Email us

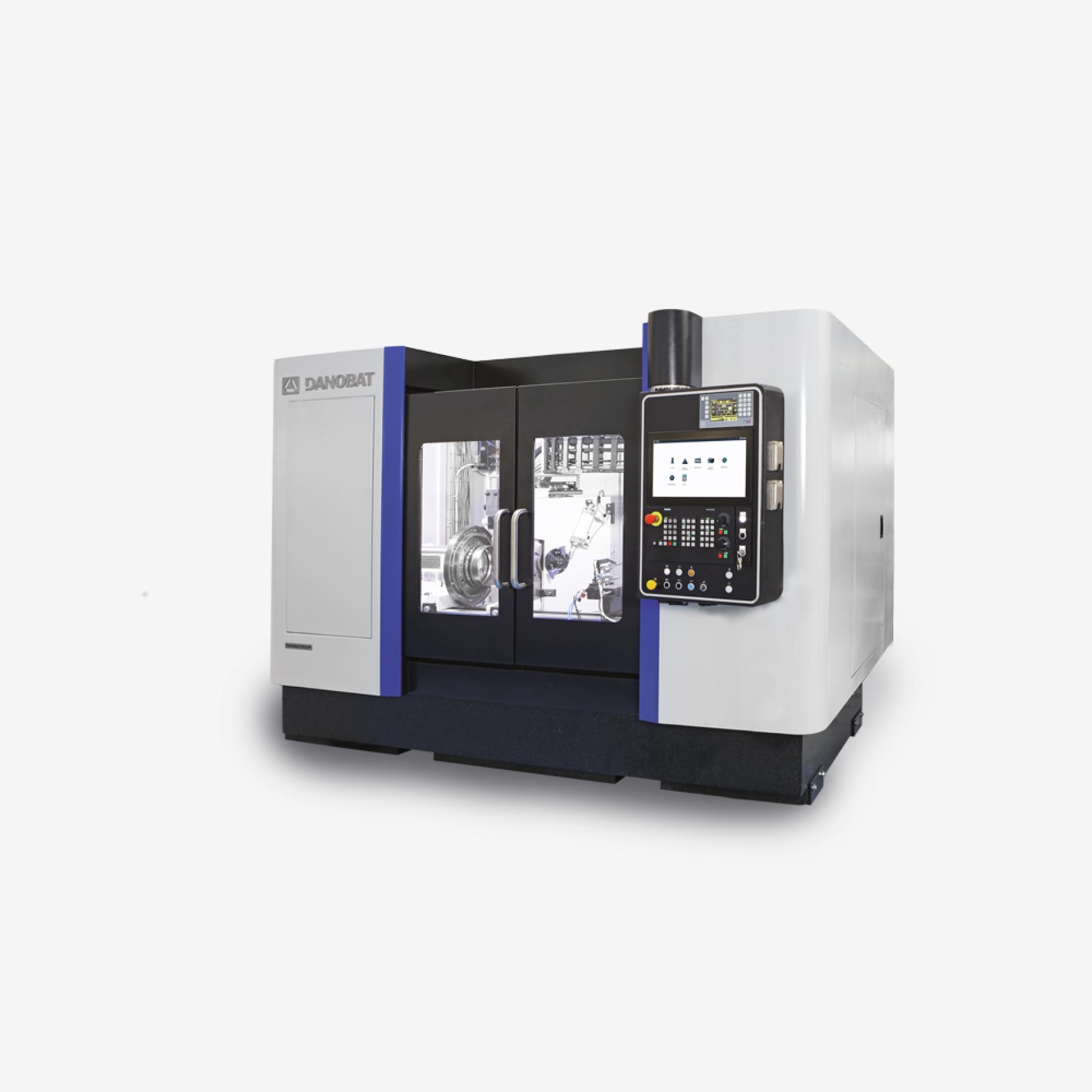

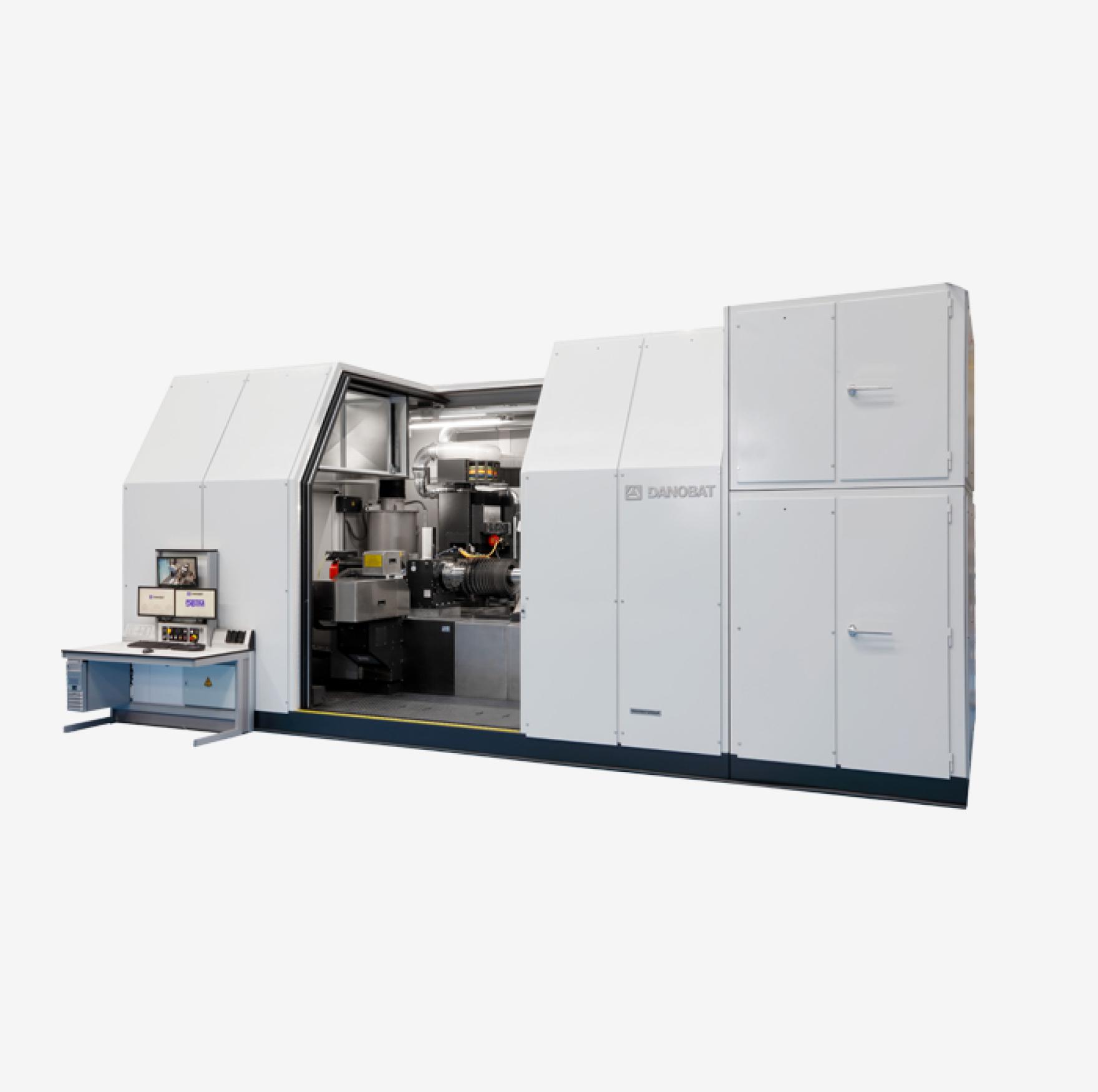

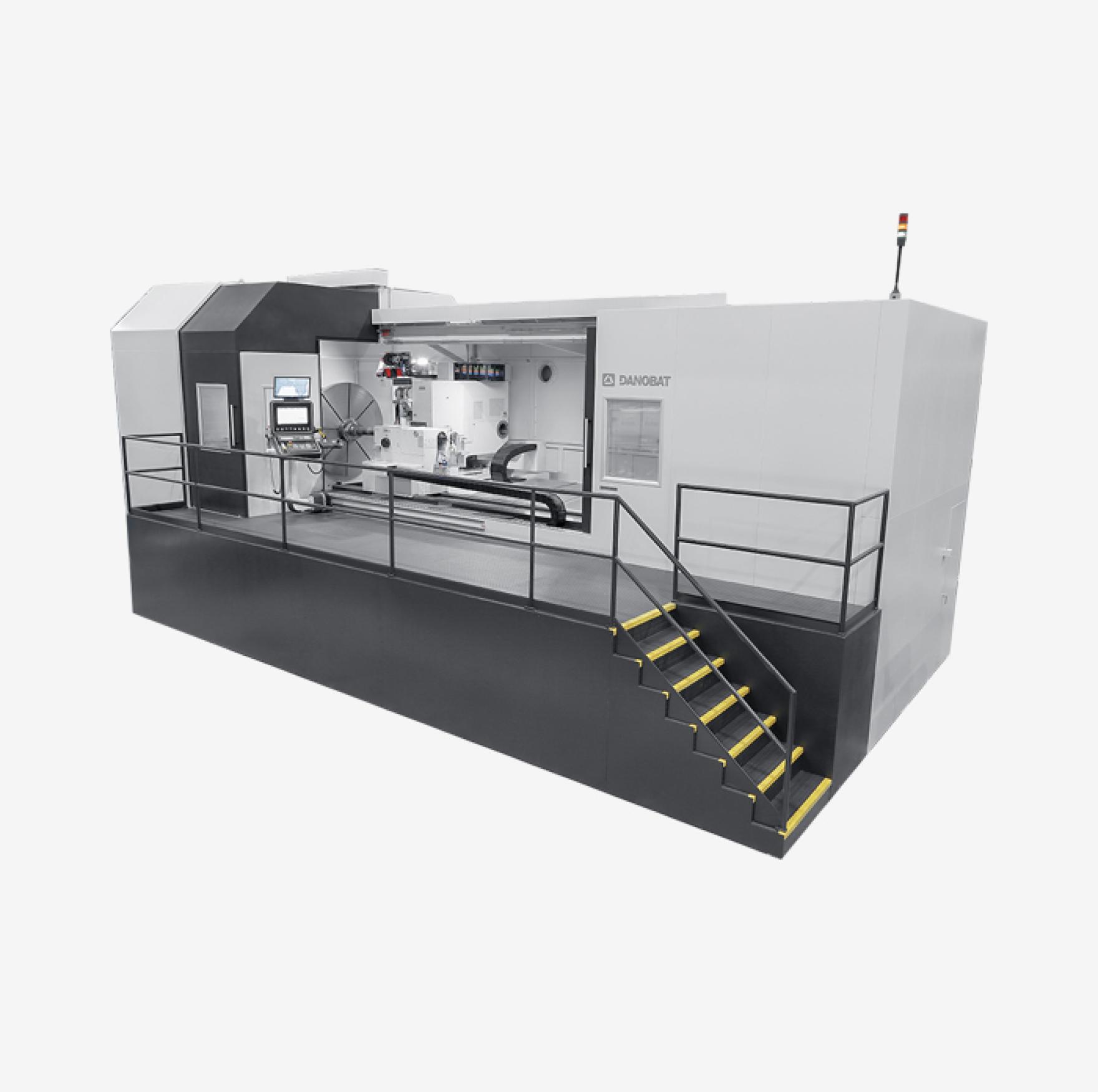

