Email us

We are experts in the design and manufacture of advanced, high value-added, and engineered-to-order manufacturing solutions.

Qualified specialists, in-house technology, backing for innovation, and a corporate culture that places you at the heart of our organization.

The Danobat Way.

Grinding, turning, precision hard turning and hybrid machines

-

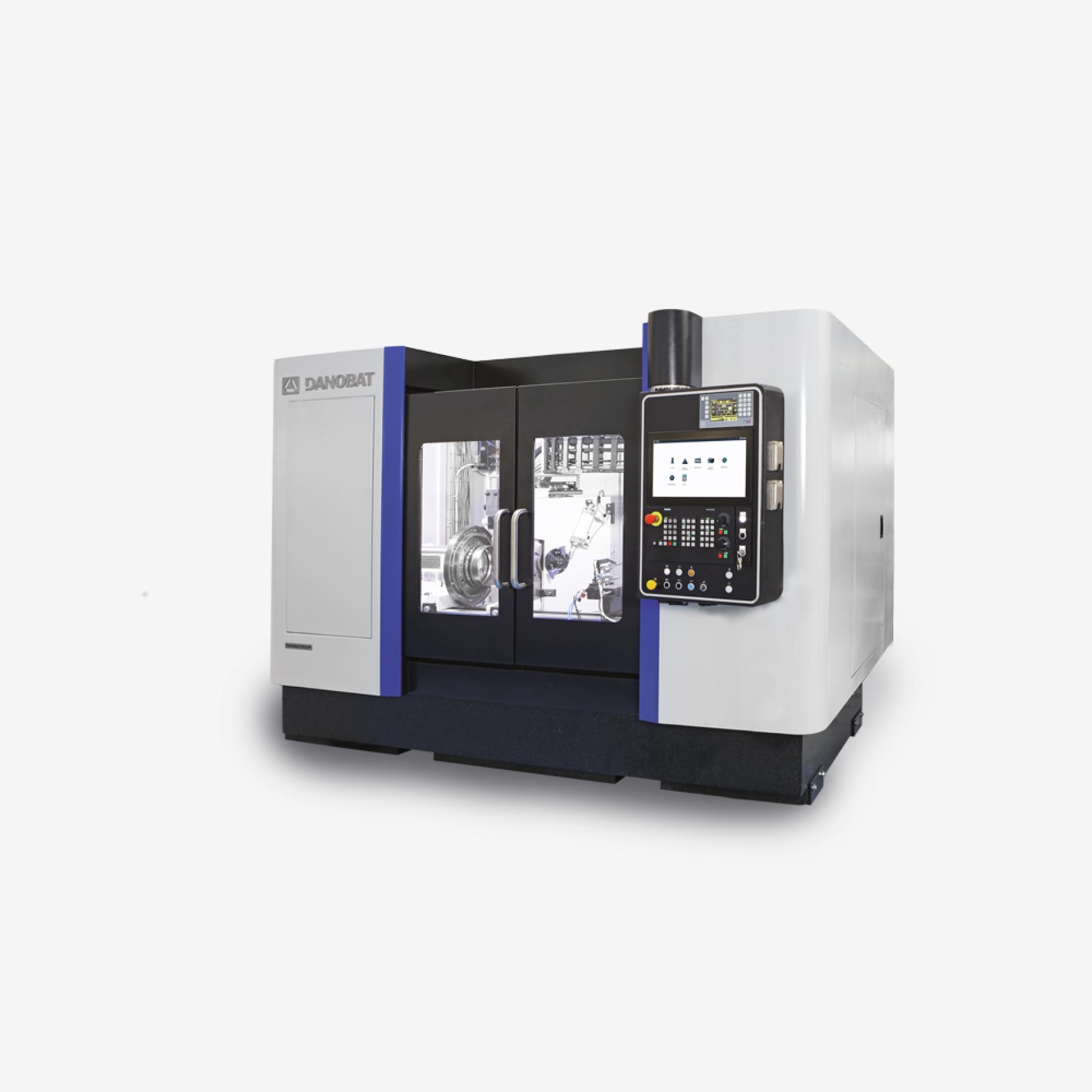

