Email us

UARC

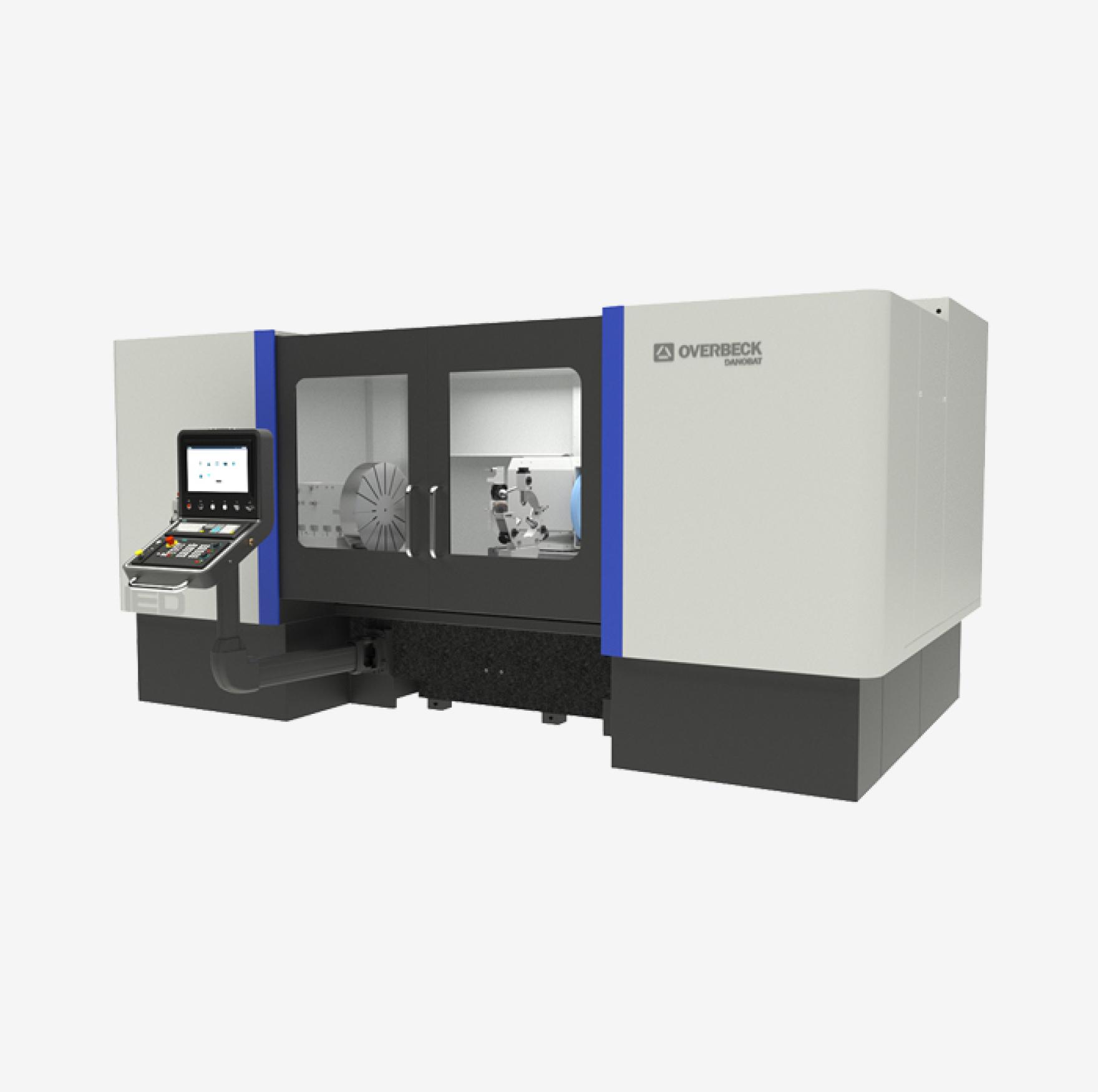

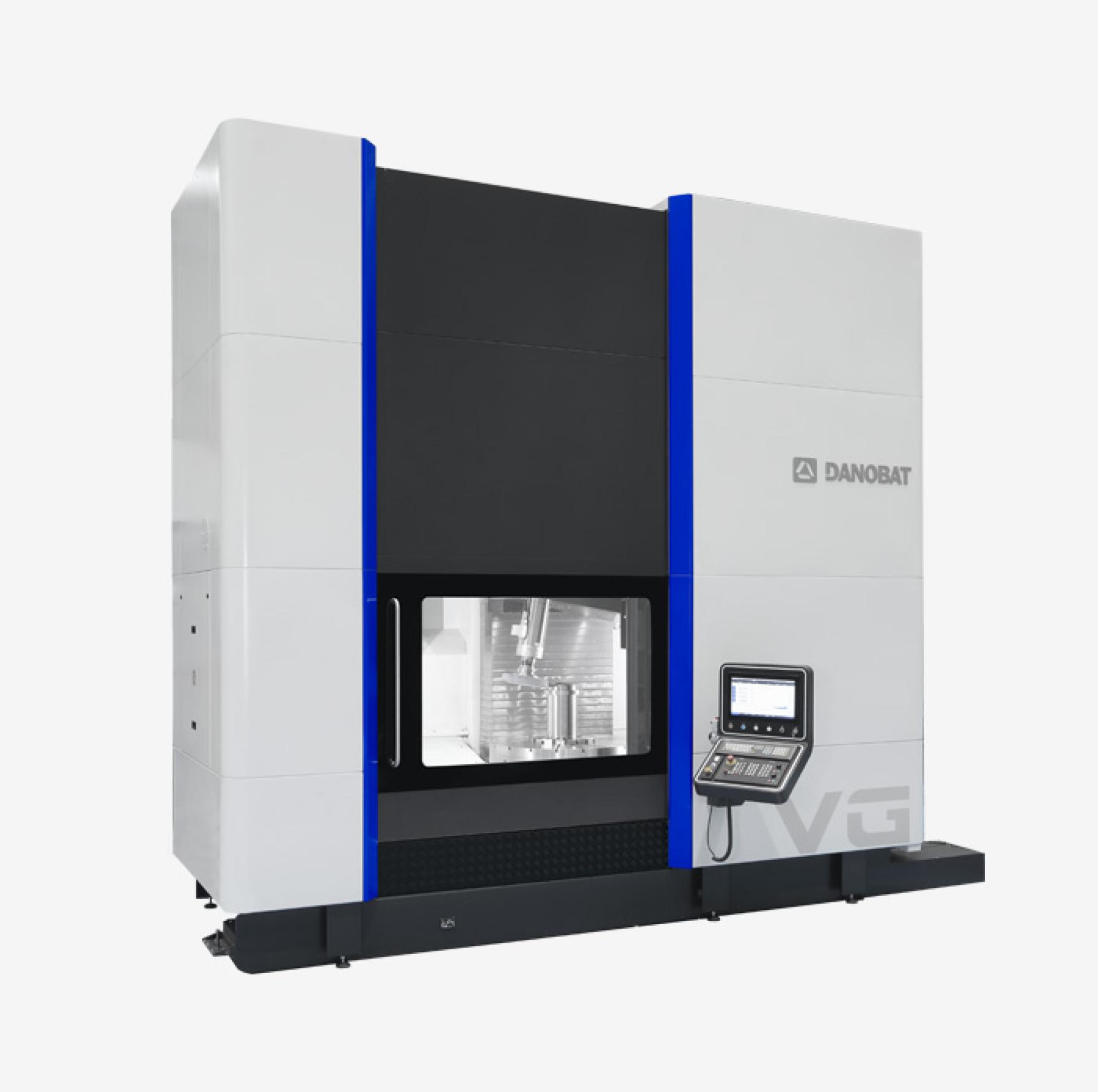

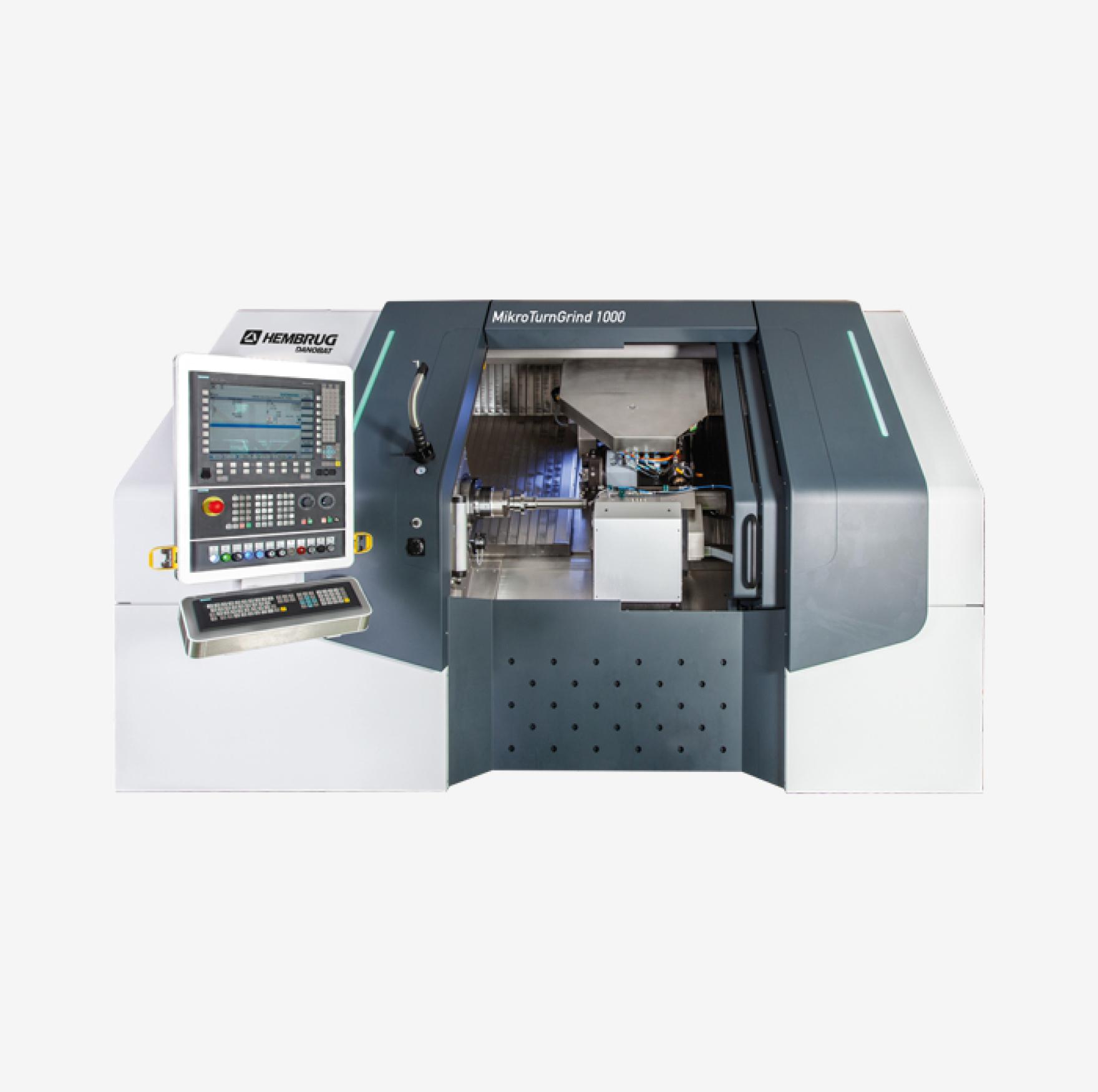