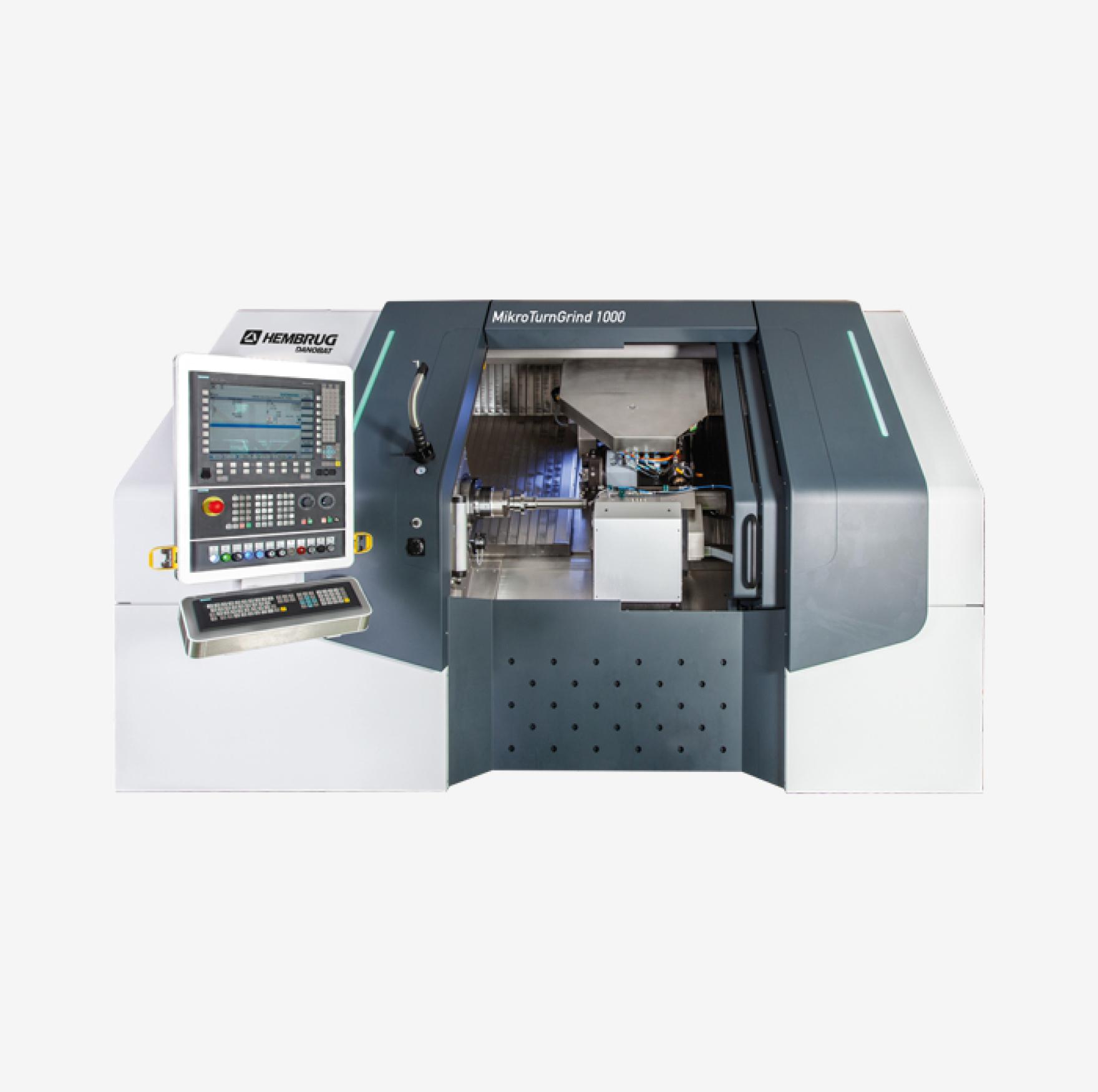

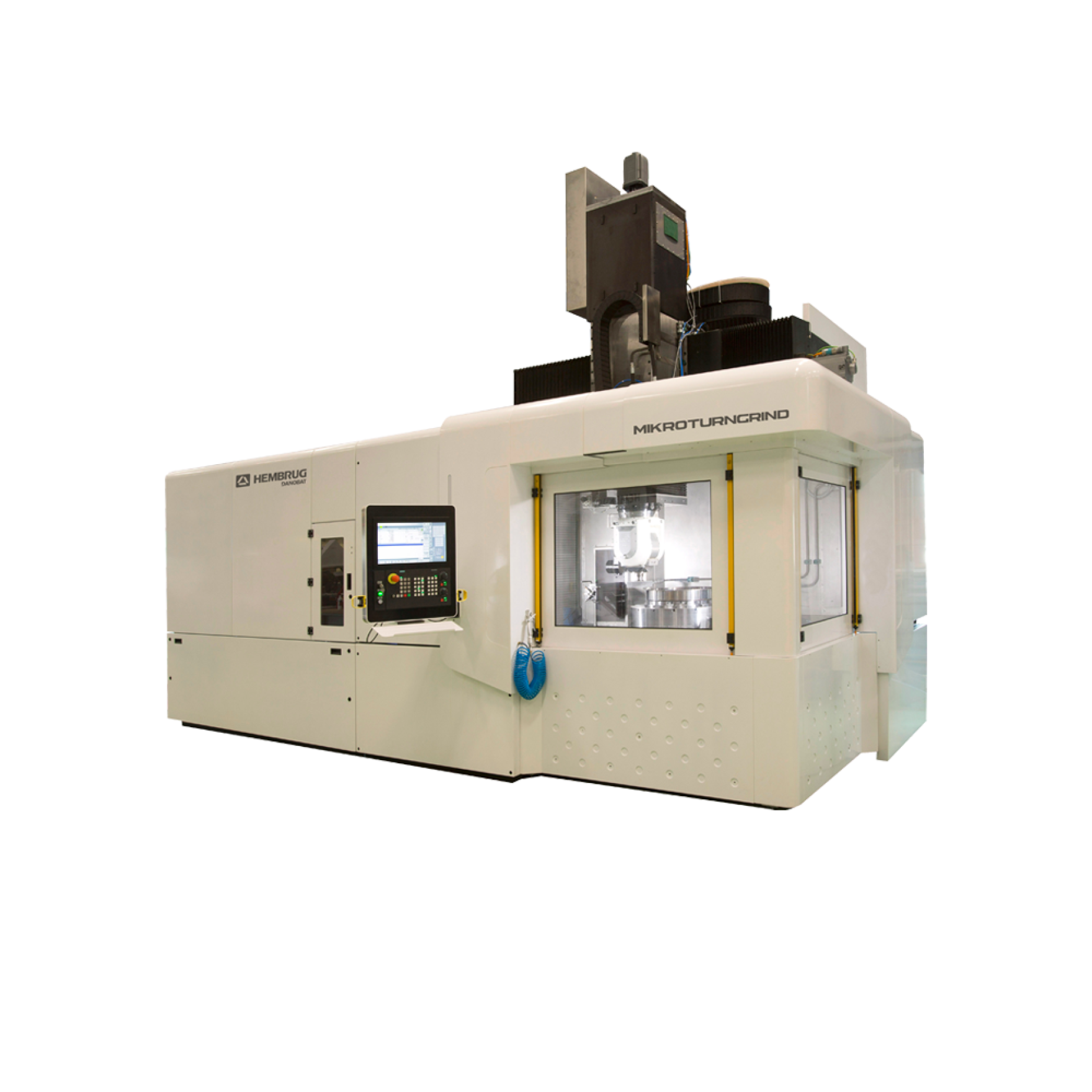

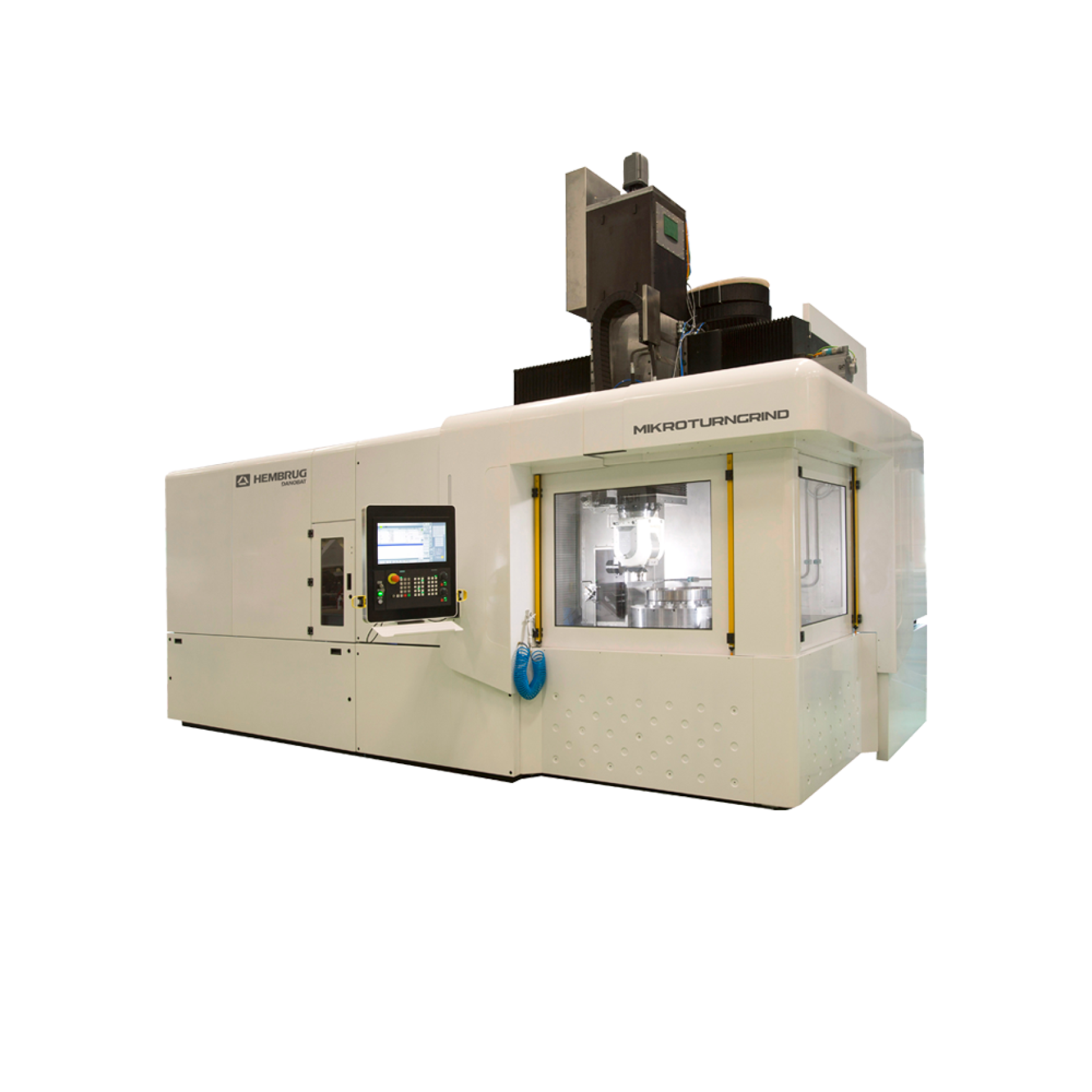