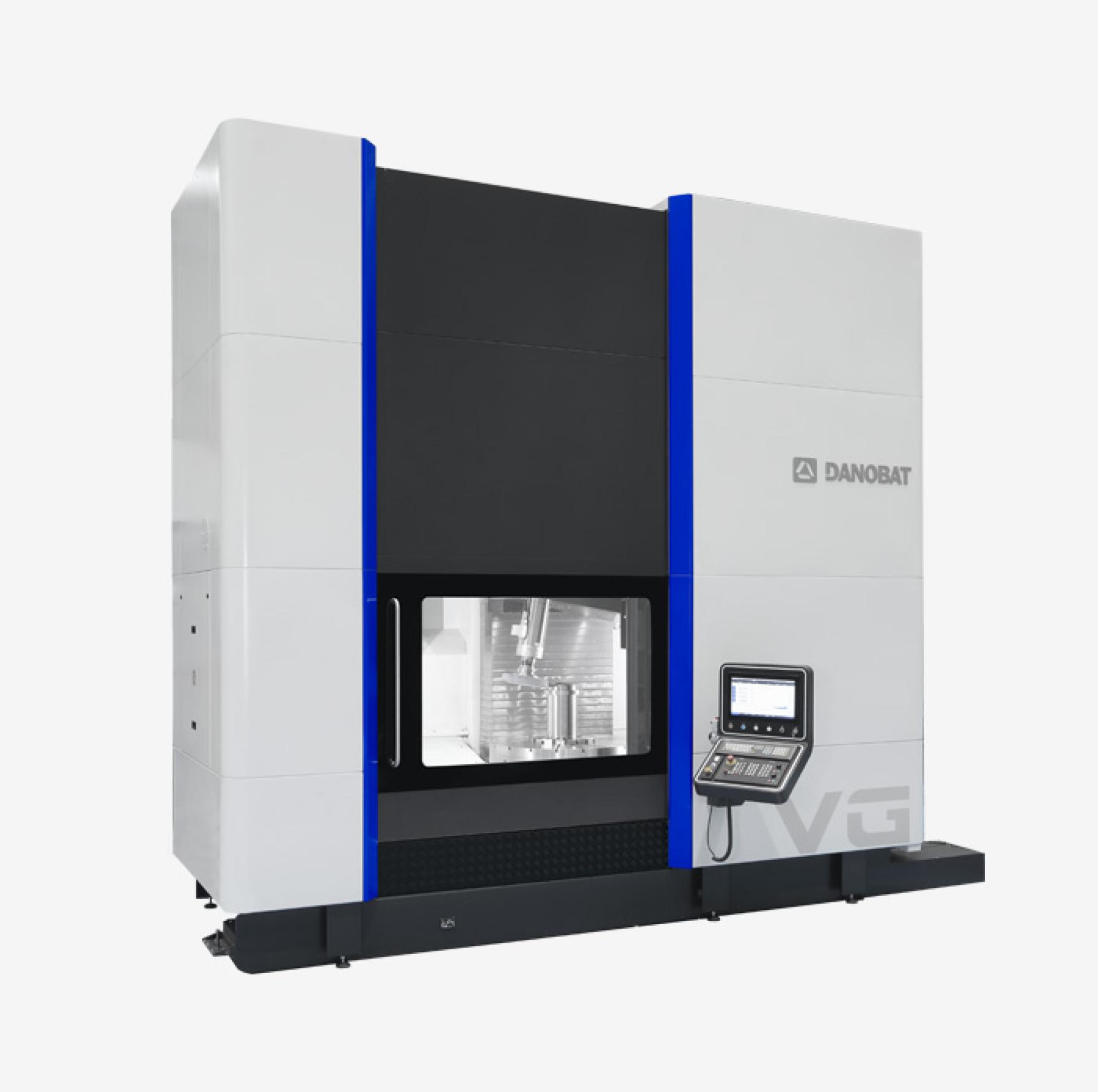

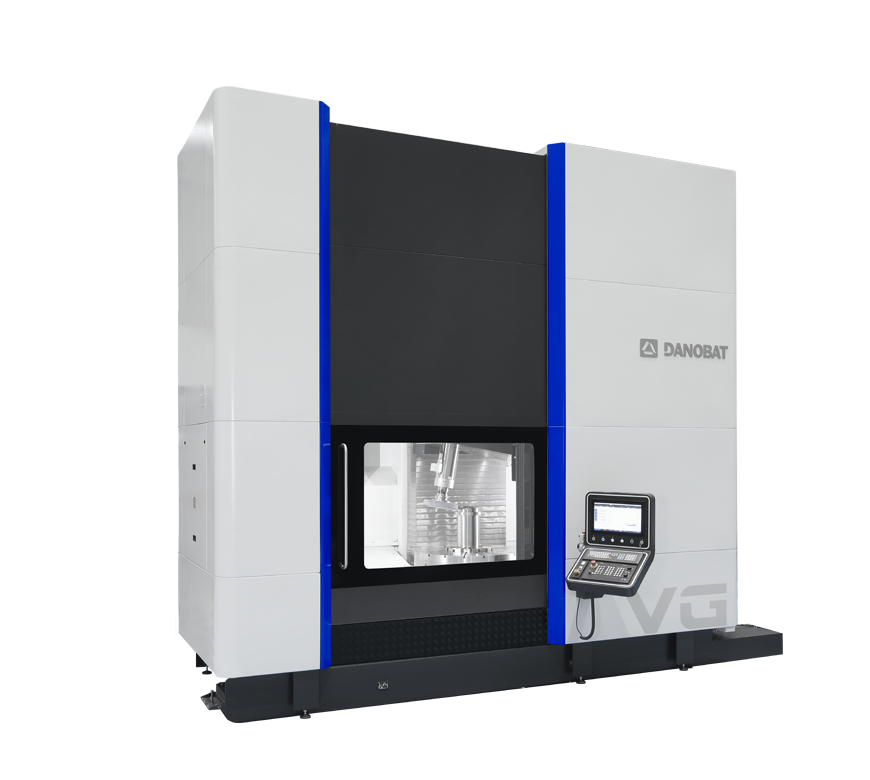

VGVertical grinding machine with moving table

VGVertical grinding machine with moving table -

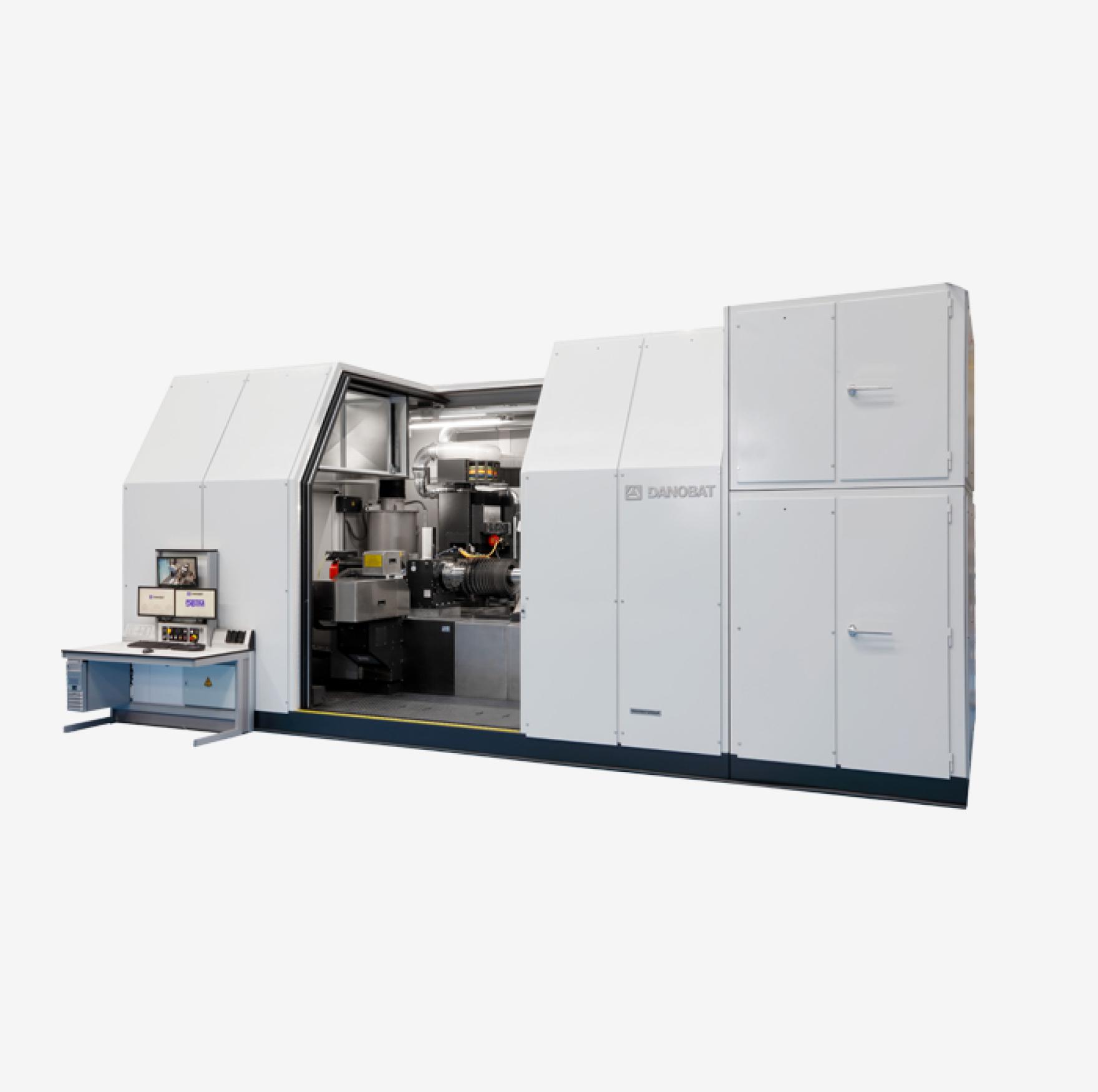

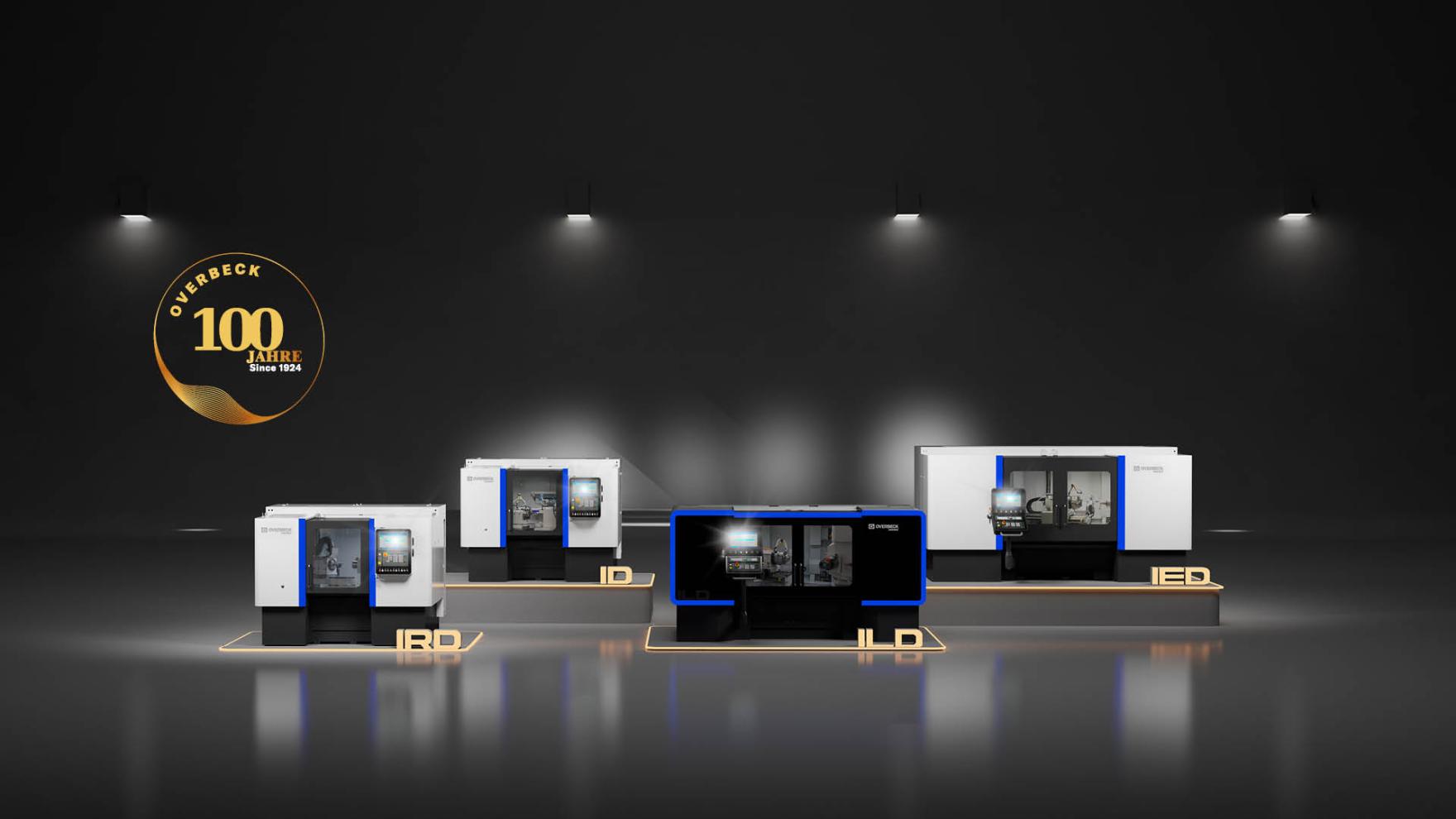

ILDInternal and universal grinding machine

ILDInternal and universal grinding machine -

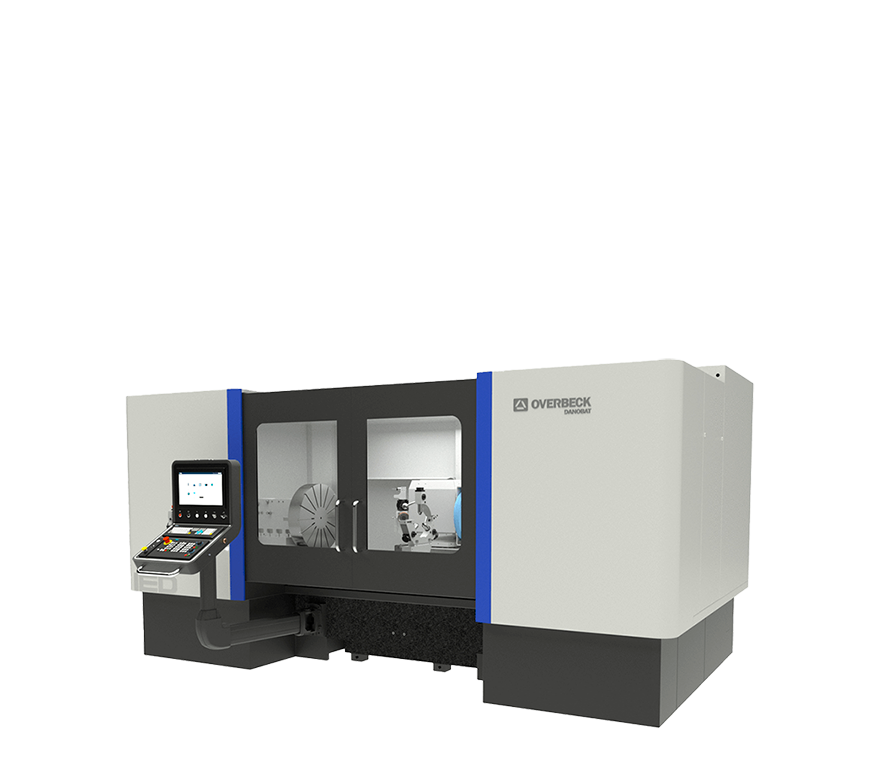

IRDInternal, external and radius grinding machine