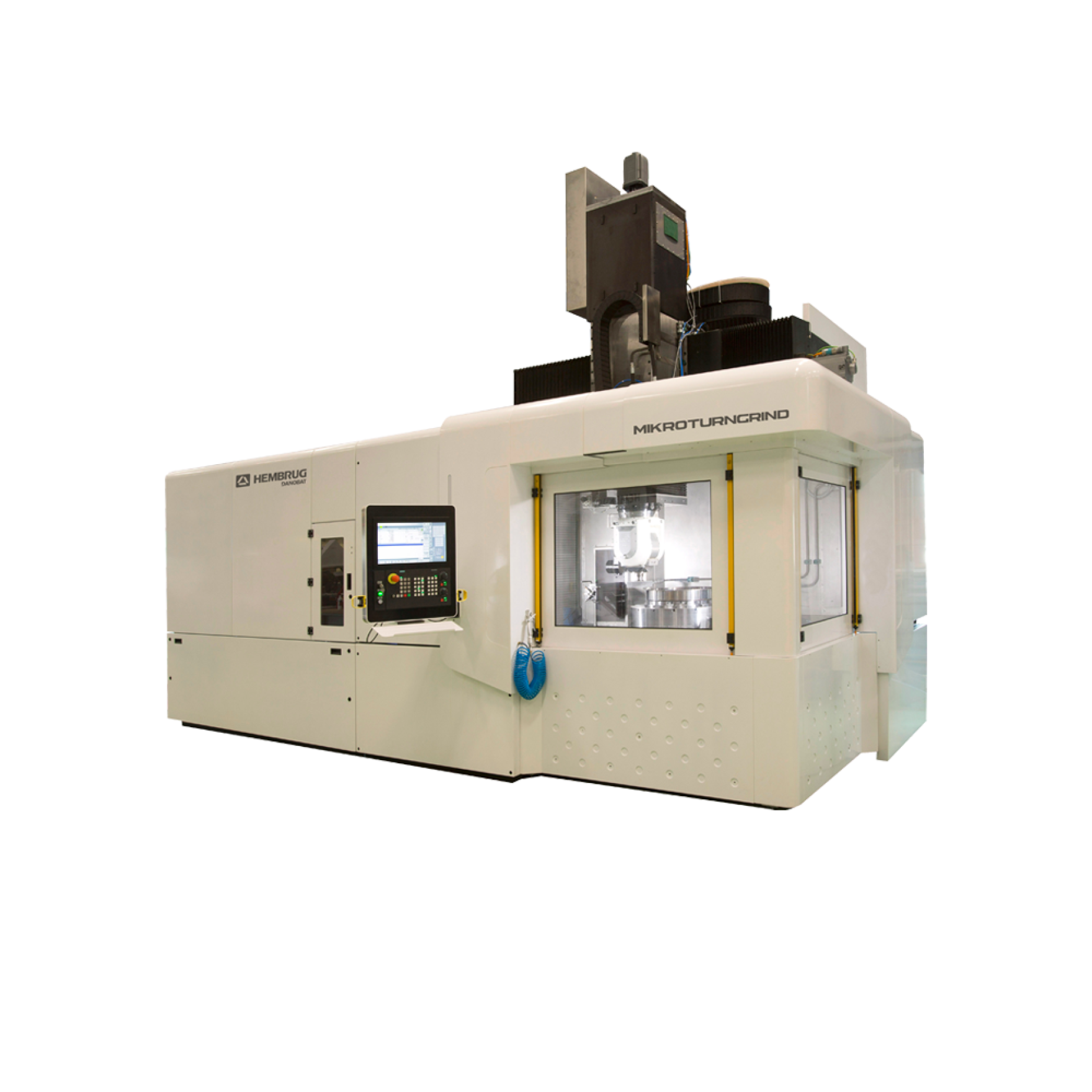

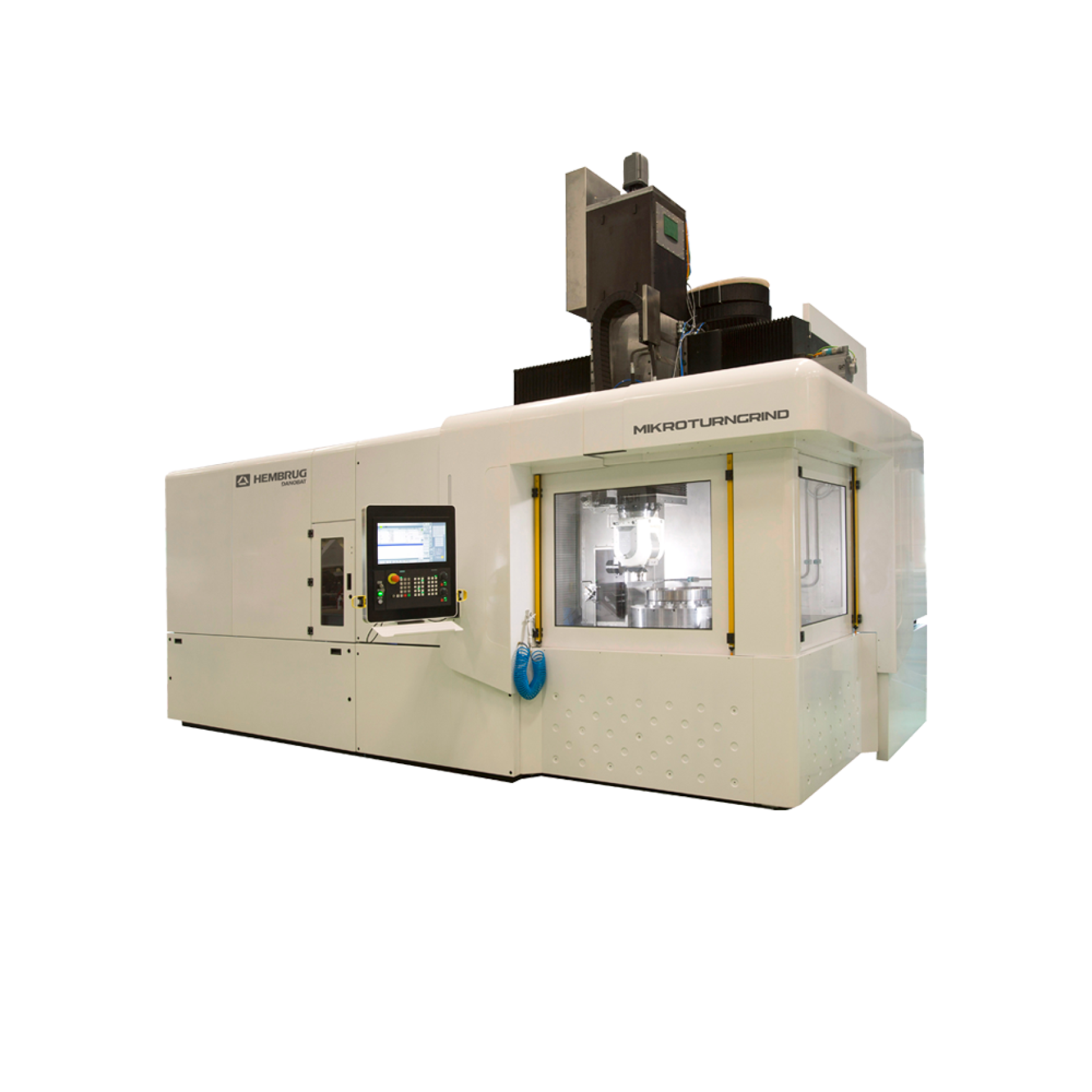