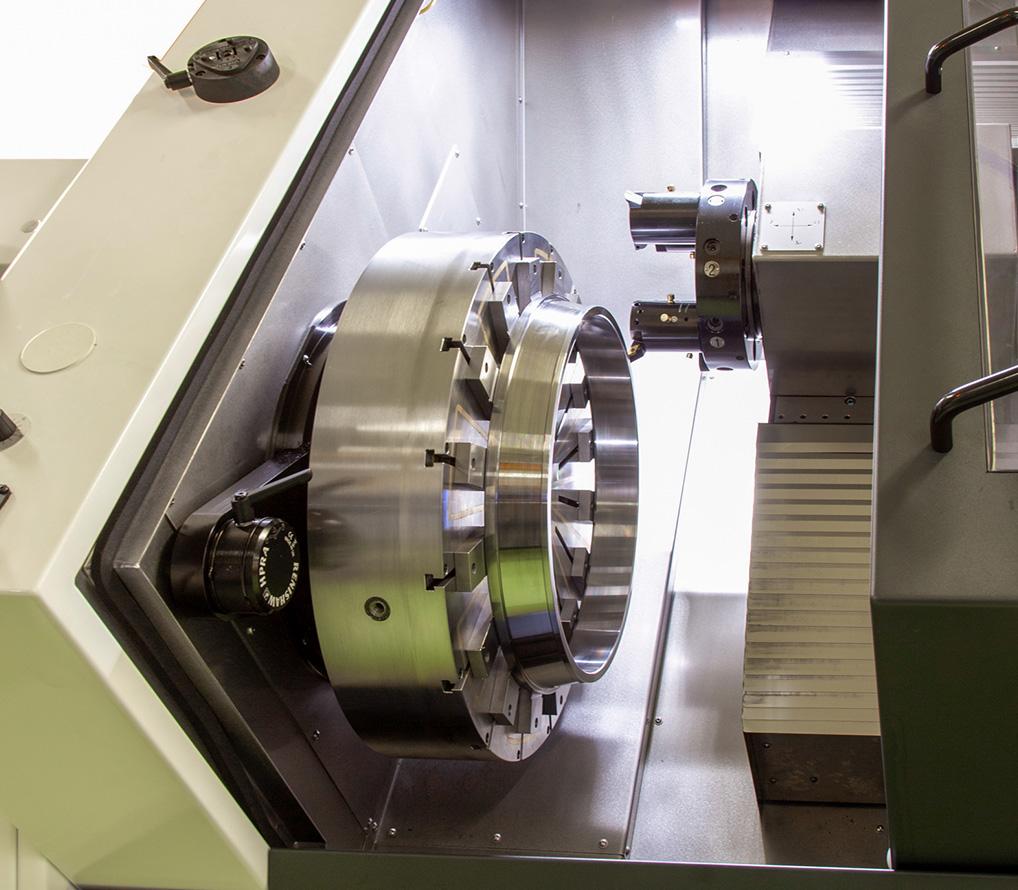

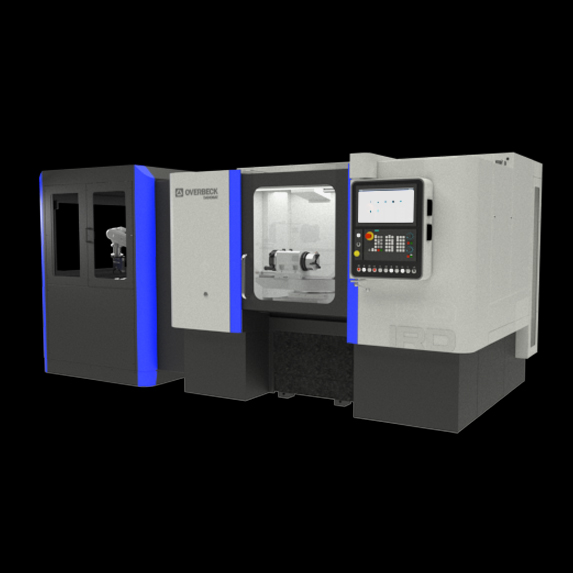

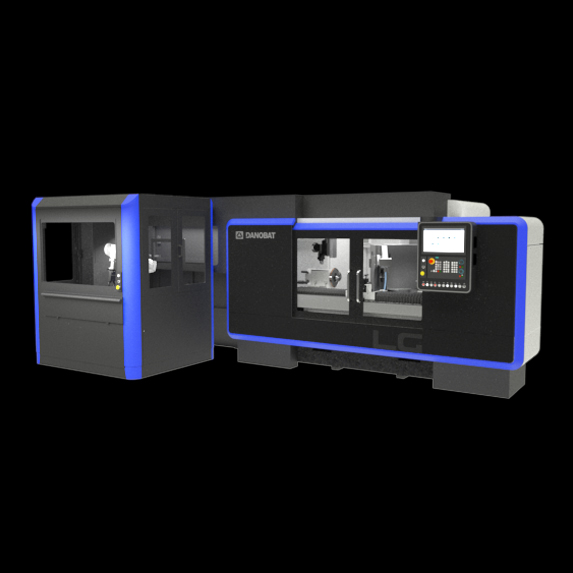

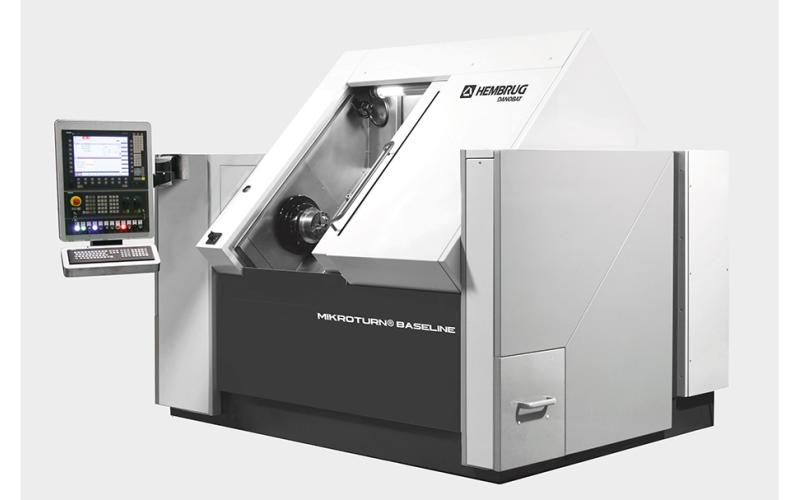

