Email us

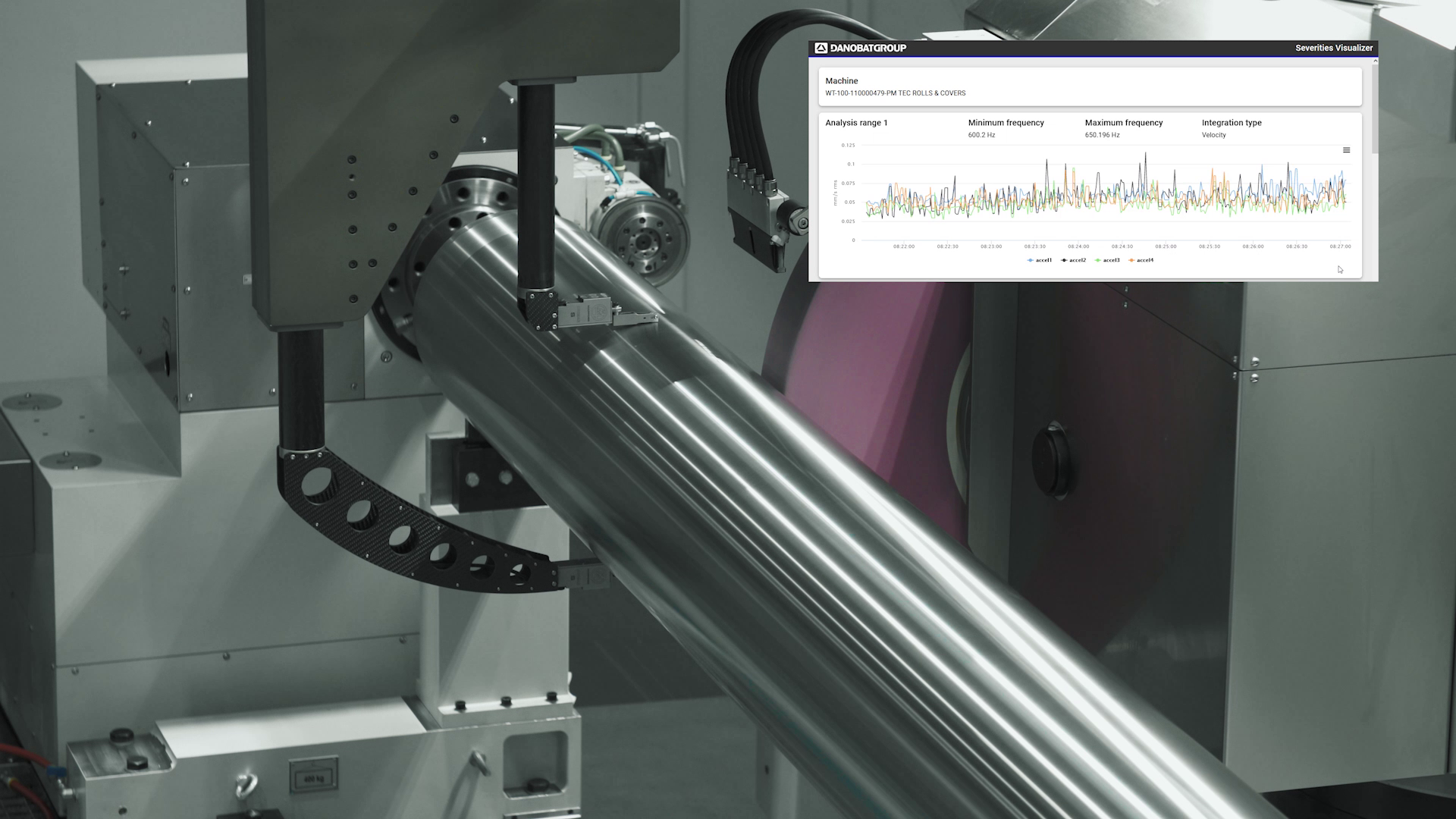

Do you know the vibration mitigation system?

VMIS is a system to prevent vibrations that occur when grinding parts.

VMIS is a system to prevent vibrations that occur when grinding parts.

It consists of three aspects.

- Vibration measurement system

- Anti-vibration system

- Monitoring system

Vibration measurement system

It has several accelerometers, a controller, and dedicated software. The accelerometers are placed on the machine parts that are most significant during the grinding process. They record signals which, afterwards, are processed in a controller.

Anti-vibration Action System

This system is based on the machine's HMI and CNC. Here the actions to be taken by the machine at different vibration levels are defined.

The software allows the execution of different actions: for example, to change the variables of the grinding process or to interrupt it (for dressing or other final processes).

Vibration monitoring

The machine displays, at every moment, the vibration level of the accelerometers at different frequencies. With this information, we know the vibrations of the grinding process and, based on the data, the machine can act on them.

Benefits of the VMIS system

- To avoid the traces produced by vibration on the surface of the part

- To reduce operator intervention in long grinding processes is reduced

- To use more aggressive grinding processes from the beginning: the moment vibrations are detected, the machine can modify the process variables to smooth the process