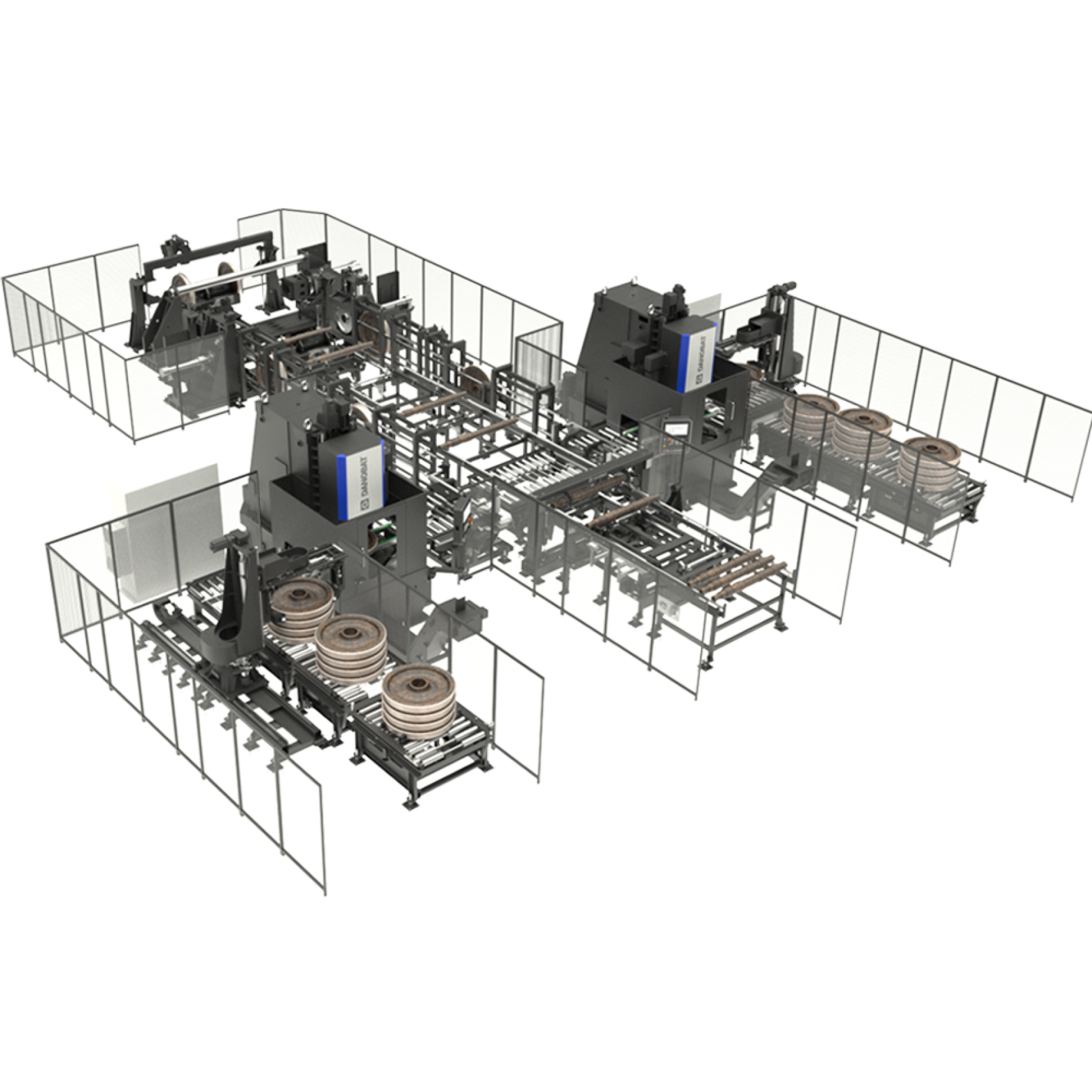

AUTOMATED USED AXLE REPAIR & RECONDITIONING CELL

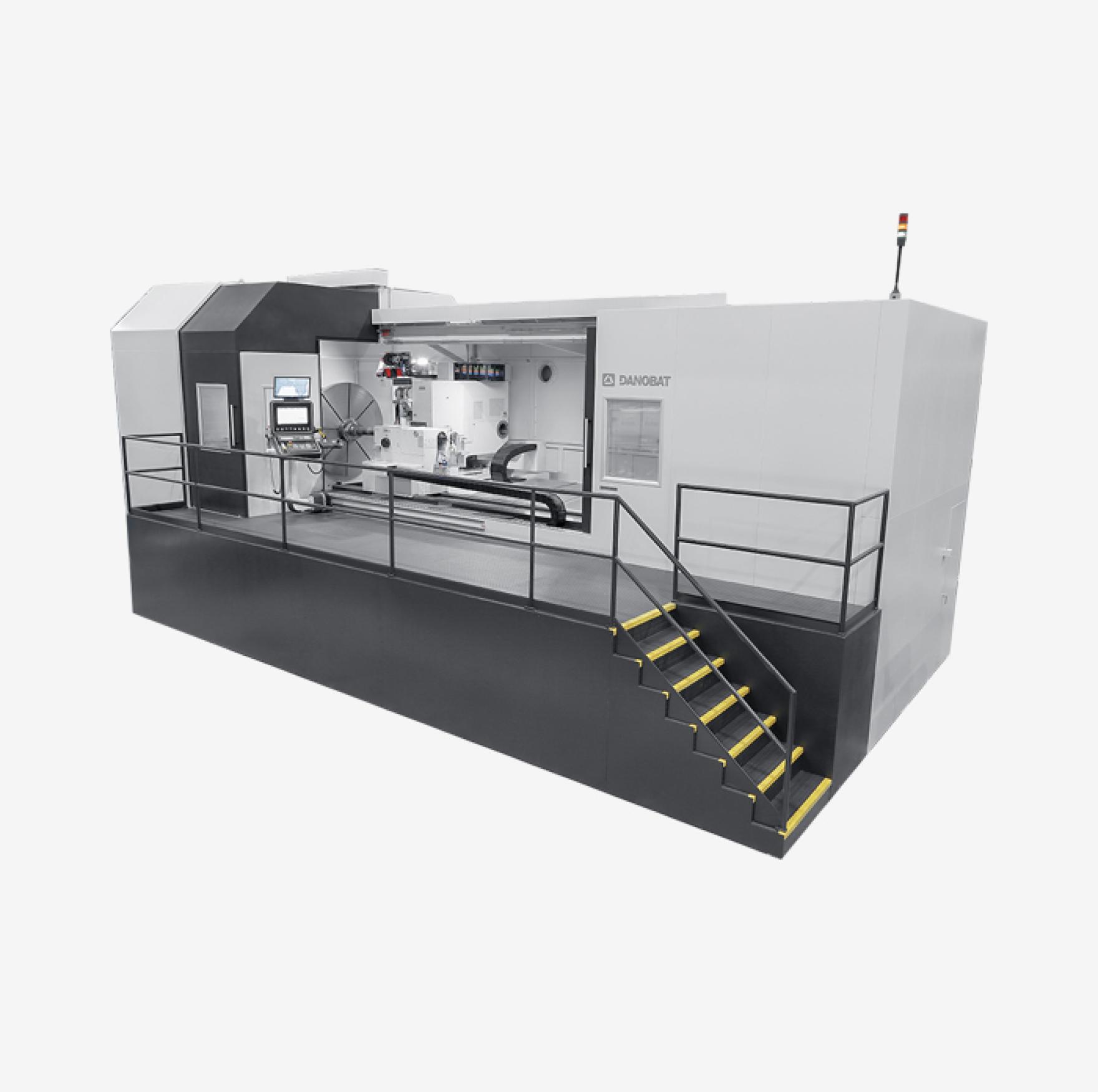