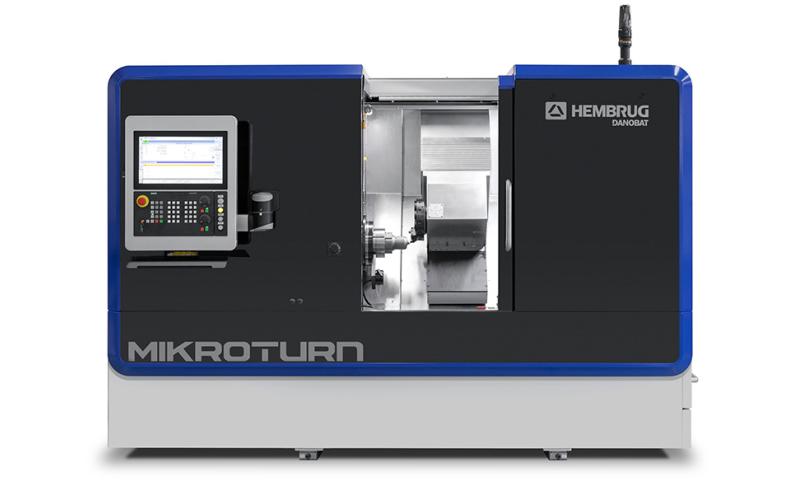

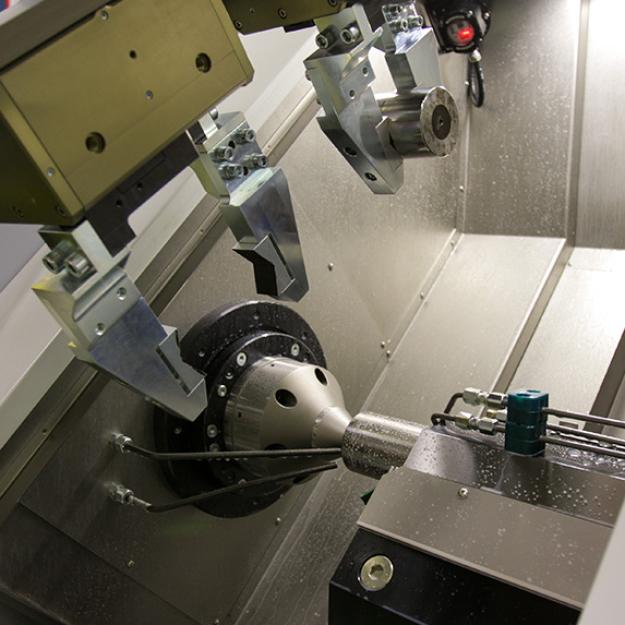

HIGH PRECISION HORIZONTAL HARD TURNING MACHINE

The Mikroturn is an ultra precise, fully hydrostatic, horizontal hard turning machine for hardened workpieces up to 70 HRC.