IRDInternal, external and radius grinding machine -

EstartaCenterless grinding machine

EstartaCenterless grinding machine -

CGCompact grinding machine for high production

CGCompact grinding machine for high production -

IEDSimultaneous internal and external grinding machine

IEDSimultaneous internal and external grinding machine -

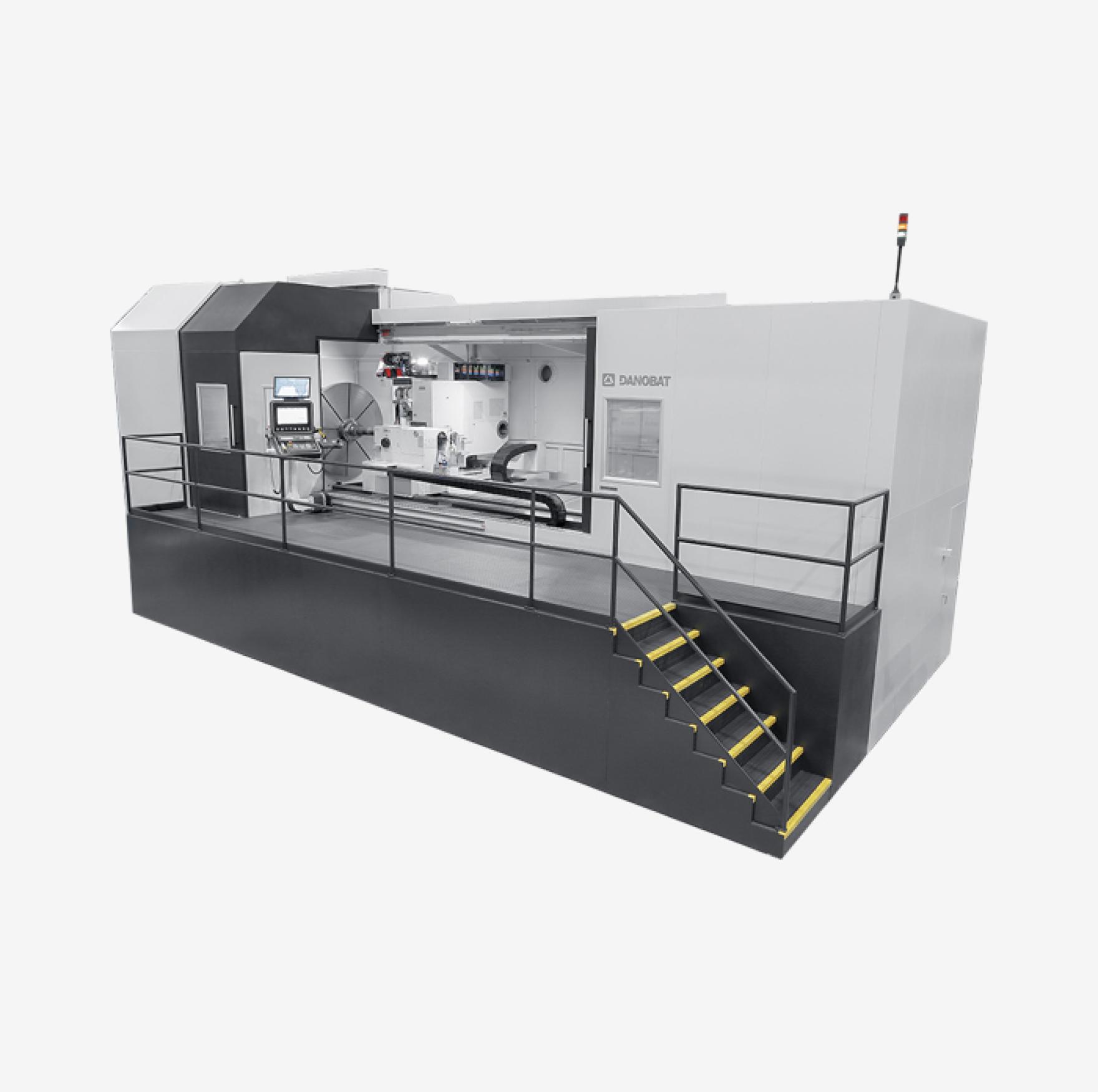

HGHighest precision heavy duty grinding machine