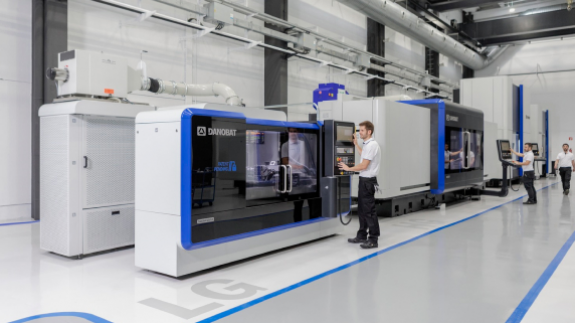

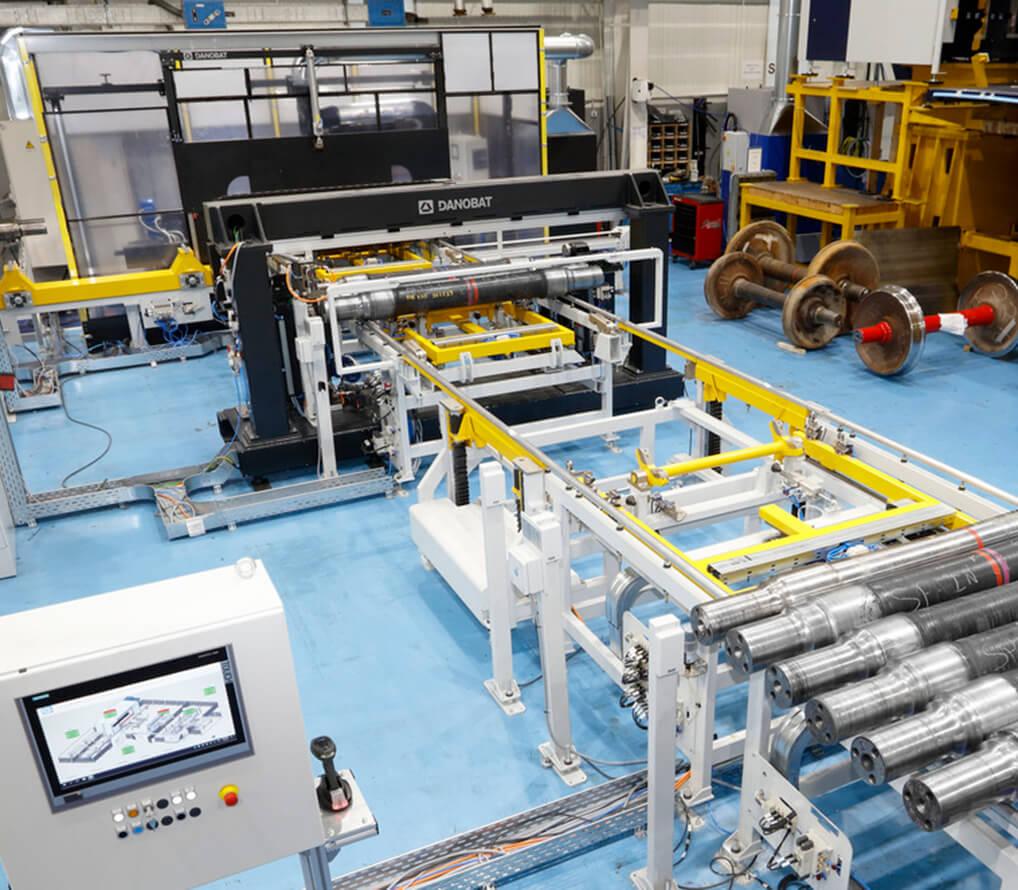

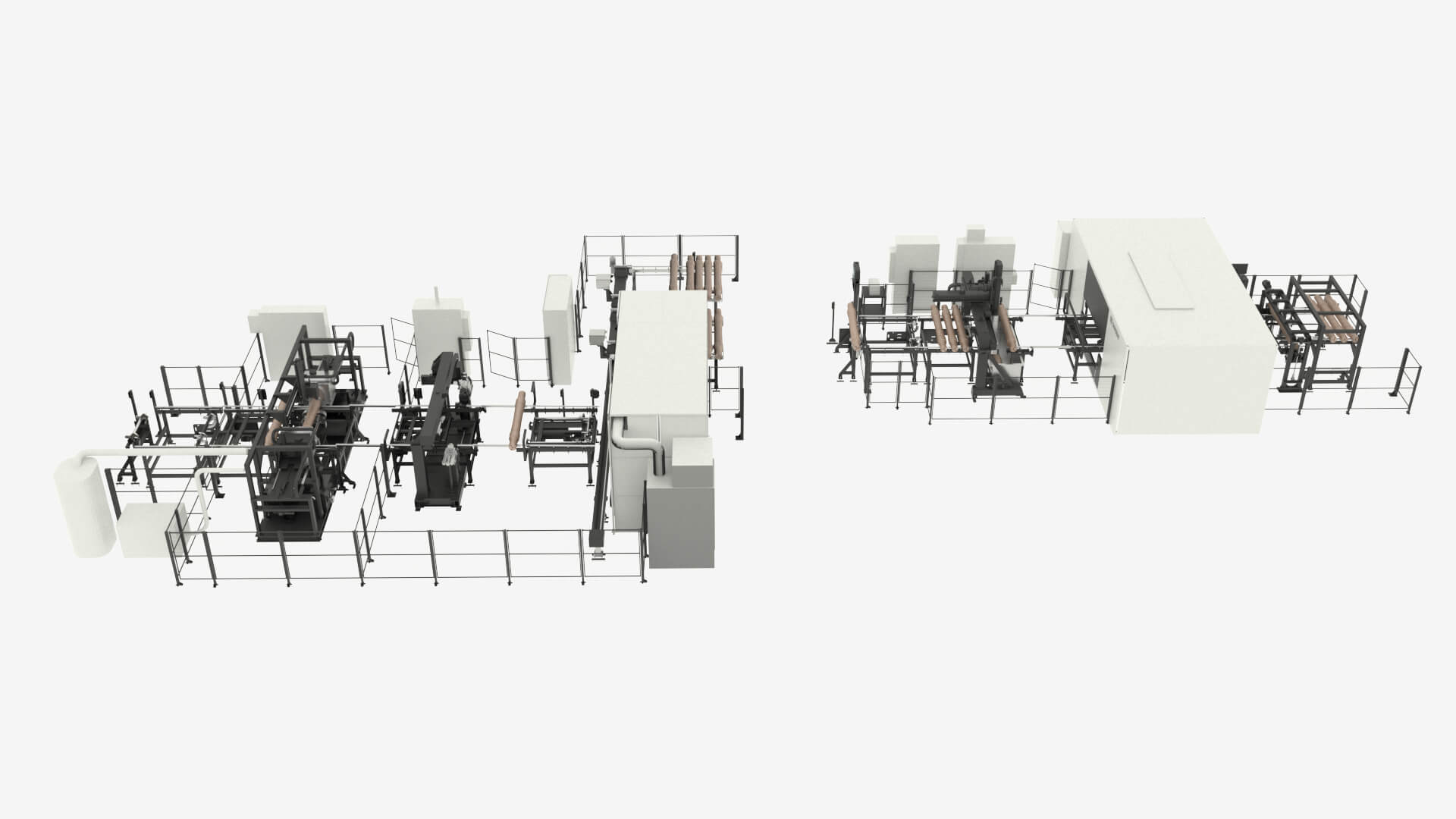

This cell reconditions used railway axles very efficiently, thanks to a key feature: almost all operations are automated.