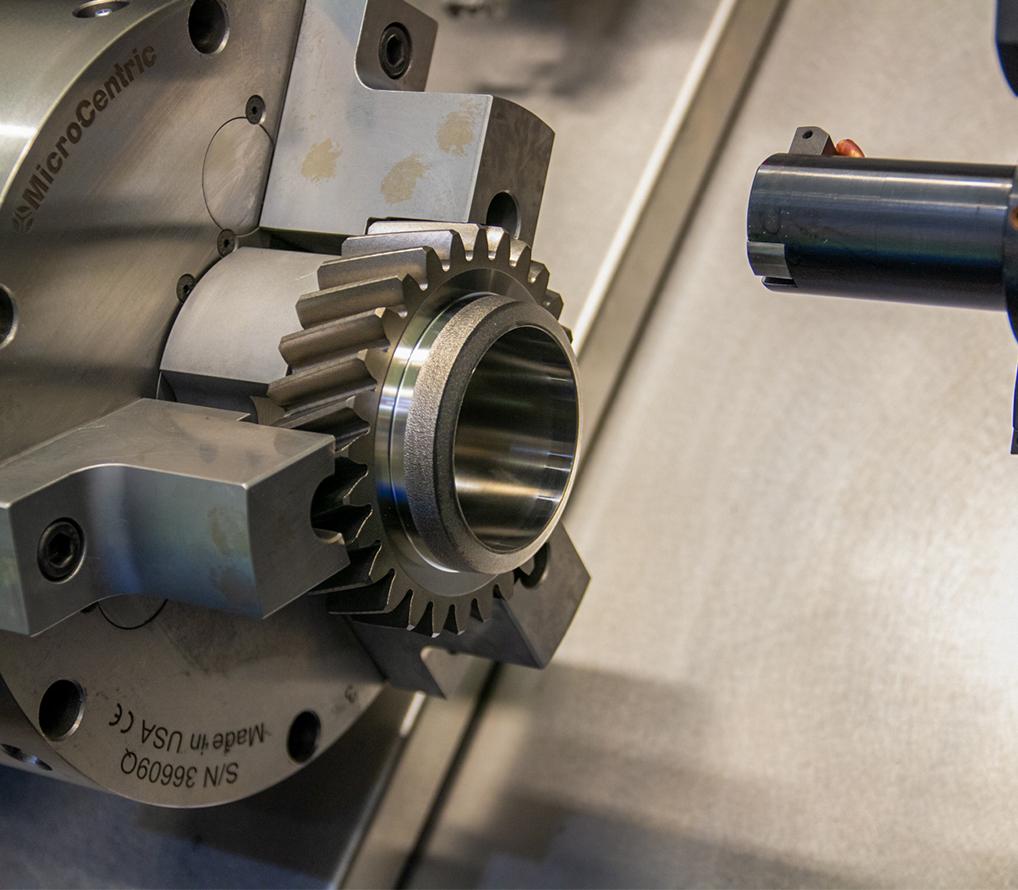

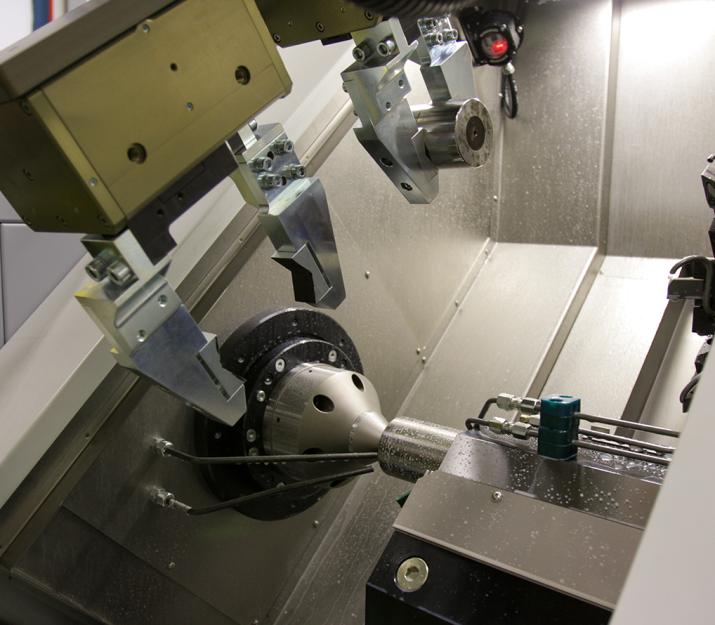

You can machine workpieces with complex contours, or perform combinations of ID and OD machining in a single clamping, avoiding re-clamping errors.

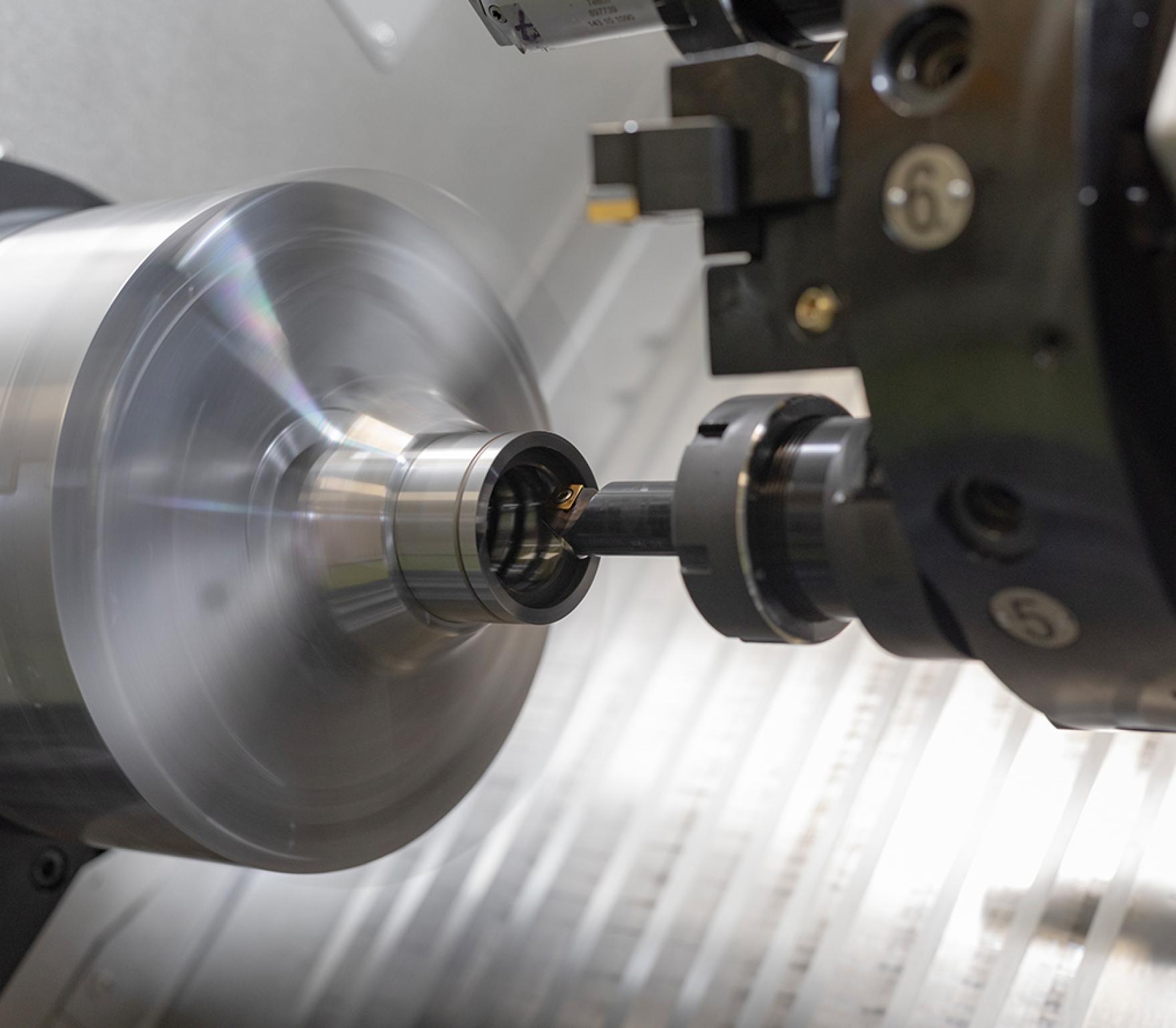

Wear-free hydrostatic main spindle

High precision hydrostatic main spindle with a guaranteed runout error ≤ 0.000004” (0,1 µm).

High dynamic stiffness, high surface accuracy, and excellent tool life.

Granite base and main spindle housing

All components critical for precision are mounted on a natural granite base, which is inherently temperature stable and vibration damping. Plus vibration absorbing mounts isolate the granite base from the machine’s metal frame.

Corrosion-free and free of any stresses.

