Email us

Knowledge

Specialised articles, exclusive content, videos & case studies

Knowledge

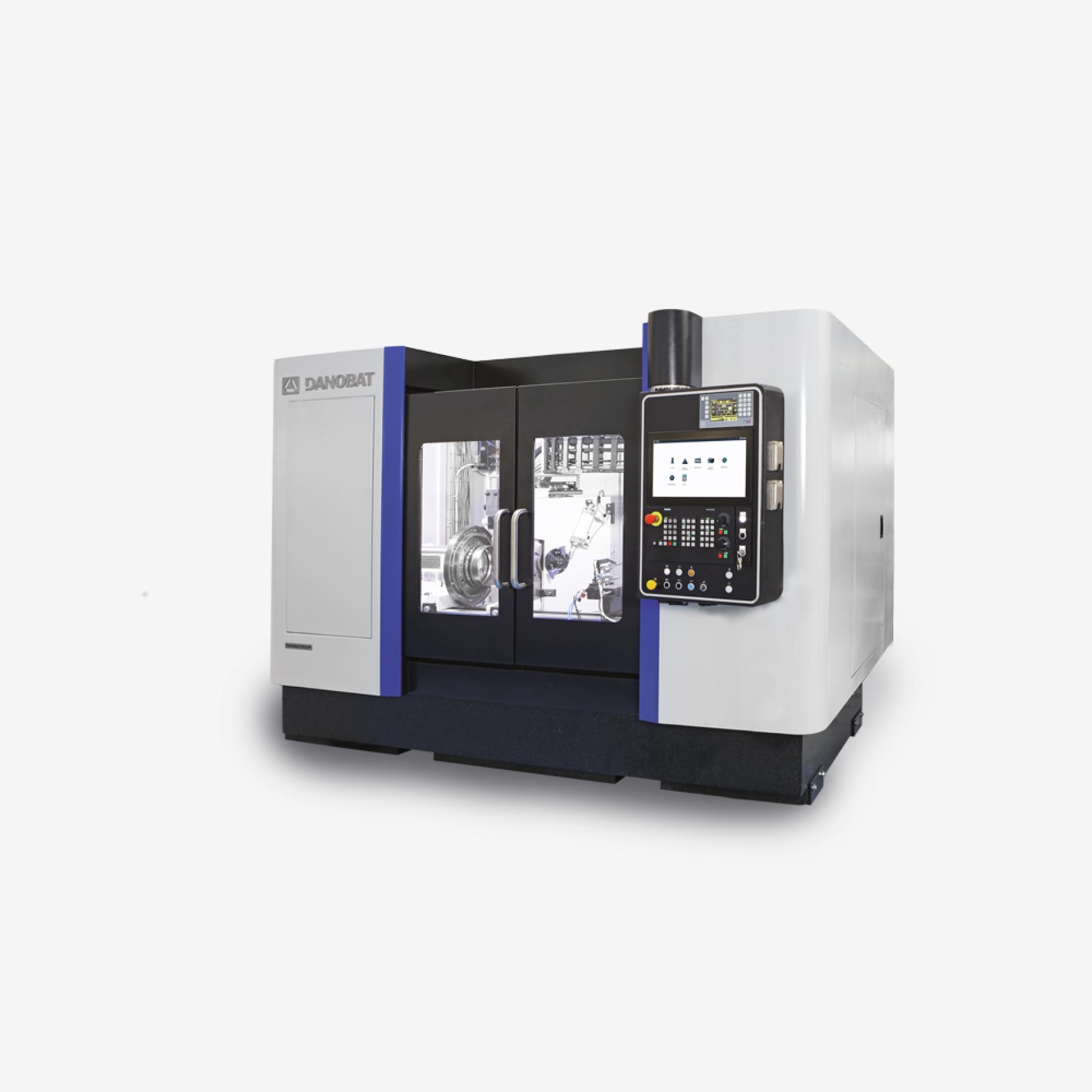

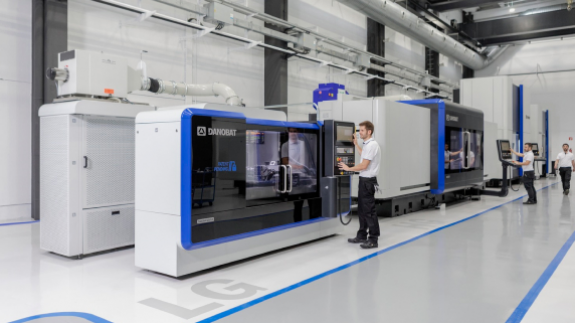

Download this e-mobility catalogue to discover different high production, but yet very flexible grinding machines for specific e-mobility applications: EV reducer shafts, different dimencion EV rotor shafts, battery dies...

Discover the most important elements of a CNC machine that buyers should consider when evaluating machining solutions.

Unfortunately, it’s never that simple and there are many variables to consider before arriving at a final solution. In this article, we take a closer look at these factors.

This whitepaper focuses on analysing the benefits that the use of granite brings to the machine’s performance compared to other types of materials.

Watch this video to discover some application examples where hydrostatic technology is used and find out the advantages of applying it in a machine tool.