The cell includes cleaning, measuring and repair units. It also performs post-process ultrasonic and magnetic particle inspections.

Technology

When it comes to reconditioning an axle, every detail matters

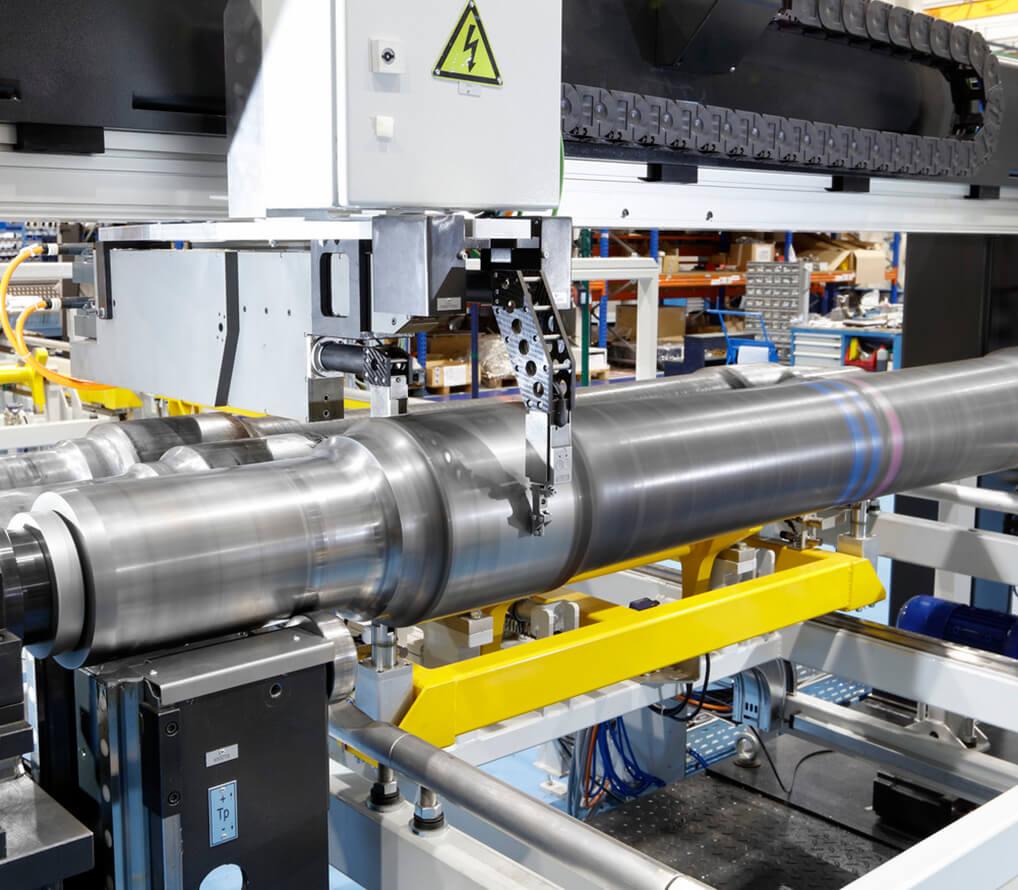

Automatic axle cleaning

- Dry brush cleaning of the middle of the axle

- Brushing with water and detergent at the end

- Optimal surfaces for subsequent measurements