Wear-free hydrostatic guideways

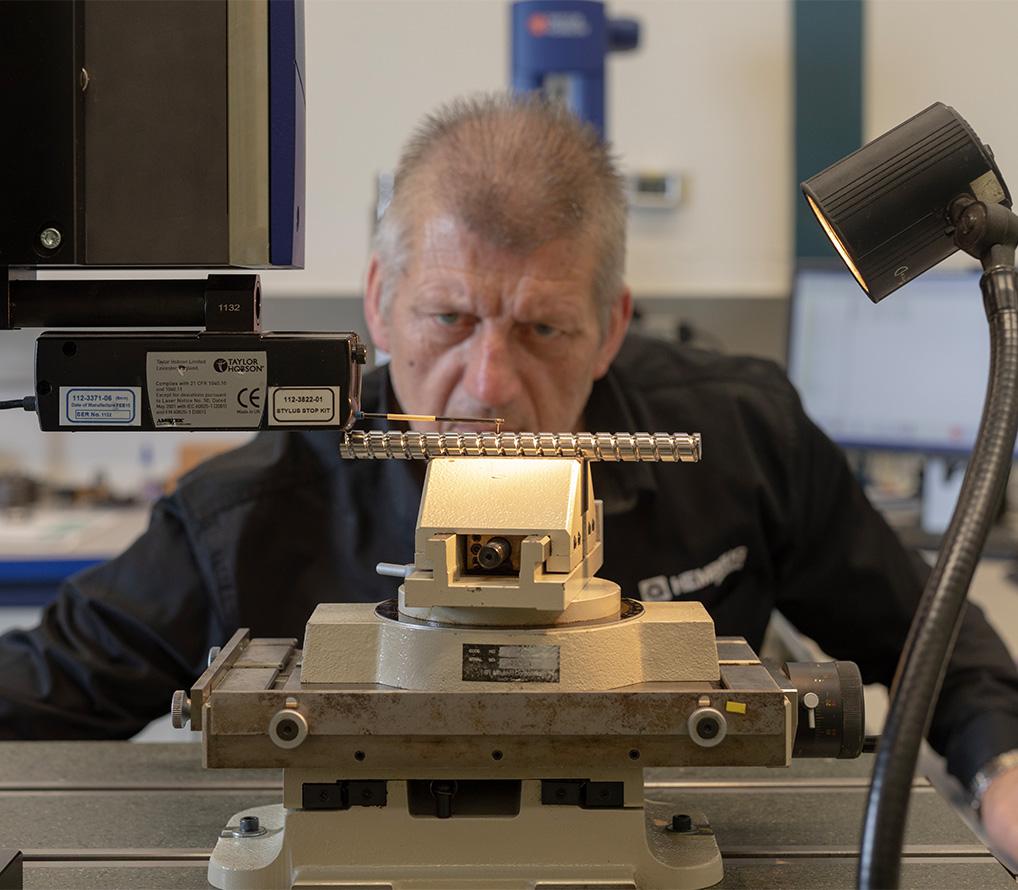

High precision hydrostatic guideways having 0.00004” (1 µm) positioning and 0.000008” (0,2 µm) repeatability, controlled by linear scales.

Thermal stability

Heat sources and vibrating elements are placed outside the machining area, ensuring excellent thermal stability during series production.

Siemens or Fanuc control

Siemens Sinumerik One or Fanuc 32i CNC control, with 0.0000004” (0,01 µm) resolution.

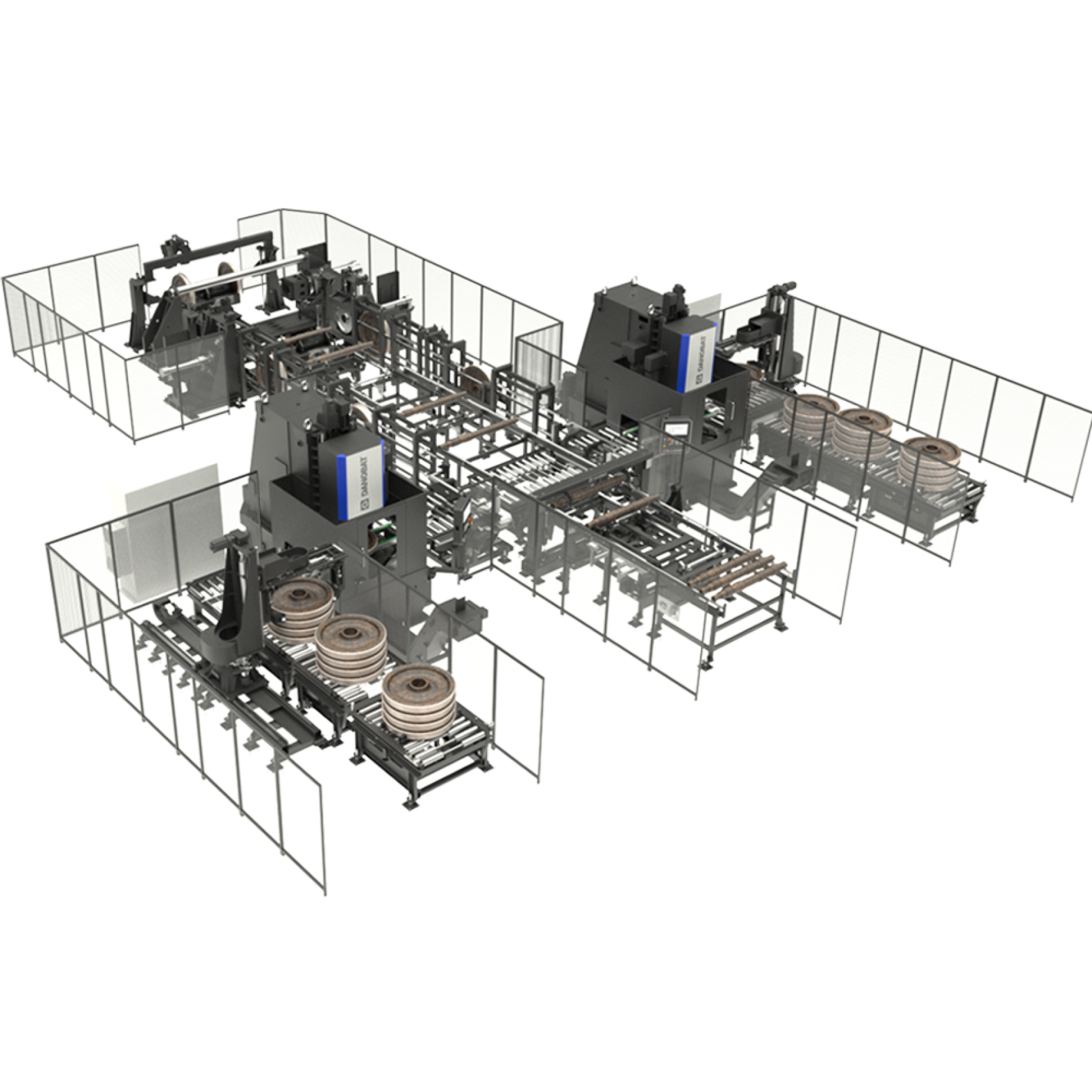

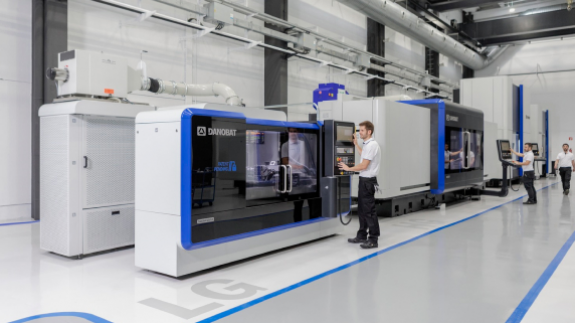

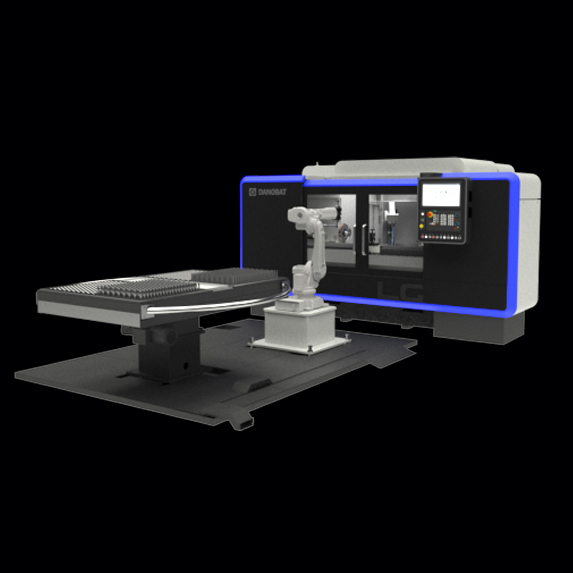

We can offer you a machine including (un)loading systems, feeding or storage systems, and auxiliary stations.