One of our customers that machines high precision parts for companies such as Siemens Gamesa shows the capabilities of new generation CG in action.

Download the video to get more information about the market's different type of in-process measuring systems. In-process measurement is the big topic covered.

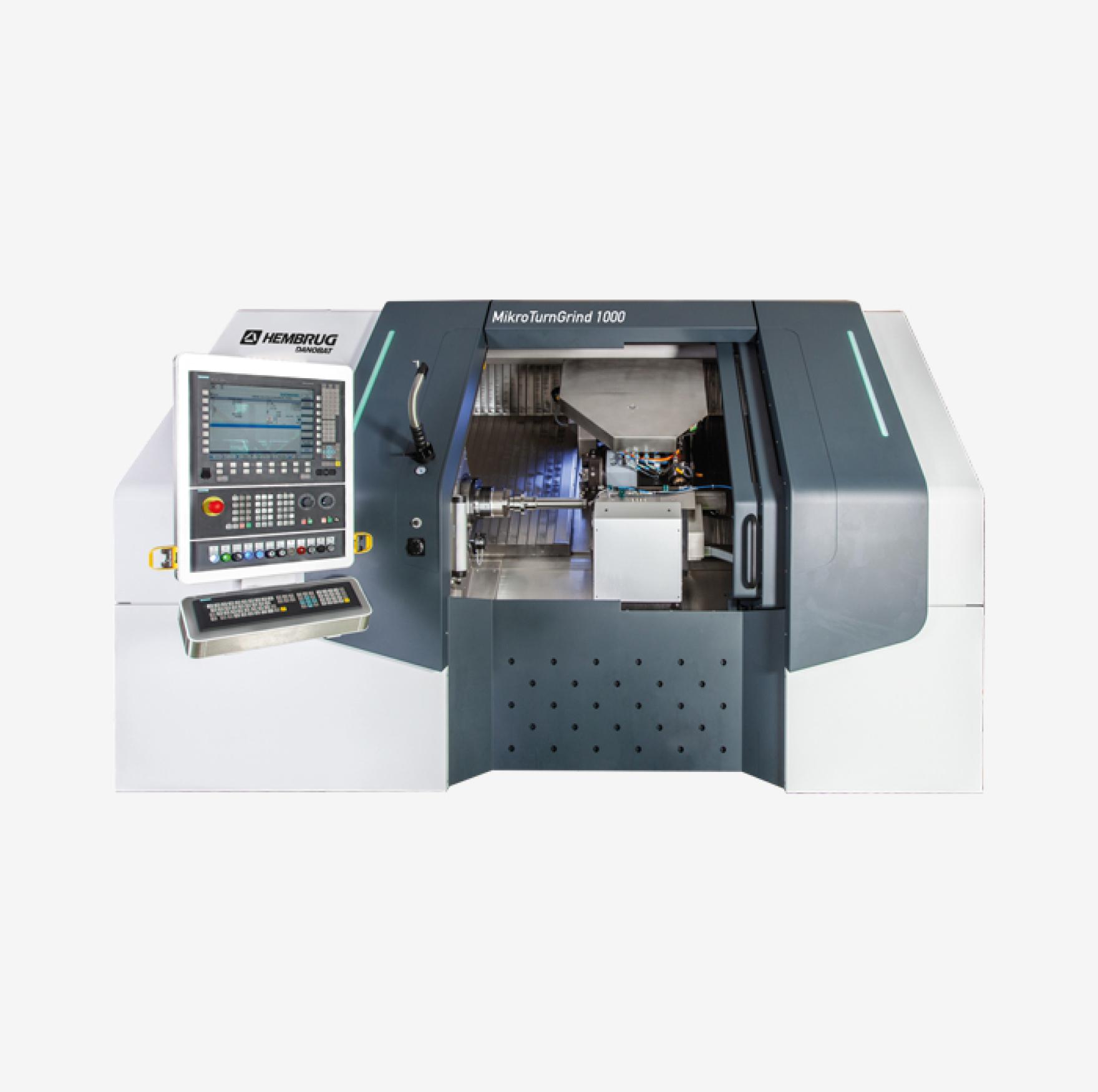

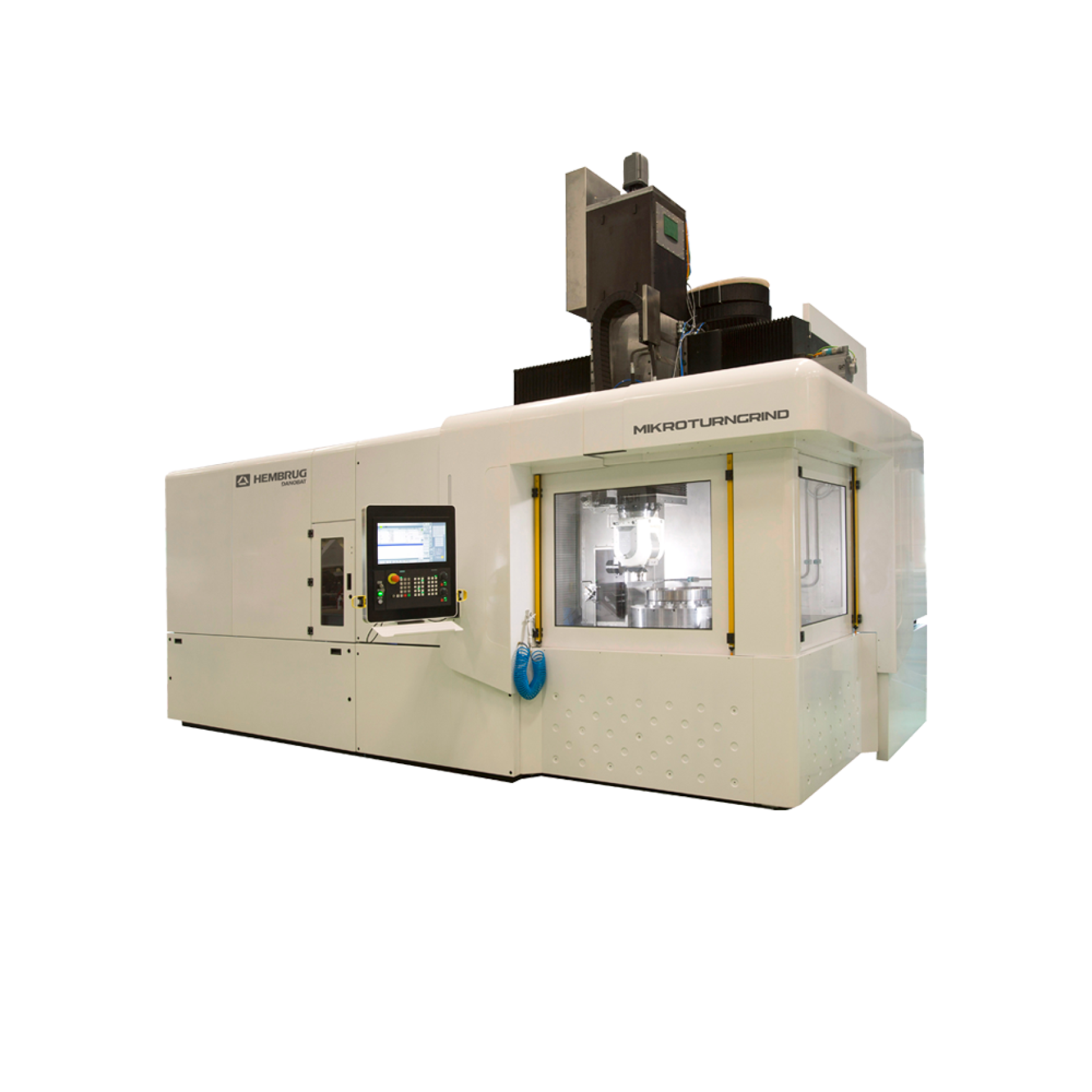

See the video below to better know the capabilities of hybrid solutions and check if you can benefit from a both grinding and hard turning machine.