Automatic axle measurement

- Developed in-house

- Precise and repeatable measurements—with thermal compensation

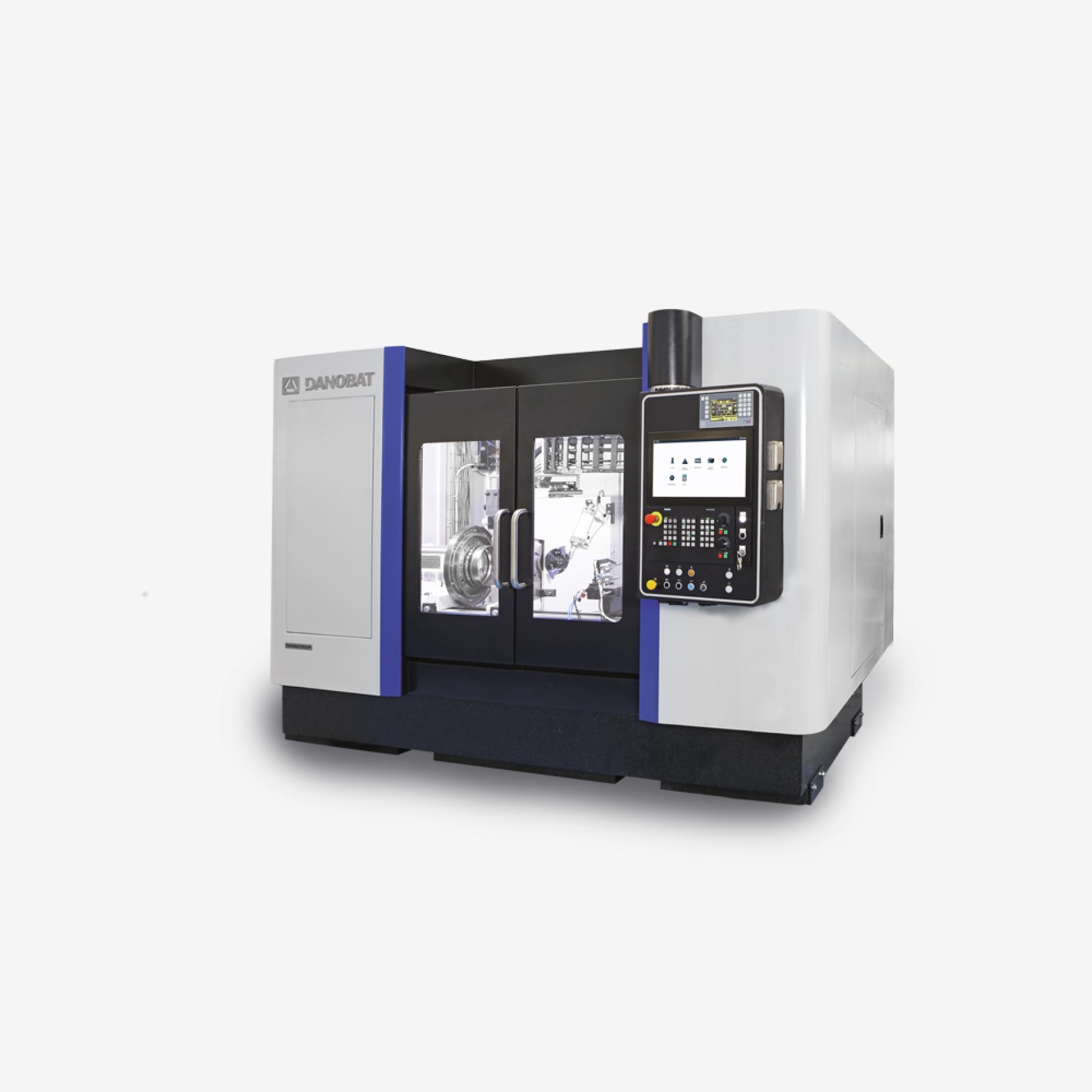

Axle refurbishment cabin

Cab specifically designed for axle repair tasks, maximising operator comfort and safety.

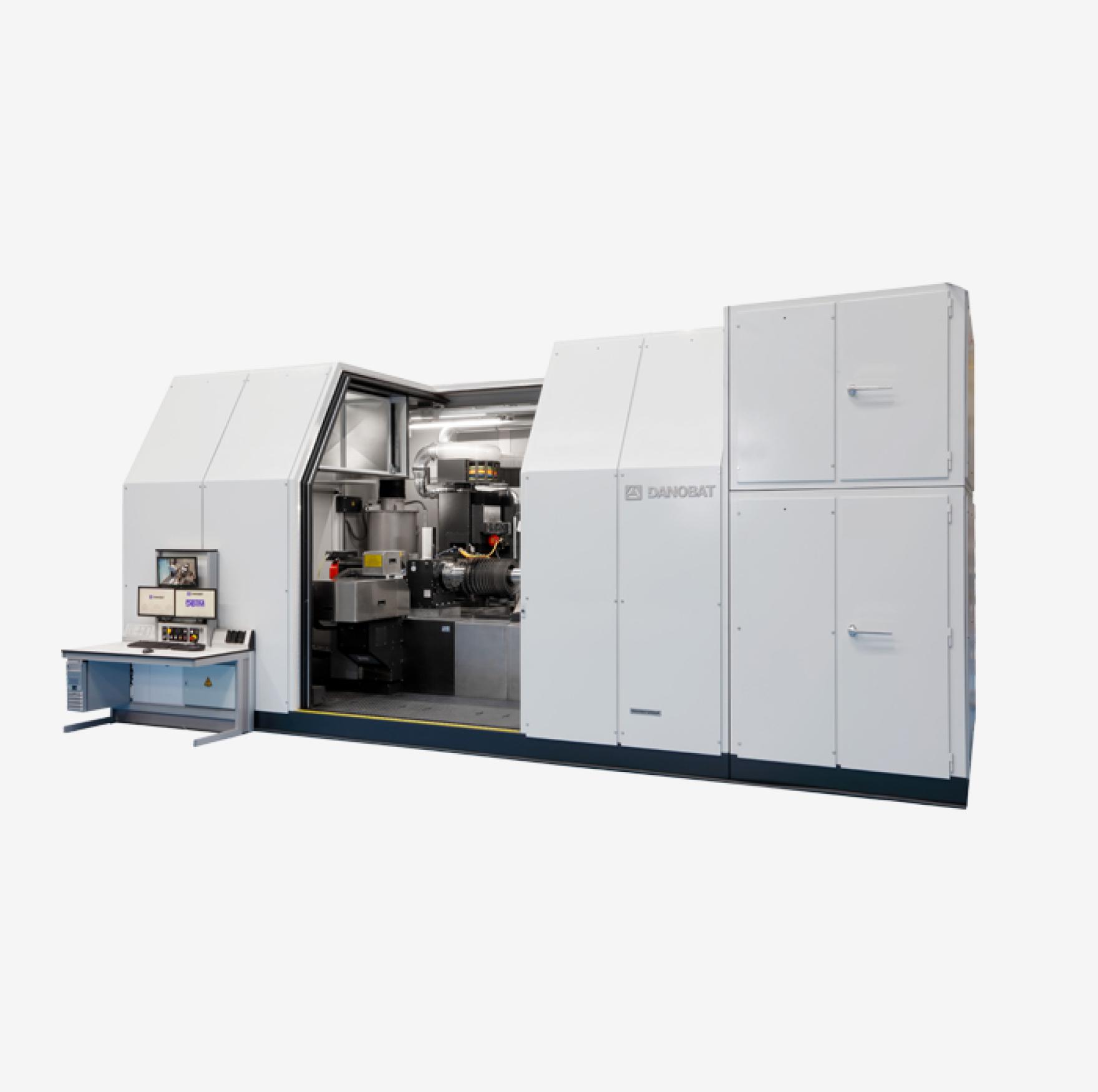

Non-destructive inspection (UT)

Automatic ultrasonic internal flaw detection.