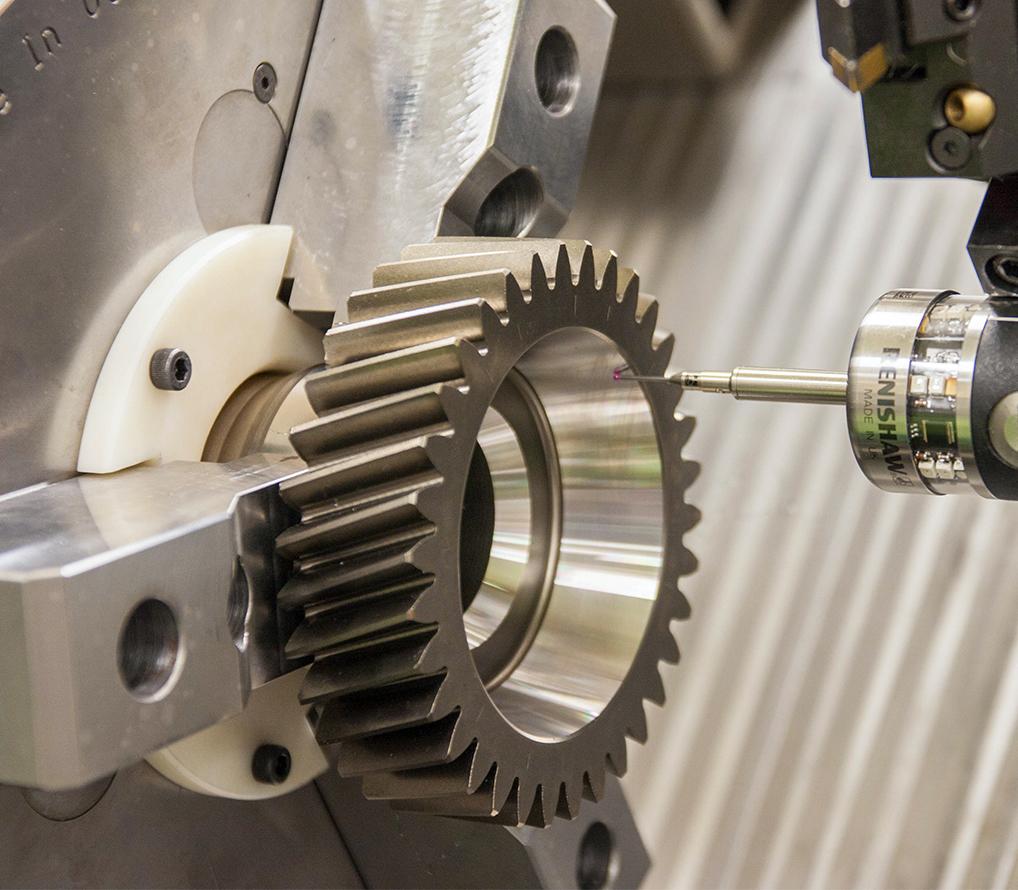

Gears

Dressing tools

Steering nut

Punch

Die

Neck ring

Inner & outer ring

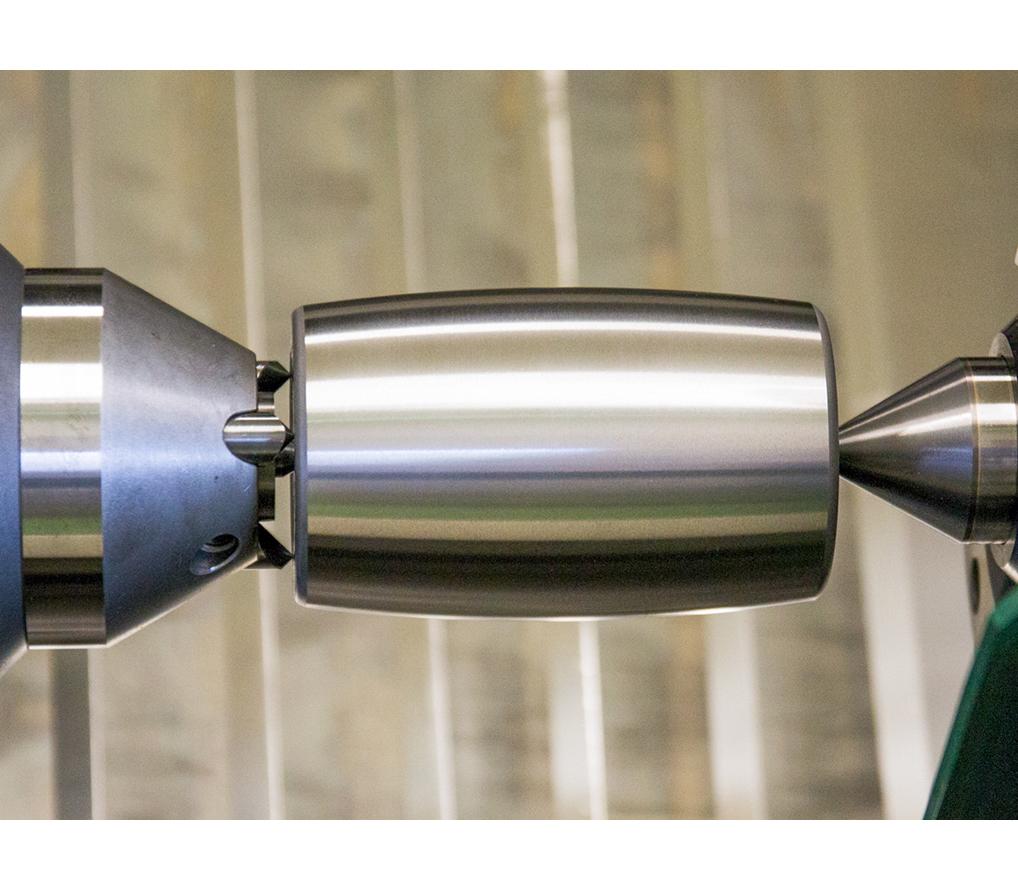

Roller

Gear pump shaft

Piston for radial & axial motors

Spool valve

EV motor shaft

Ball screw nut

Machine tool spindle shaft

Hip joint

Toolholder

- Customized maintenance plans based on your production needs: ballbar test, verification of geometry and much more

- Retrofitting: We overhaul the complete machine or specific modules, such as the workhead and guiding systems

- Engineering and process development: Select the proper clamping and tooling solution for your new part