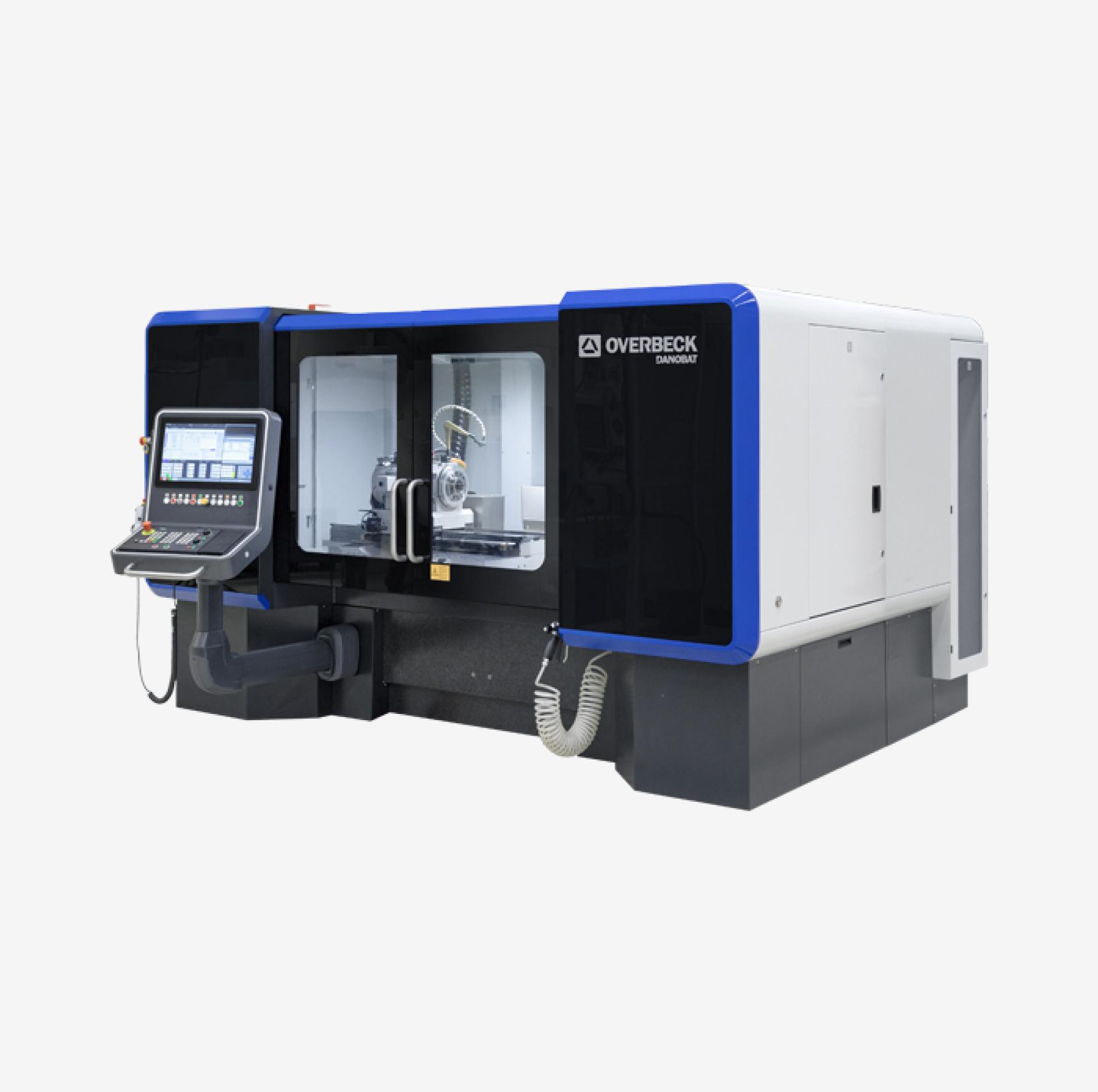

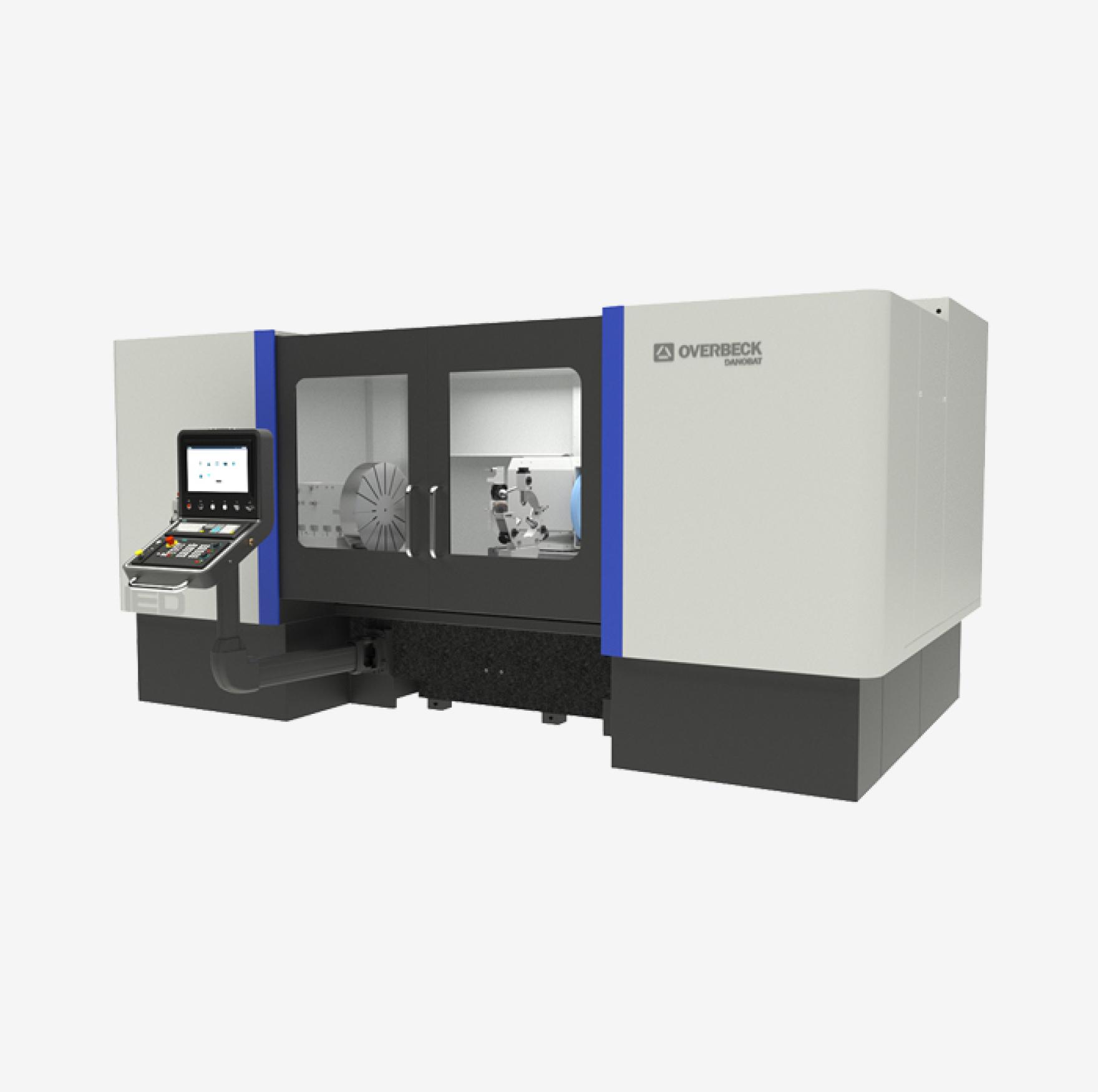

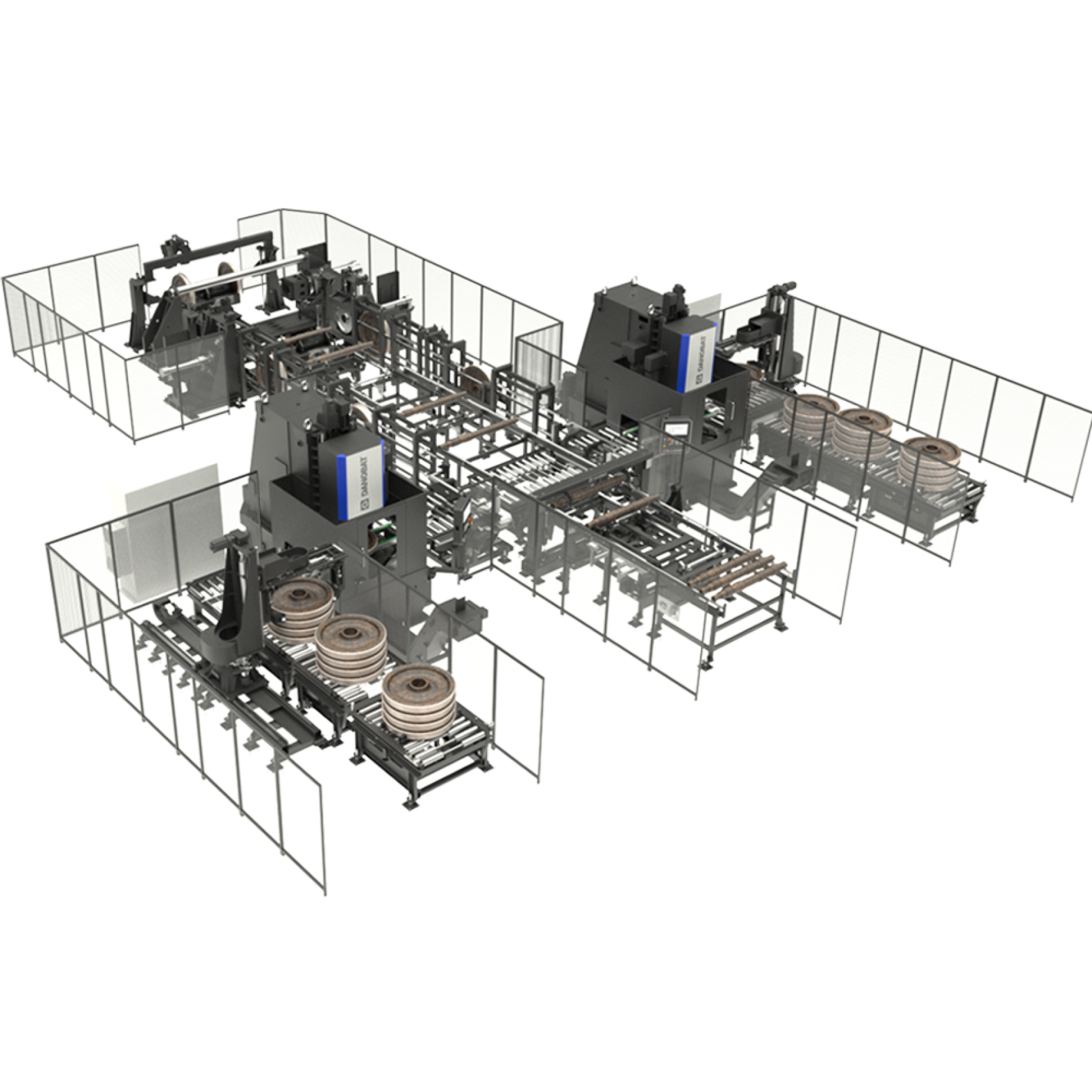

We provide high precision and cost-effective grinding and hard turning solutions for a wide range of canning parts: from ironing and redraw dies, to knock-outs and punches. Want to know more about our solutions?