HGHighest precision heavy duty grinding machine -

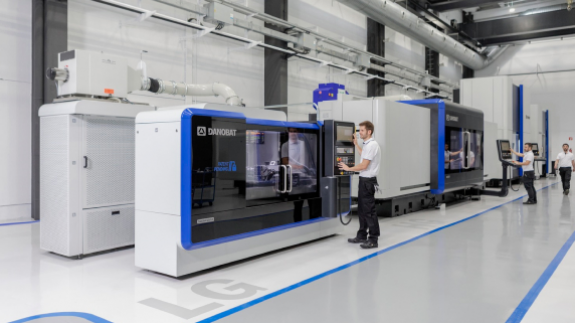

LGVersatile and high-speed production grinding machine

LGVersatile and high-speed production grinding machine -

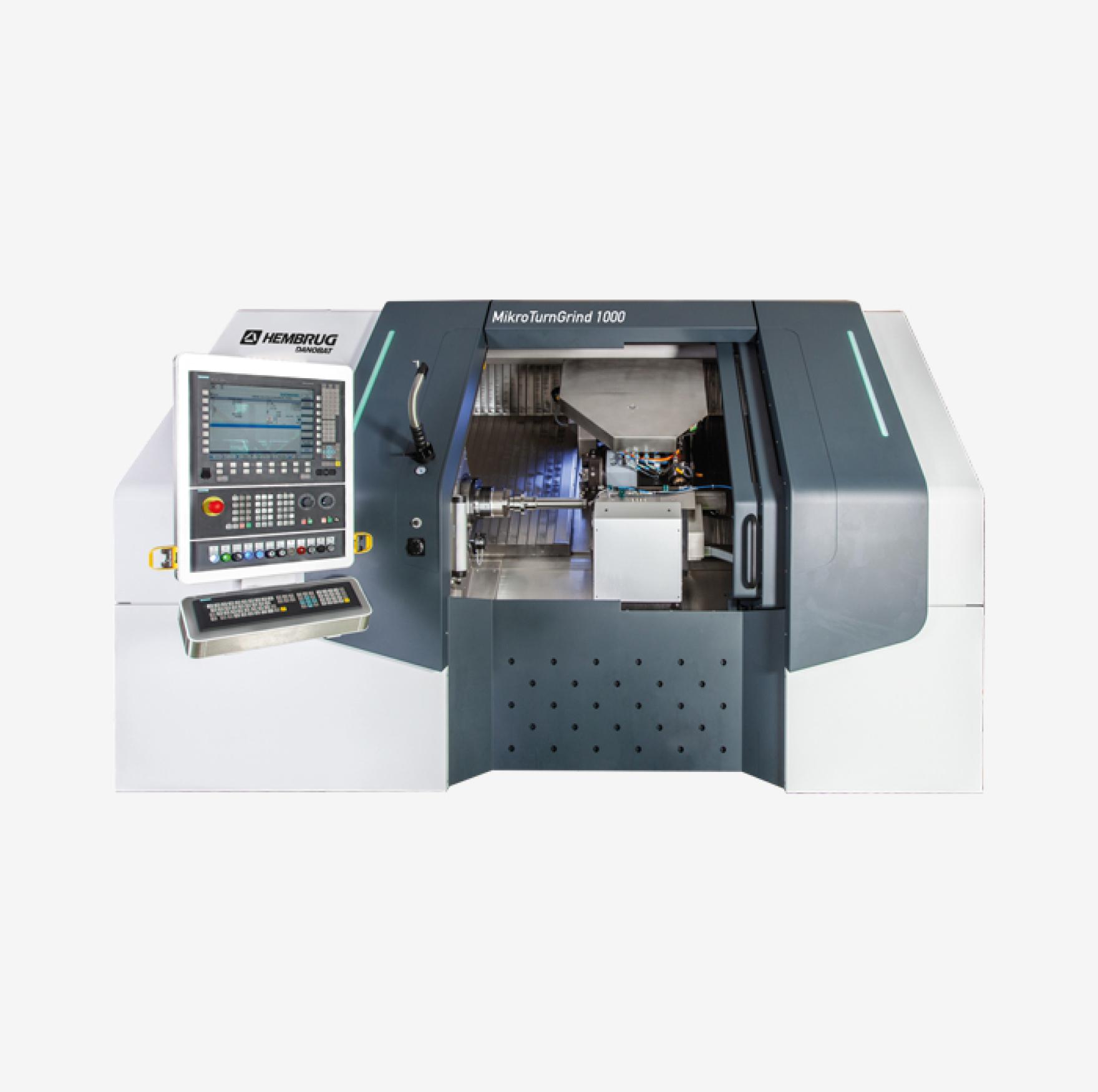

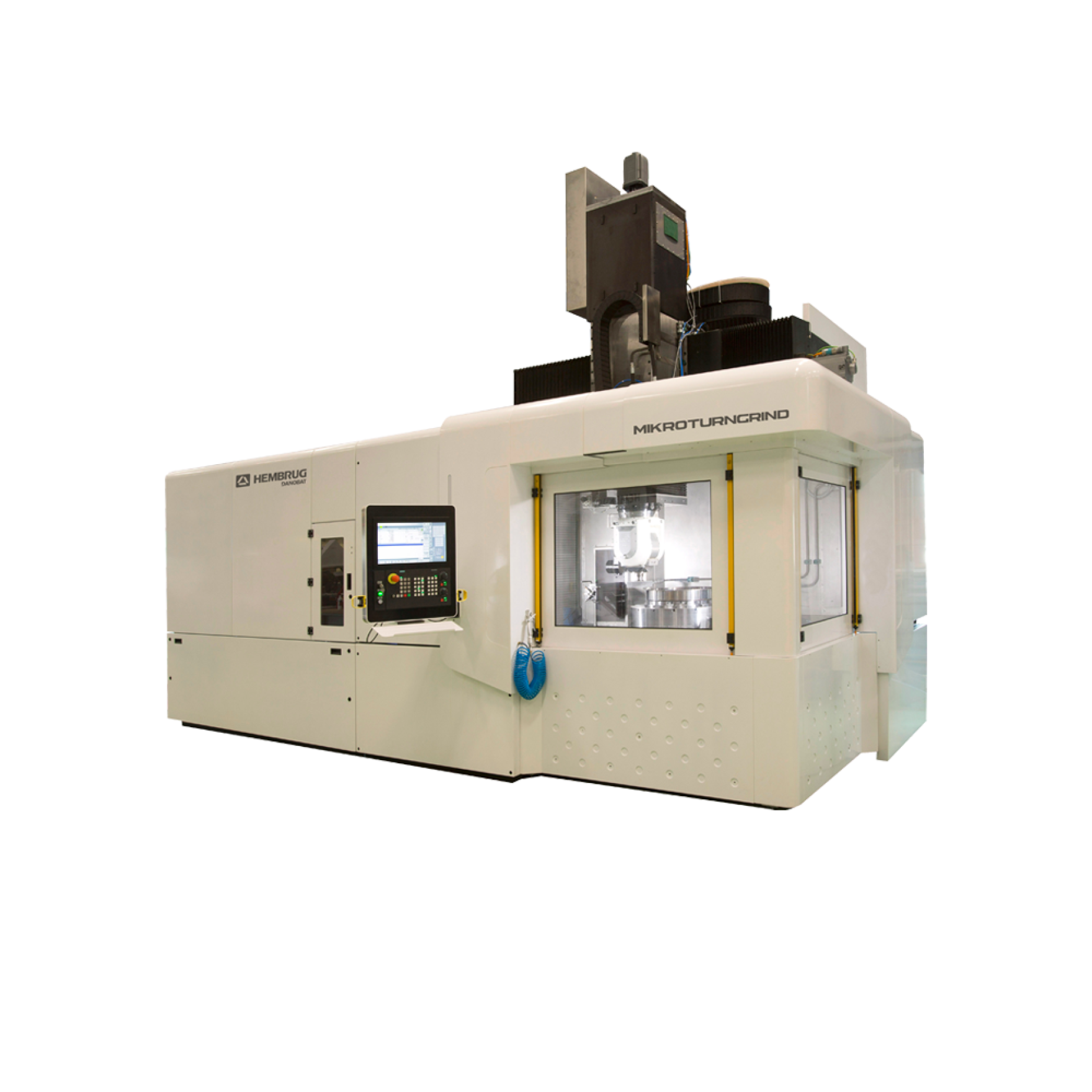

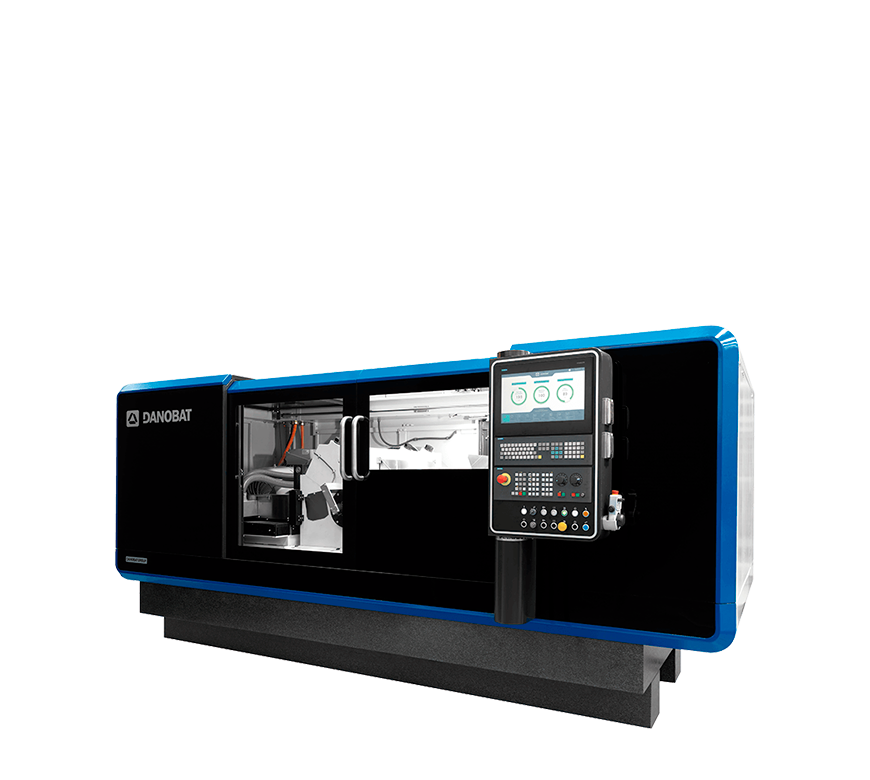

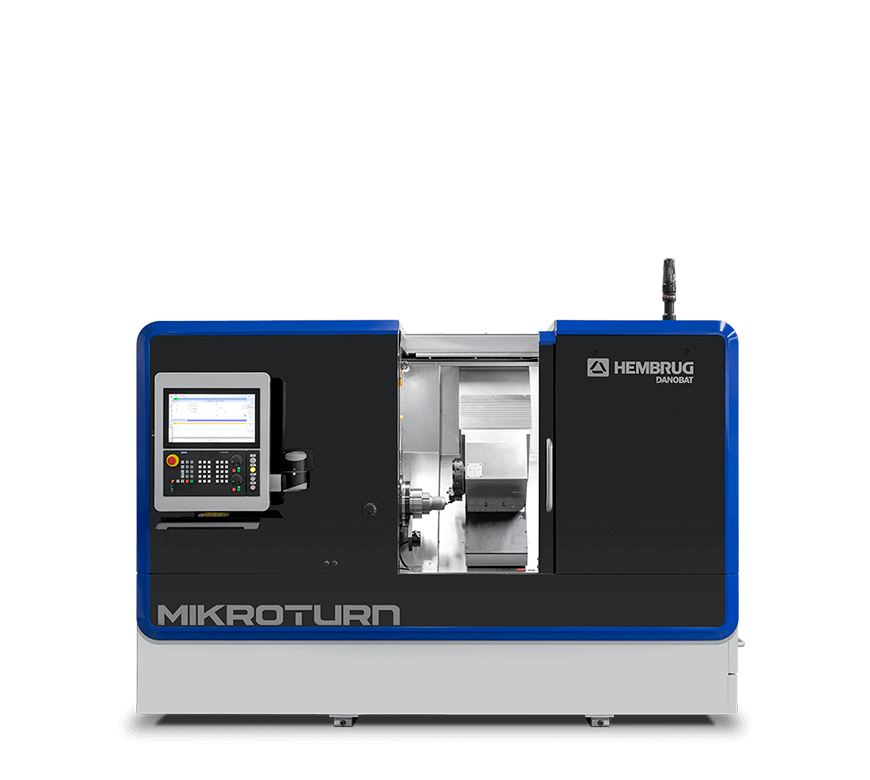

Mikroturn®High precision horizontal hard turning machine

Mikroturn®High precision horizontal hard turning machine -

DPL/DPL-JPortal lathe for wheelset reprofiling and brake disc turning

DPL/DPL-JPortal lathe for wheelset reprofiling and brake disc turning

With over 70 years of expertise, Danobat is a global leader in manufacturing innovative equipment, including precision grinding machines, lathes, and robotic systems for machining.