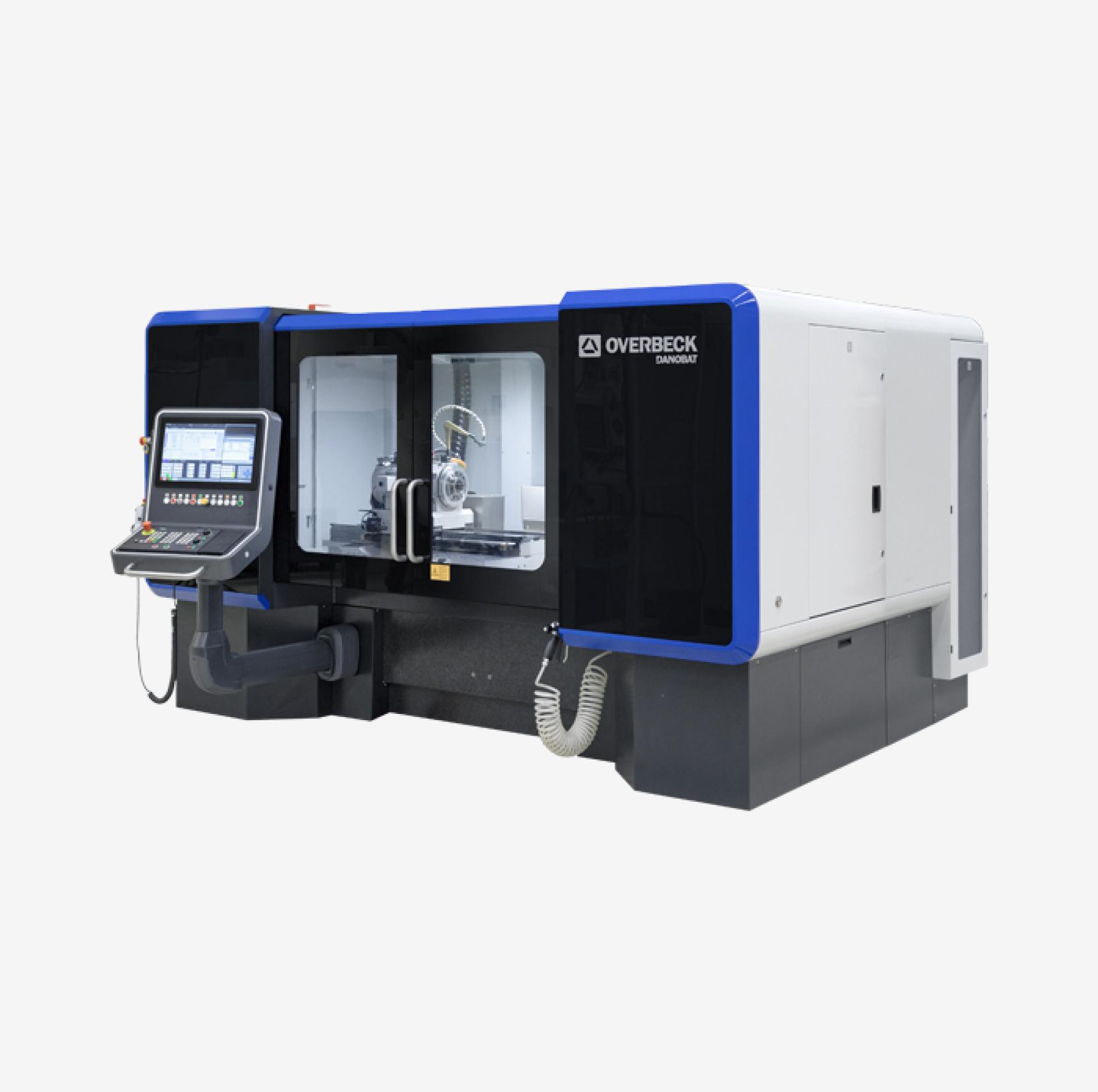

Surface check by magnetic particle inspection (MPI)

Automatic detection of surface defects by magnetic particle inspection.

Workpieces

Railway axle

Service

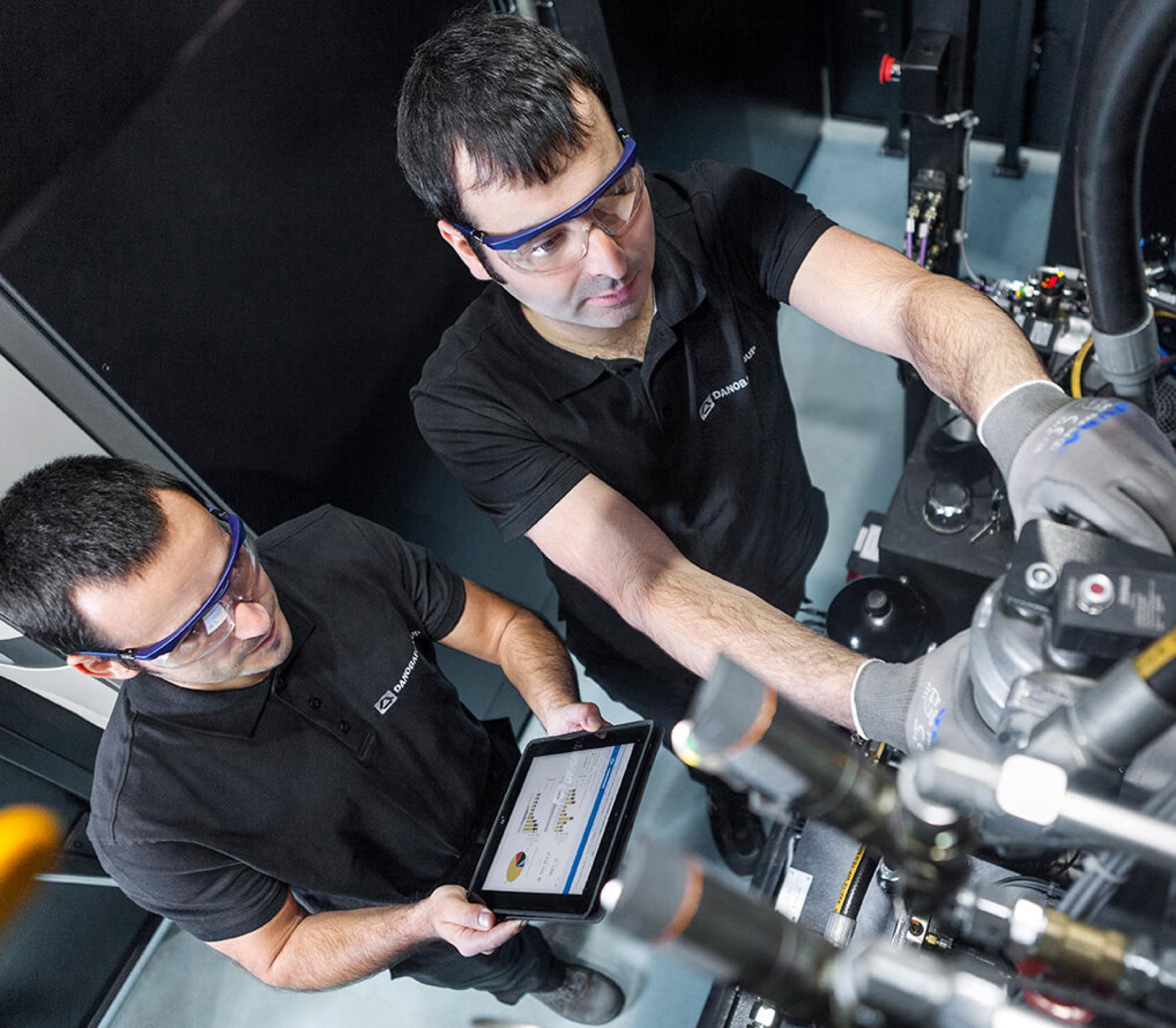

We offer services to keep your UARC in the best condition

- Yearly preventive maintenance, calibration, and customised plans managed by a seasoned team

- We are prepared to assist you remotely. We respond and manage your request worldwide

Digital

Are you interested in enhancing machine maintenance and machining processes?

Off