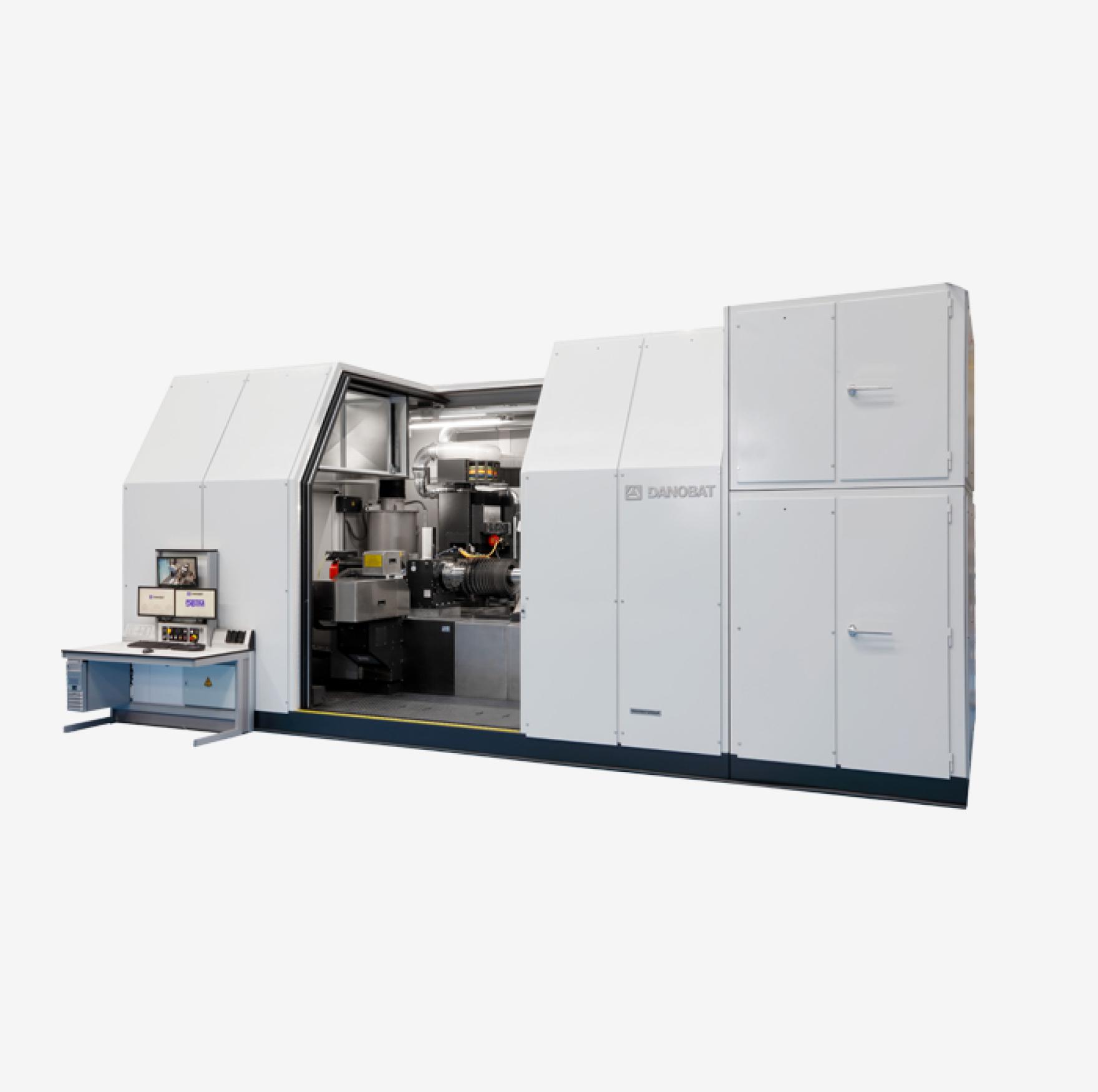

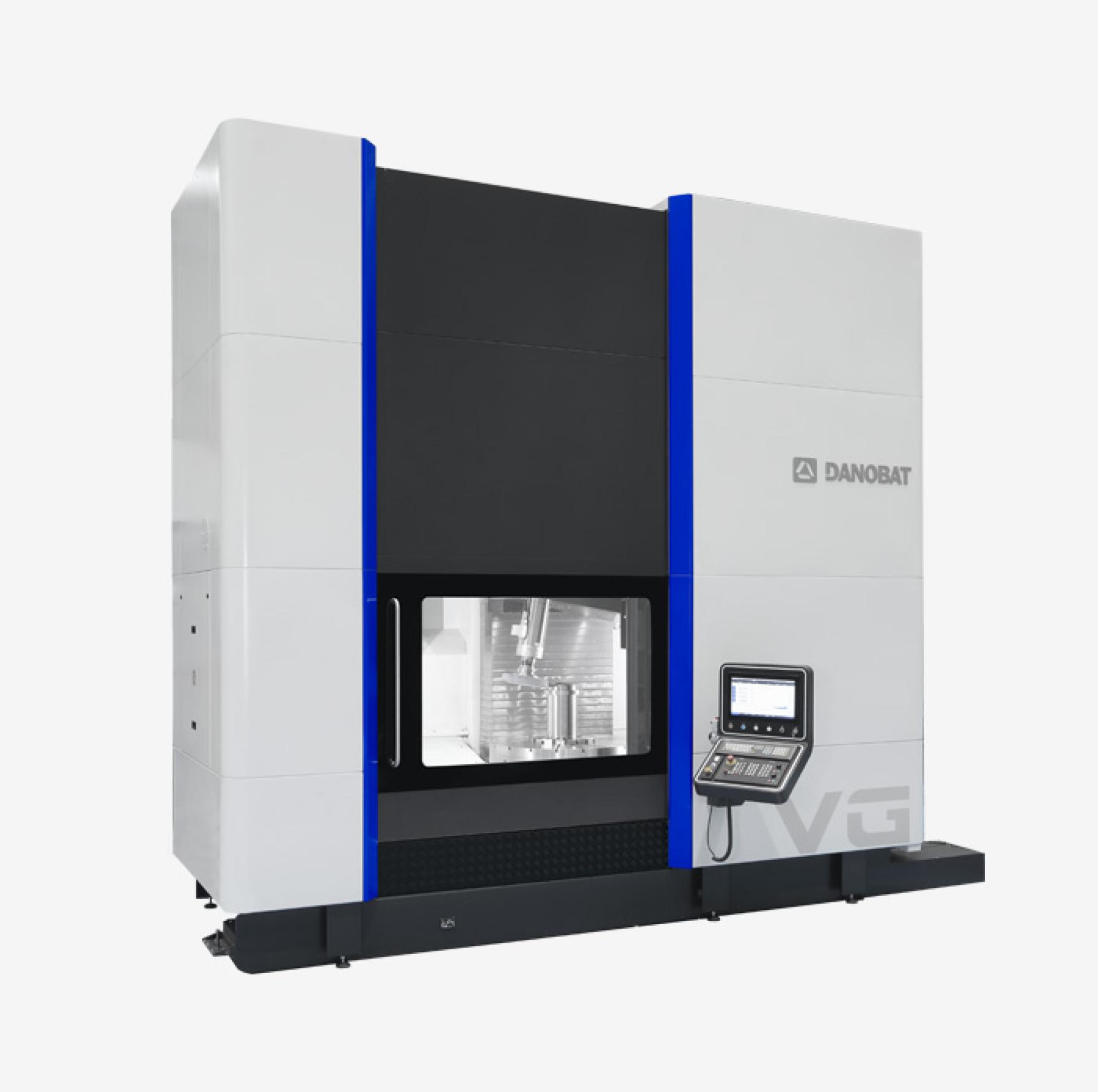

The wind industry is under enormous pressure to reduce cost per MWh. They need to improve turbine designs, raise performance, and increase reliability – all while reducing maintenance costs. We have a solution for that.