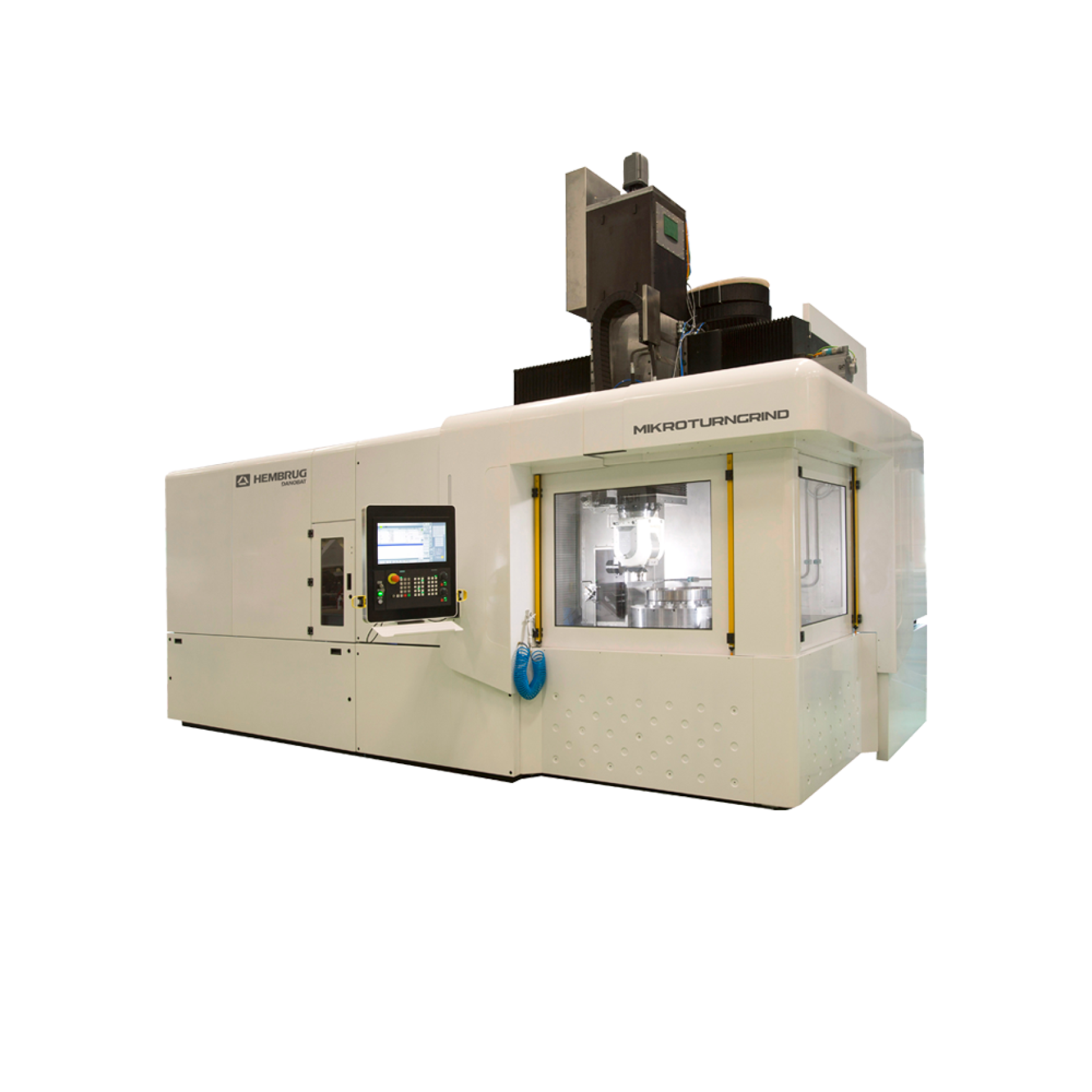

Hembrug is a Dutch leader in ultra precision hard turning lathes and hybrid machines, bringing its fine turning and grinding capabilities to the forefront.

