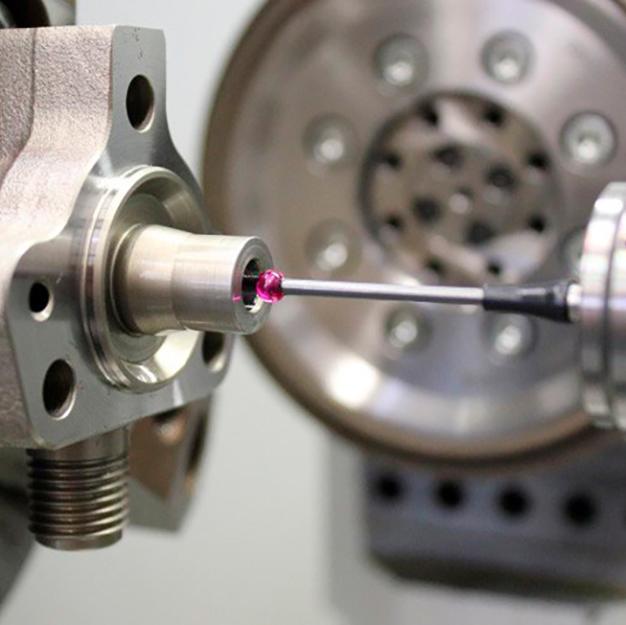

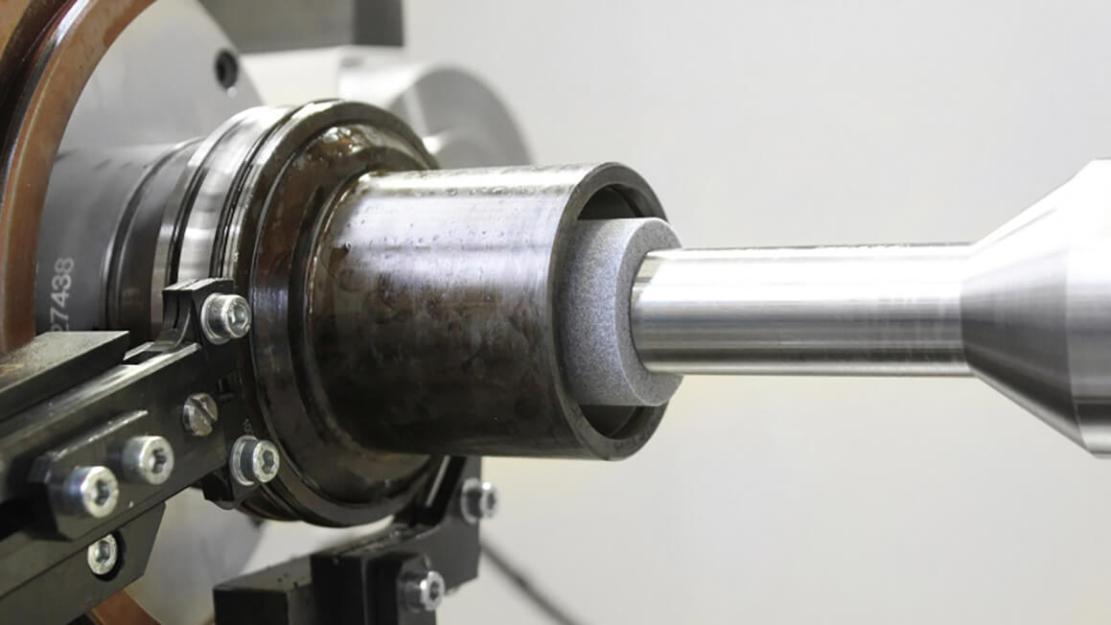

Workhead

Carefully built in our own facilities with high quality components for long life. All this helps to ensure that the workpieces have the optimum quality you are looking for.

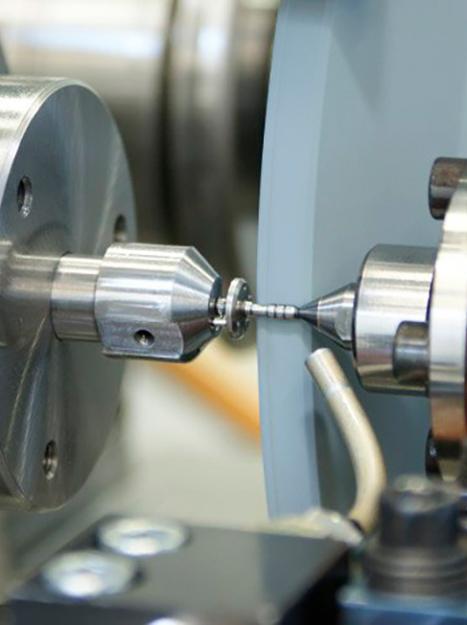

Grinding spindles

High quality spindles with high precision bearings with air/oil or lifetime lubrication.