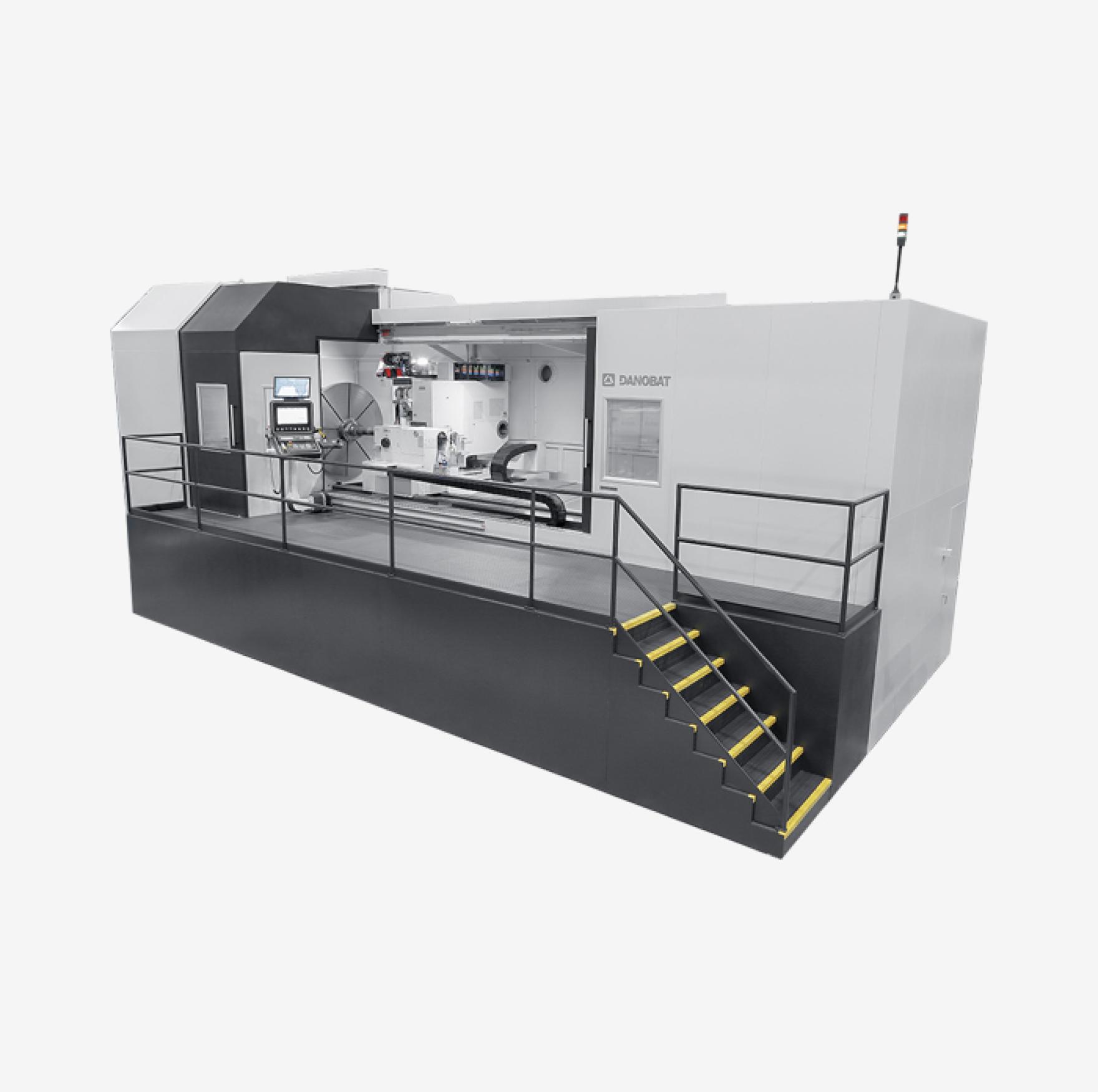

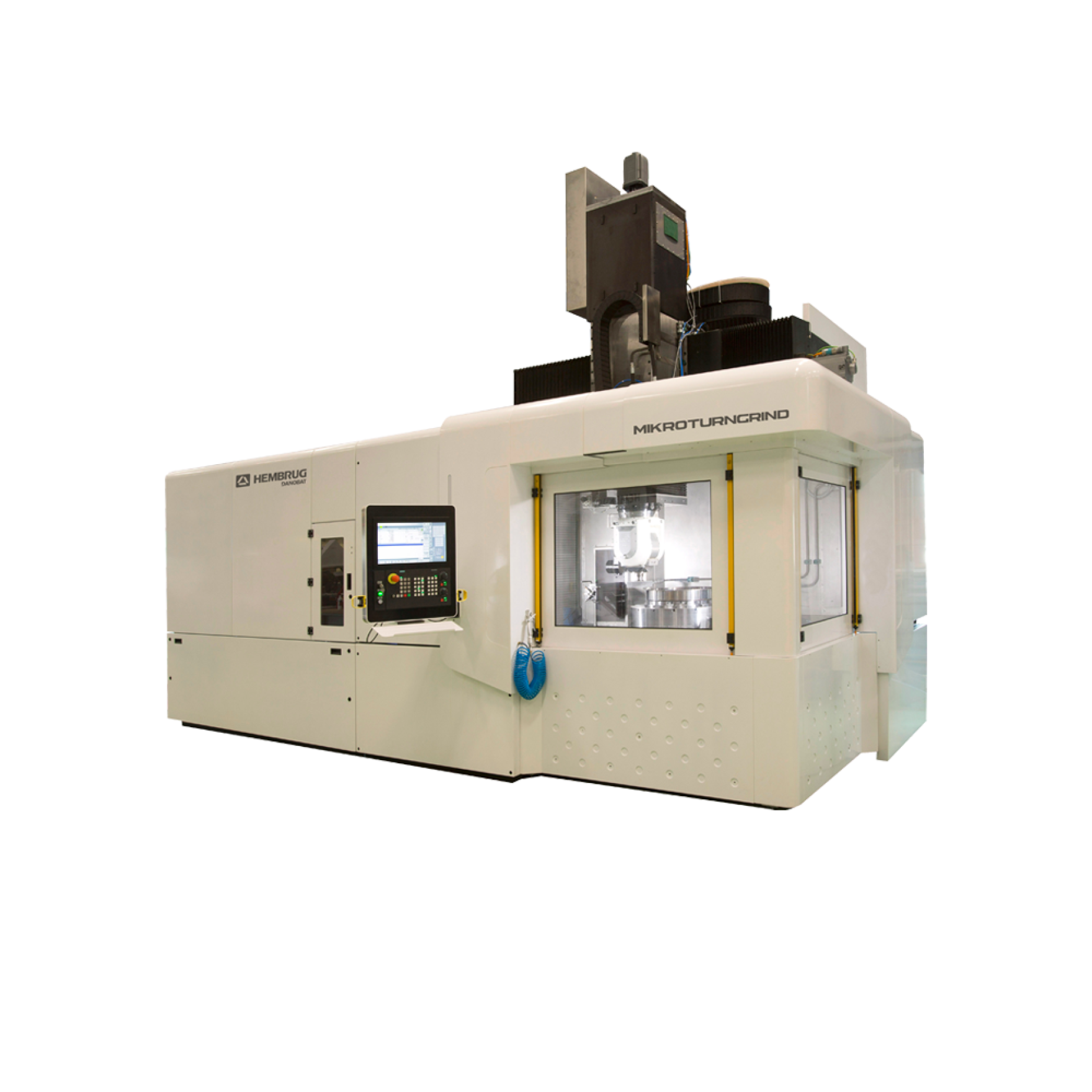

Do you need to hold diameter, roundness, and TIR to within 2 µm in large parts that weight up to 500 kg? If so, the ILD may be the solution you are looking for.

Are you looking for optimising the maintenance tasks in your wheel shop? If you are interested in how to increase the efficiency of railway wheelset maintenance shops, watch the video below.

Keep me up to date