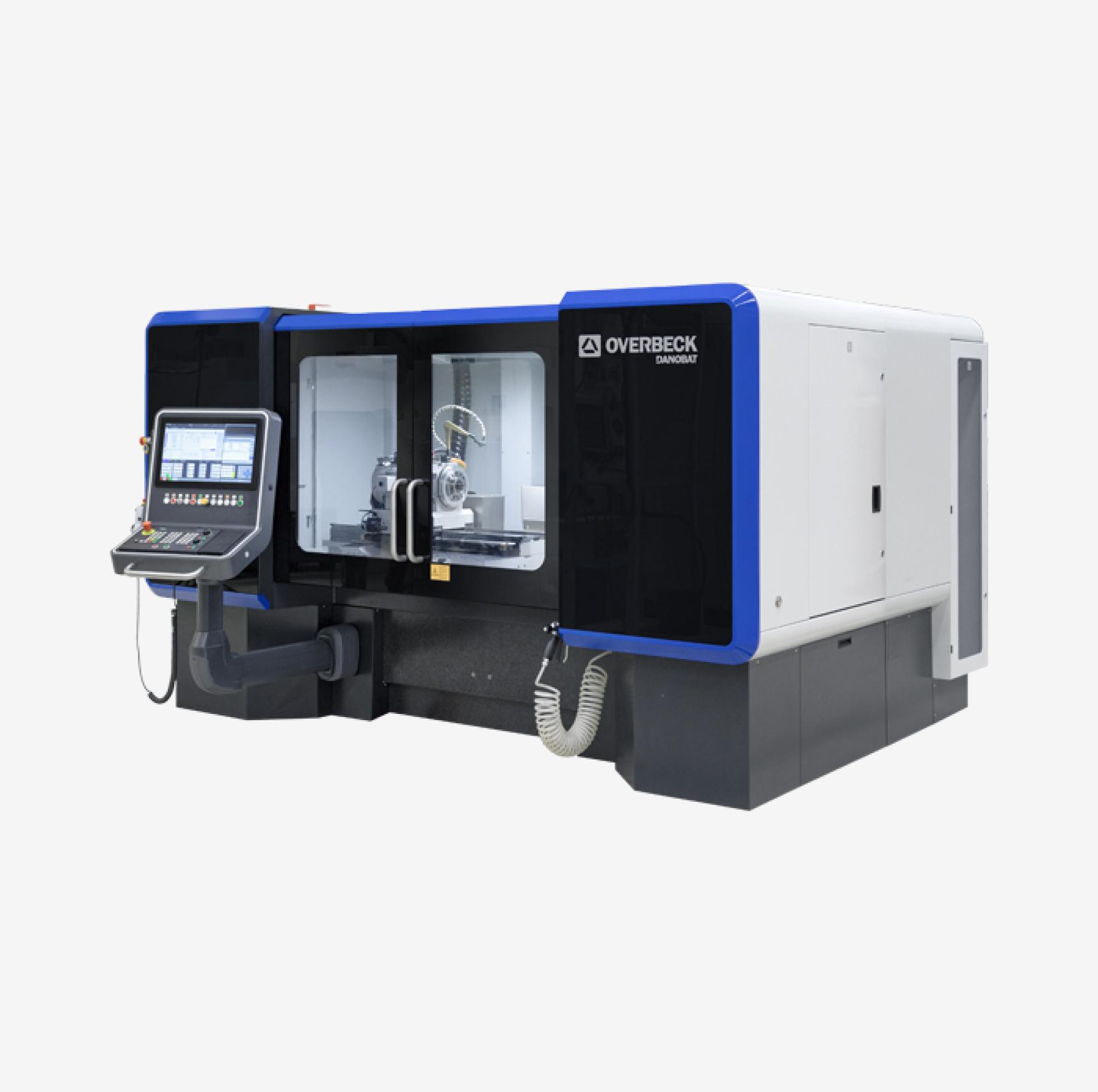

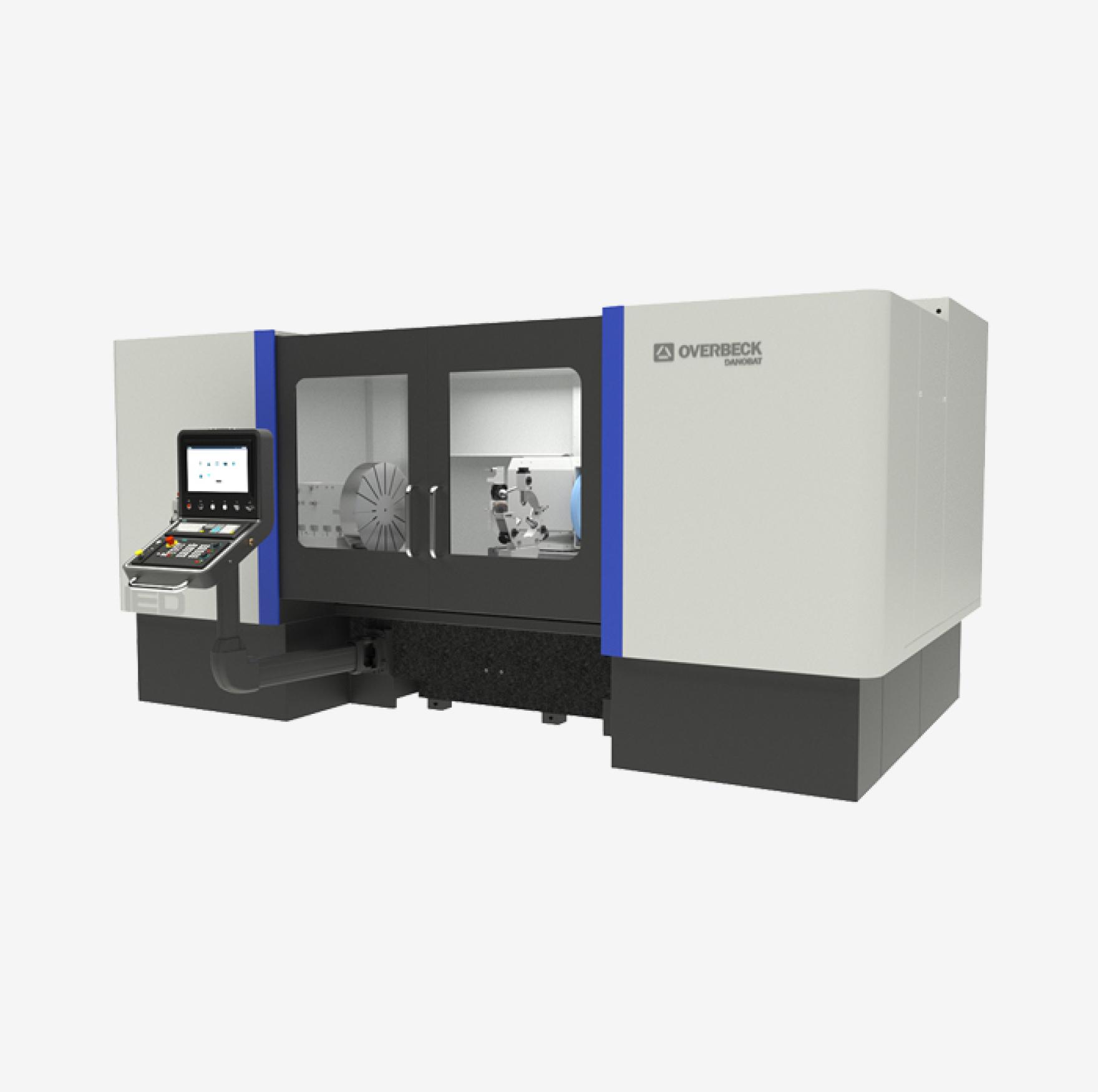

With a century of proven excellence, Overbeck stands as a distinguished German manufacturer focused on high-precision internal grinding machines.