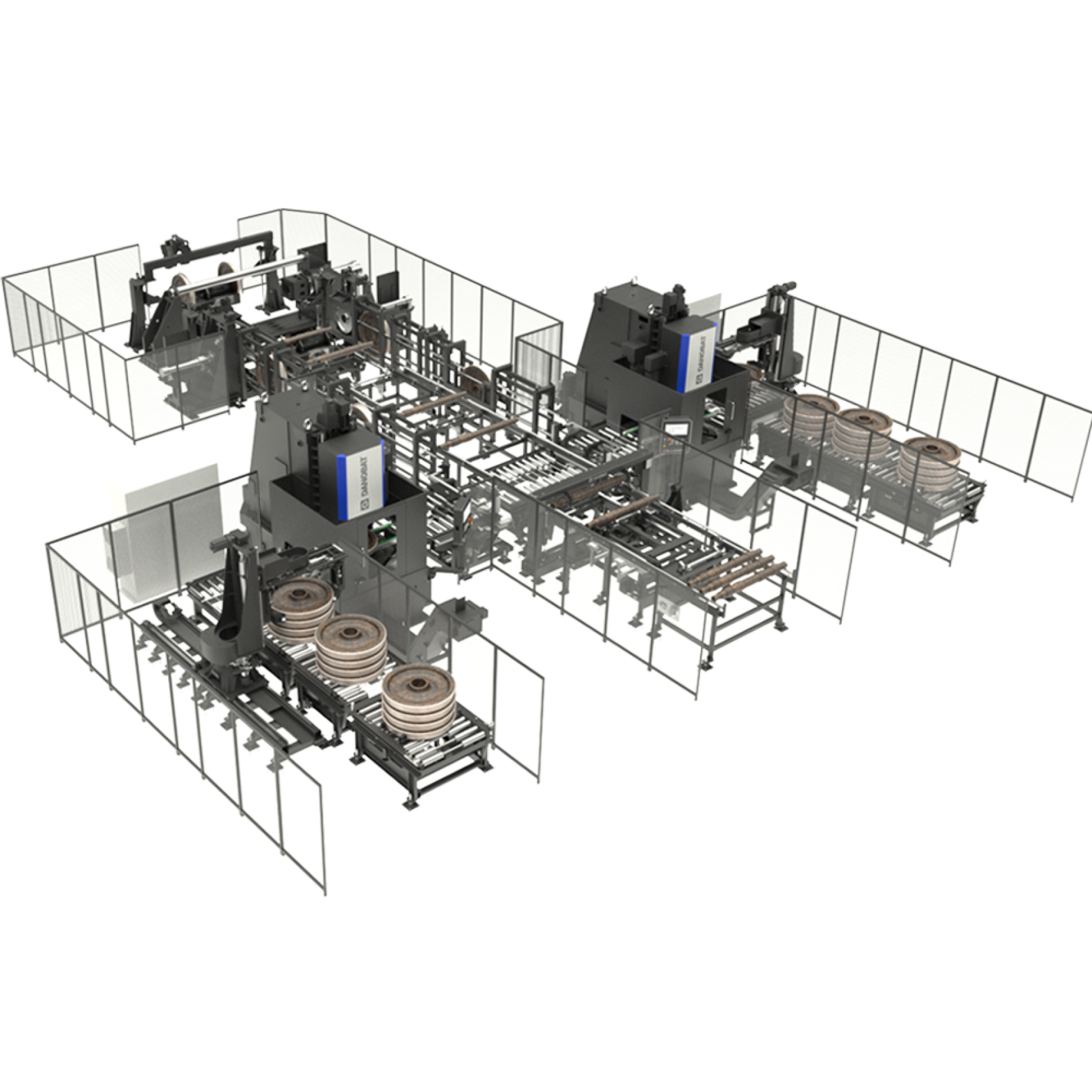

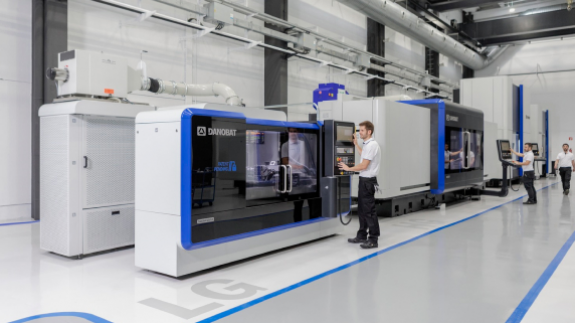

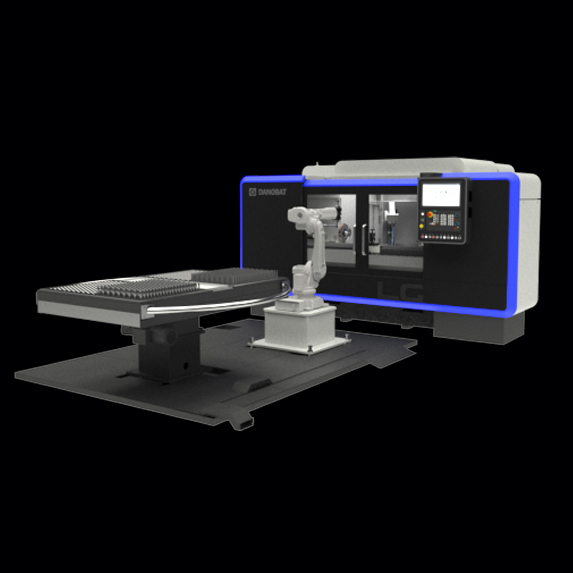

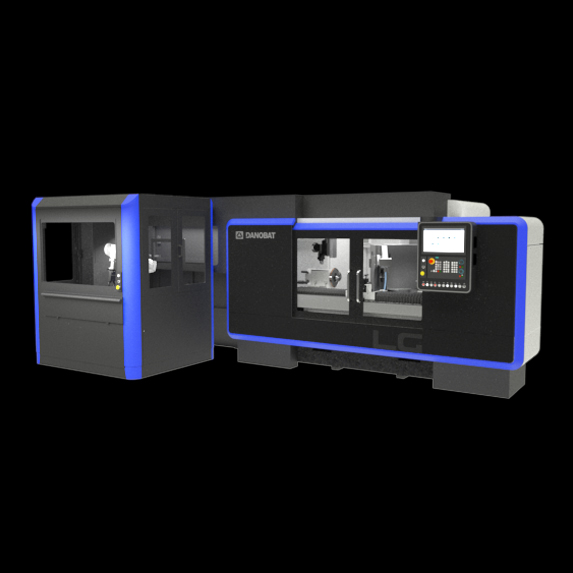

We can offer you a machine including (un)loading systems, feeding or storage systems, and auxiliary stations.

| ID-200 | ID-400 | ||

|---|---|---|---|

| Max. internal grinding diameter | mm | 100 | 200 |

| Max. internal grinding length | mm | 100 | 200 |

| Max. workpiece swing diameter | mm | 215 | 560 |

| Max. workpiece length incl. clamping system | mm | 200 | 400 |

| Max. workpiece weight incl. clamping system | kg/Nm | 40/45 | 80/100 // 180/300 |

| X and Z axis stroke | mm | 400/200 | 425/475 |

| ID-200 | ID-400 | ||

|---|---|---|---|

| Max. internal grinding diameter | in | 3.9 | 7.8 |

| Max. internal grinding length | in | 3.9 | 7.8 |

| Max. workpiece swing diameter | in | 8.4 | 22 |

| Max. workpiece length incl. clamping system | in | 7.8 | 15.7 |

| Max. workpiece weight incl. clamping system | lb/ft-lb | 88/33 | 175/70//400/220 |

| X and Z axis stroke | in | 15.7/7.8 | 15.7/7.8 |

Gears

Guiding bush

Inner & outer ring

Eccentric pump shaft

Gear pump shaft

Axial motor shaft

Piston for radial & axial motors

Seat housing

Machine tool spindle shaft

Machine tool spindle housing

Hip joint

- Customised maintenance plans depending on production needs, including laser interferometry tests, measuring equipment calibration...

- We do machining tests on your parts to find the best machining solution for you