We automate the processes of manufacturing aerostructure parts with CNC precision robotics.

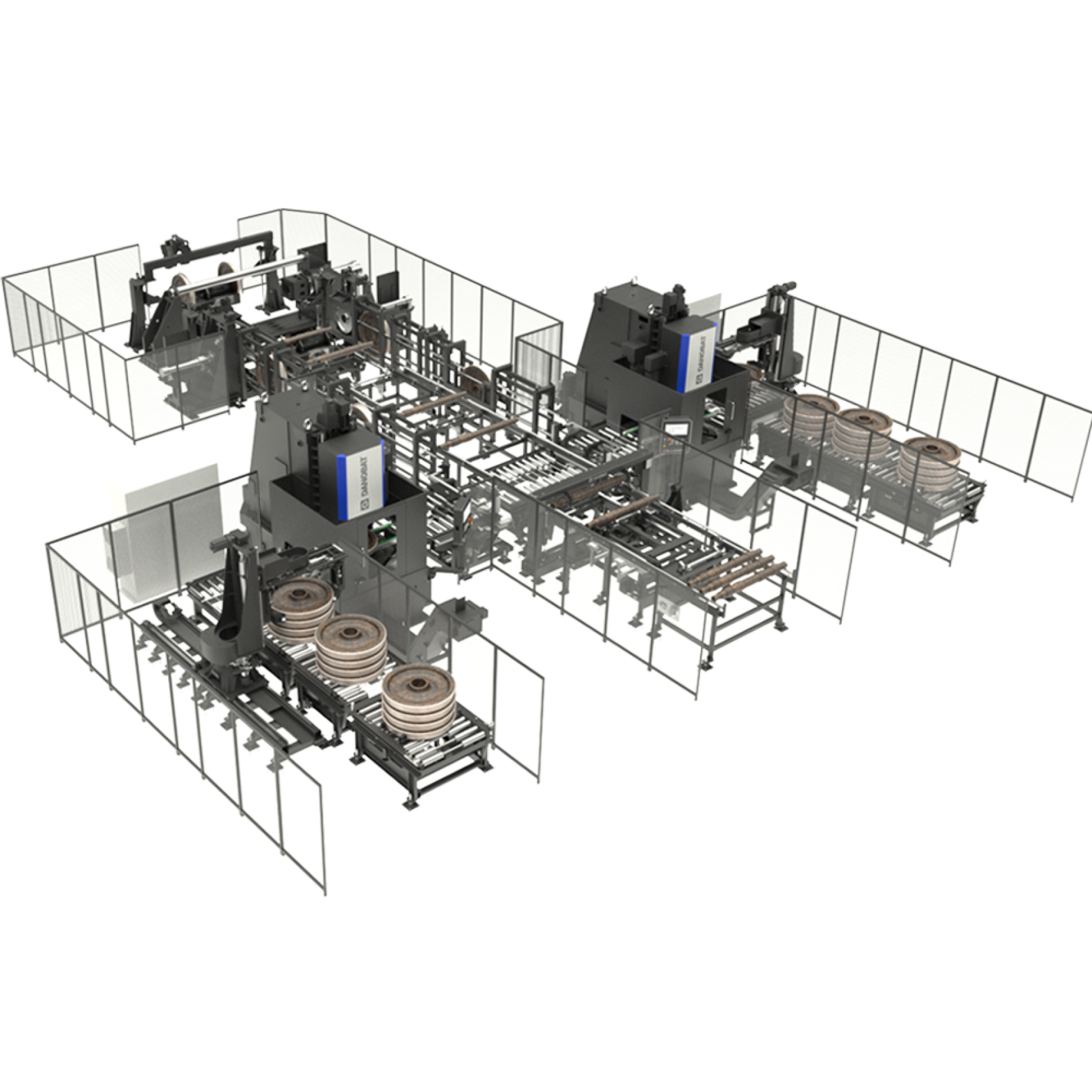

Workpiece loading and unloading, feeding systems and additional stations.